Washing device and its operation controlling method

A washing device and operation control technology, which is applied to washing devices, washing machines with containers, textiles and papermaking, etc., can solve the problems of washing unwashable objects, increasing production costs, and insufficient installation space, so as to prevent power consumption and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, the present invention is described in further detail in conjunction with accompanying drawing and specific embodiment:

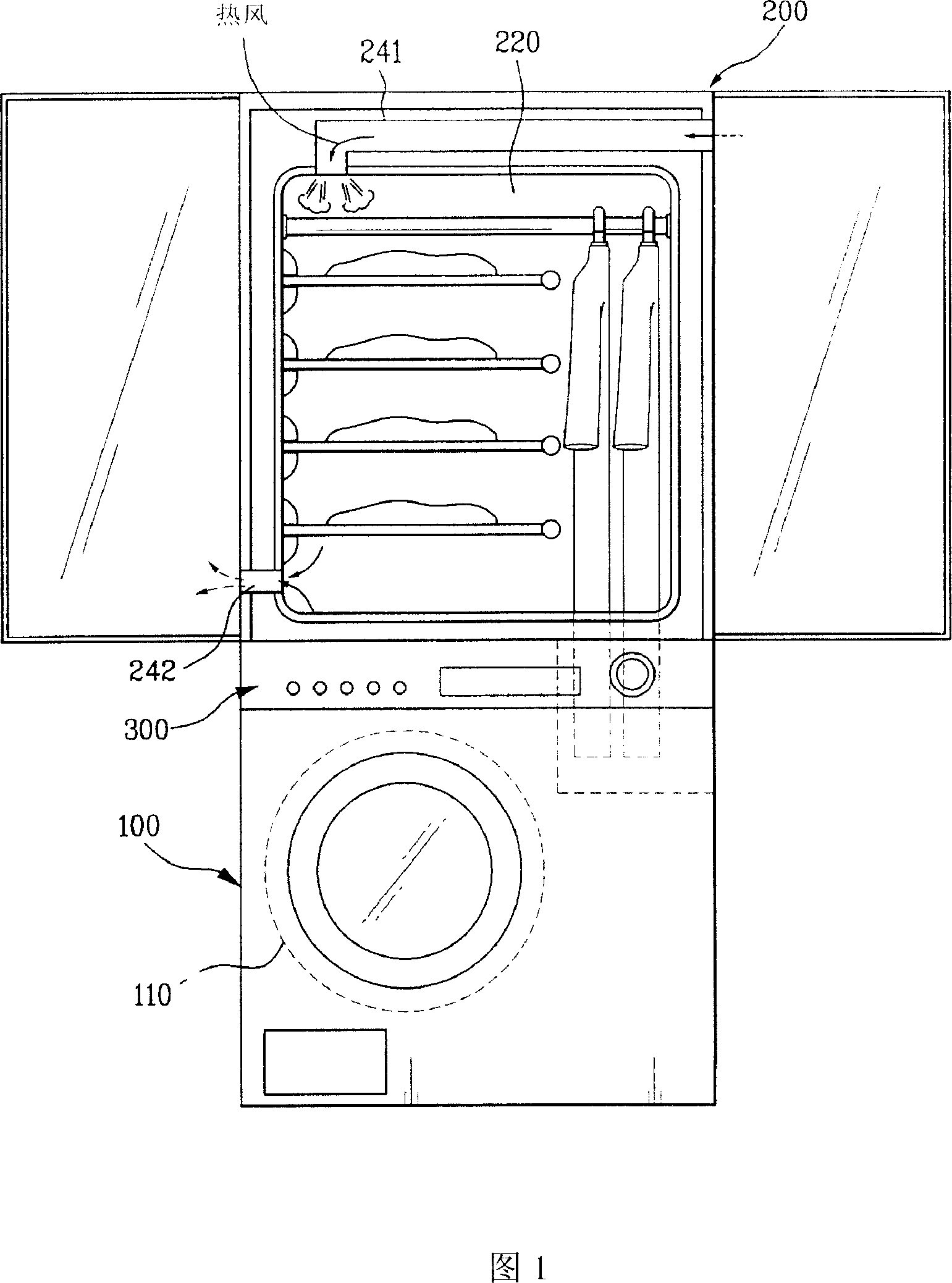

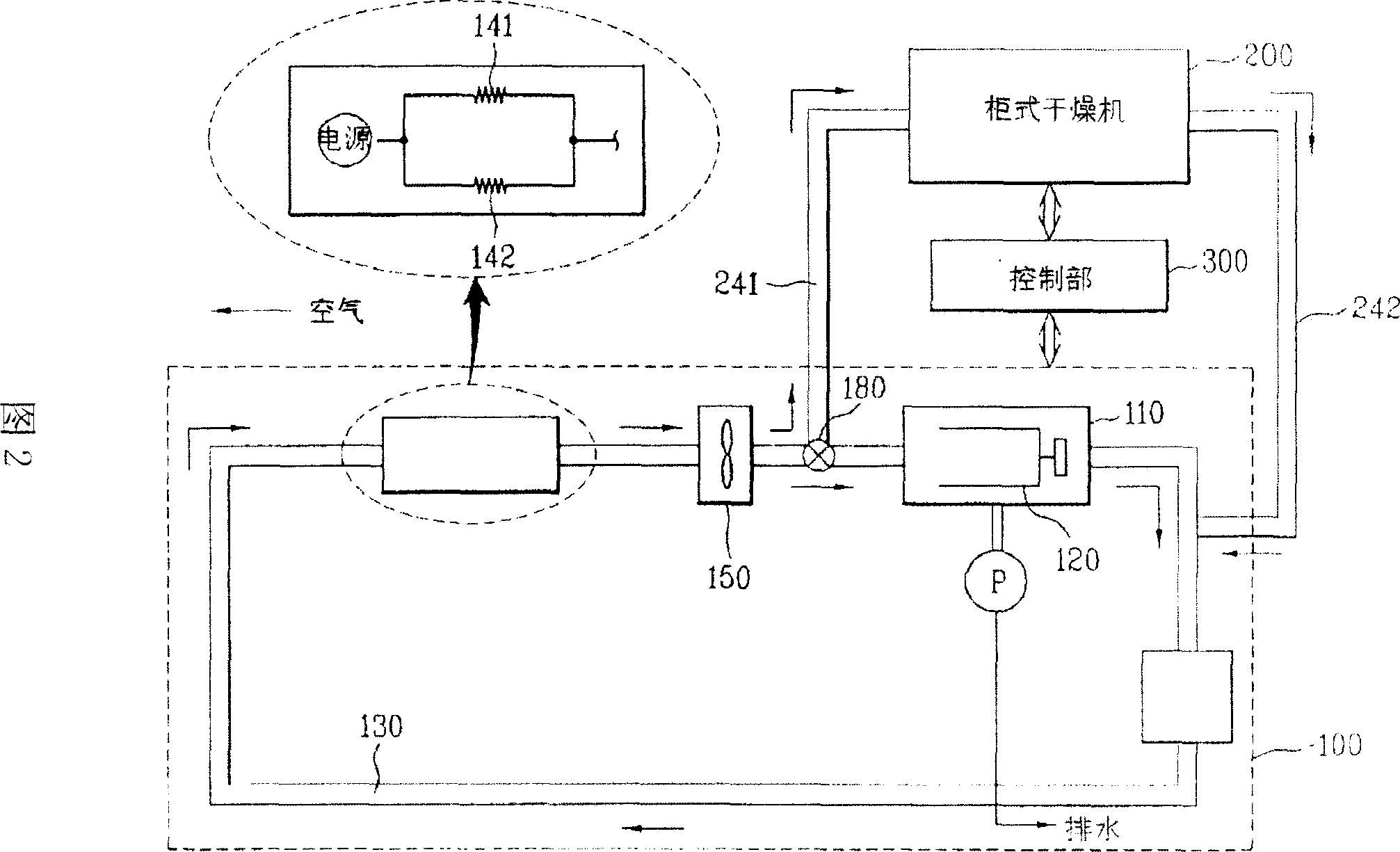

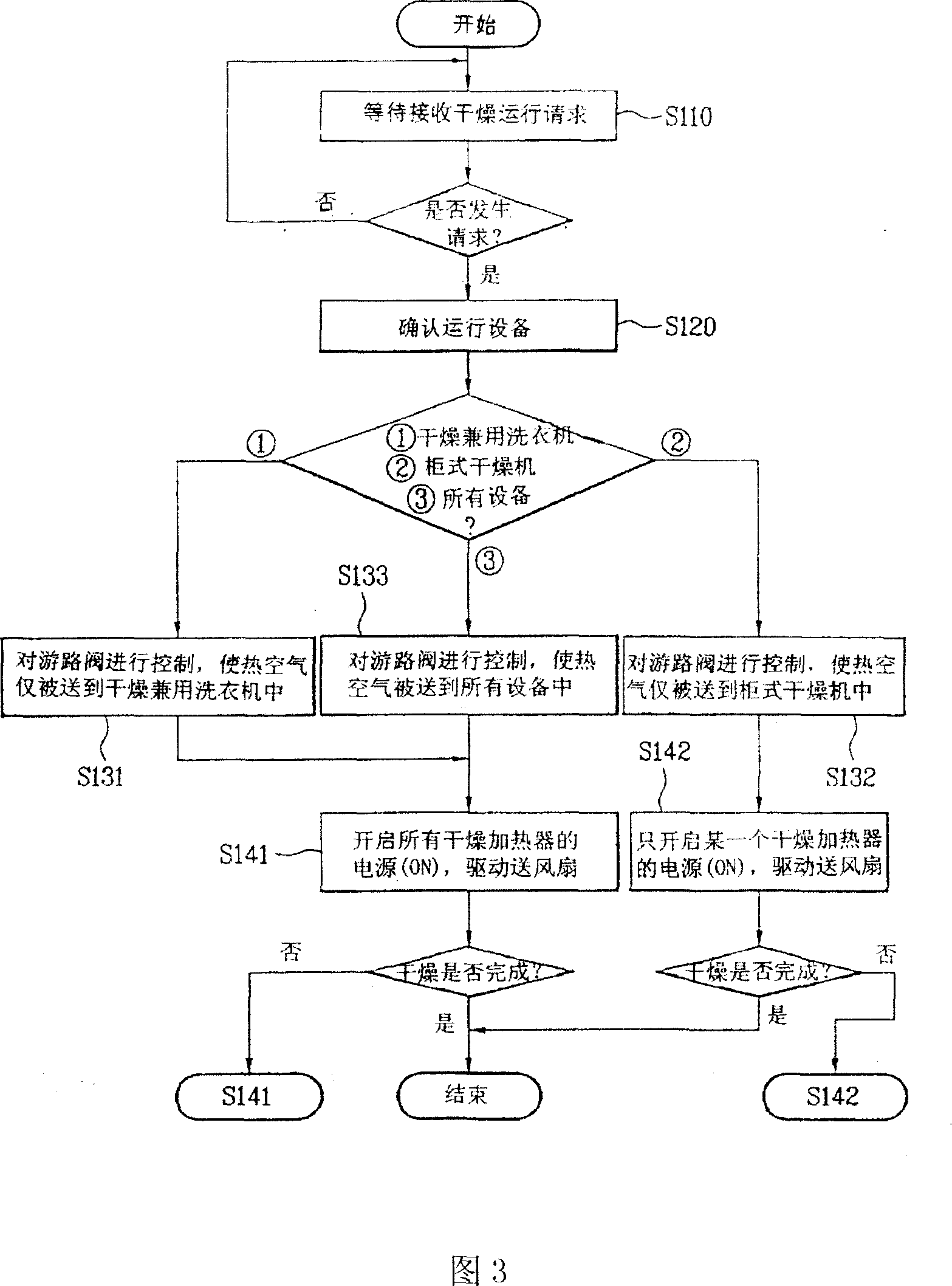

[0040] As shown in FIGS. 1 and 2 , the washing machine of the present invention includes a washing machine 100 , a cabinet dryer 200 and a control unit 300 .

[0041] Wherein, the combined drying washing machine 100 includes a washing tub 110, a drum 120, a hot air supply pipe 130, drying heaters 141, 142, and a blower fan 150; it can wash and dry laundry.

[0042] The drum 120 is installed inside the washing tub 110 in a manner capable of rotating and stirring, and can perform washing and drying operations in a state where laundry is put in.

[0043] In addition, the hot air supply pipe 130 is used to guide hot air in a high temperature state to flow into the drum 120 . The air inside the washing tub 110 may be circulated and re-supplied to the inside of the washing tub 110 after being received.

[0044] Meanwhile, the drying heaters 141 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com