Double-impeller cycloid wheel decelerator

A wheel reducer, cycloidal wheel technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve the problems of affecting accuracy, reducing efficiency, poor stability, etc., to improve transmission accuracy and transmission stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

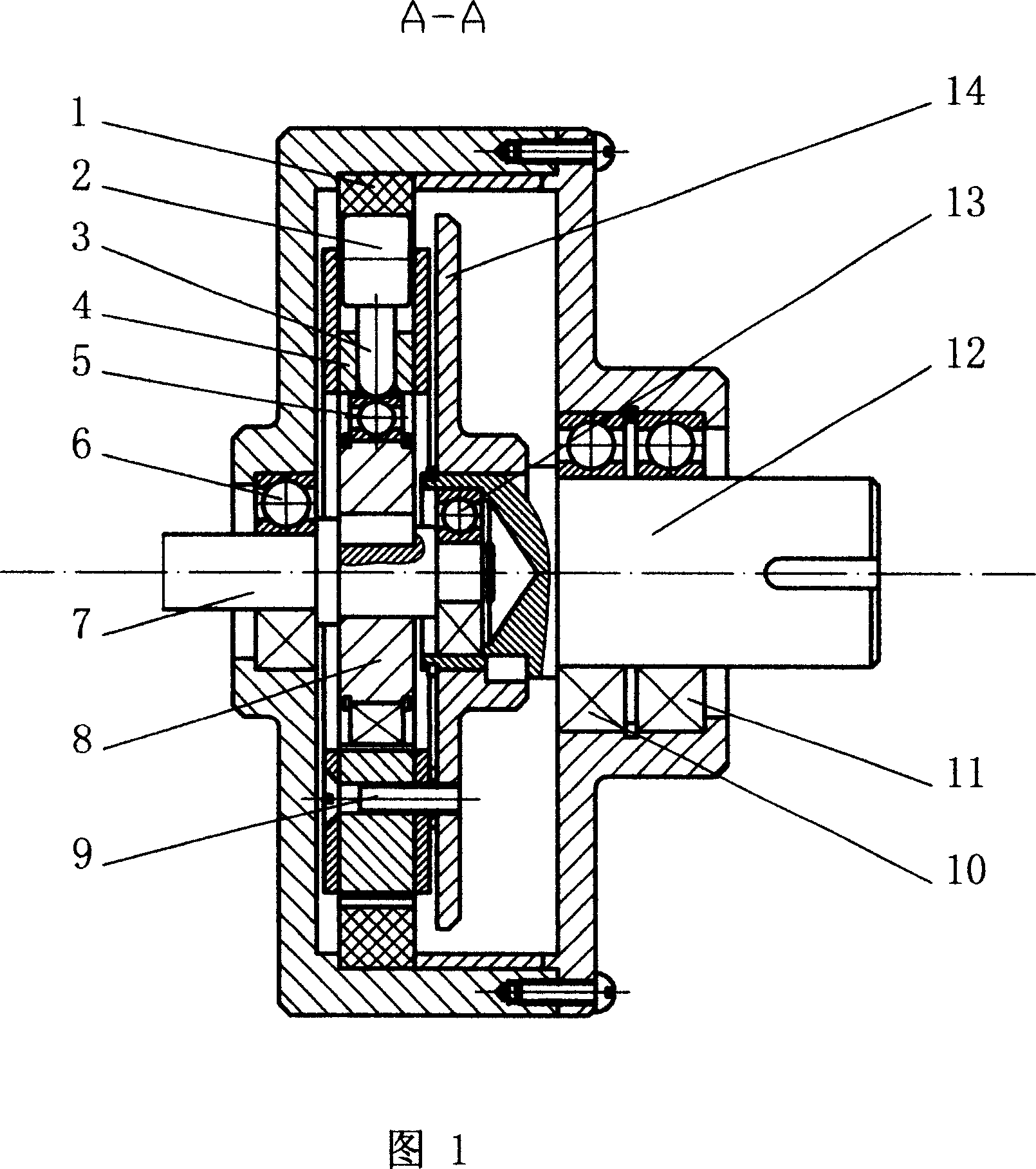

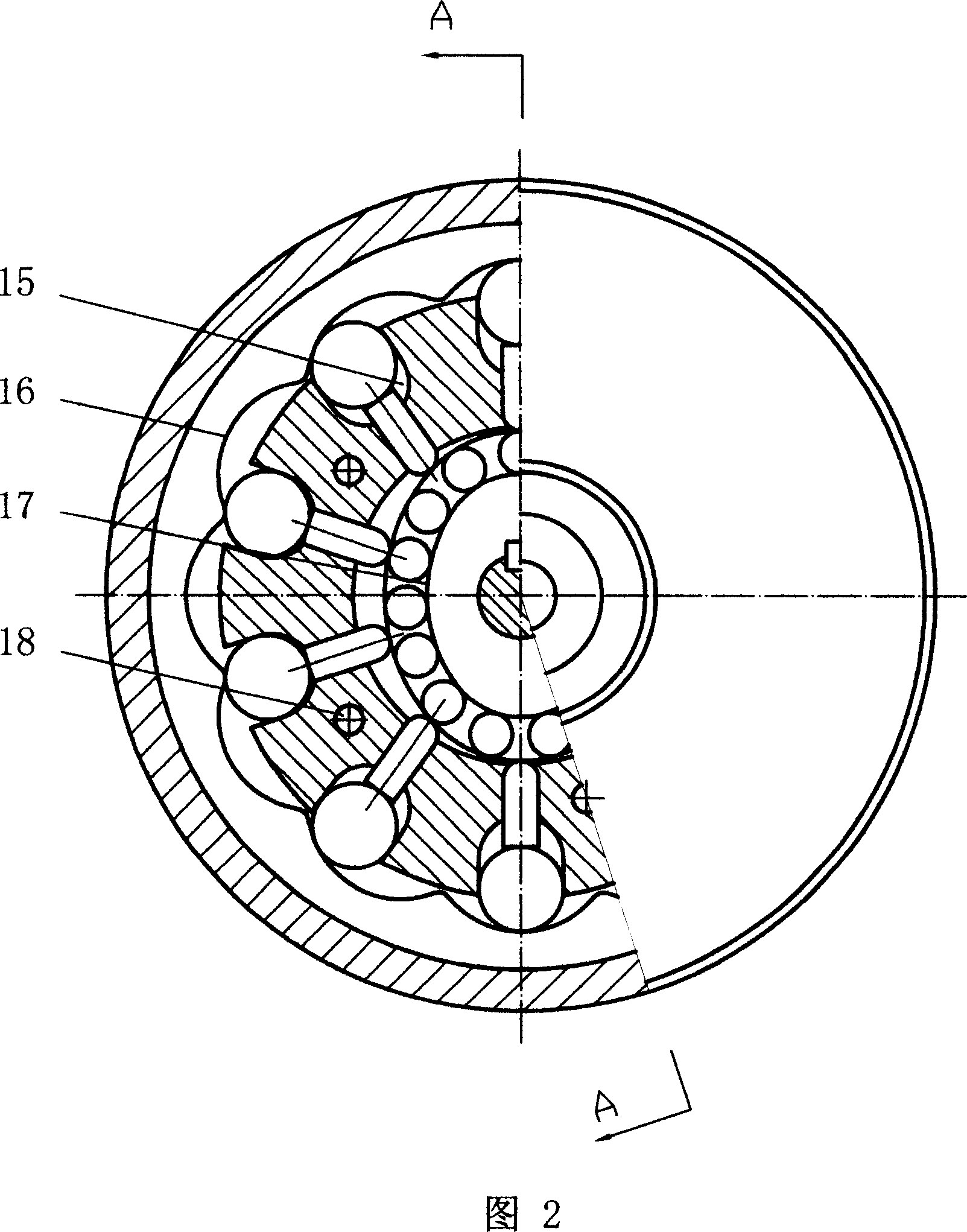

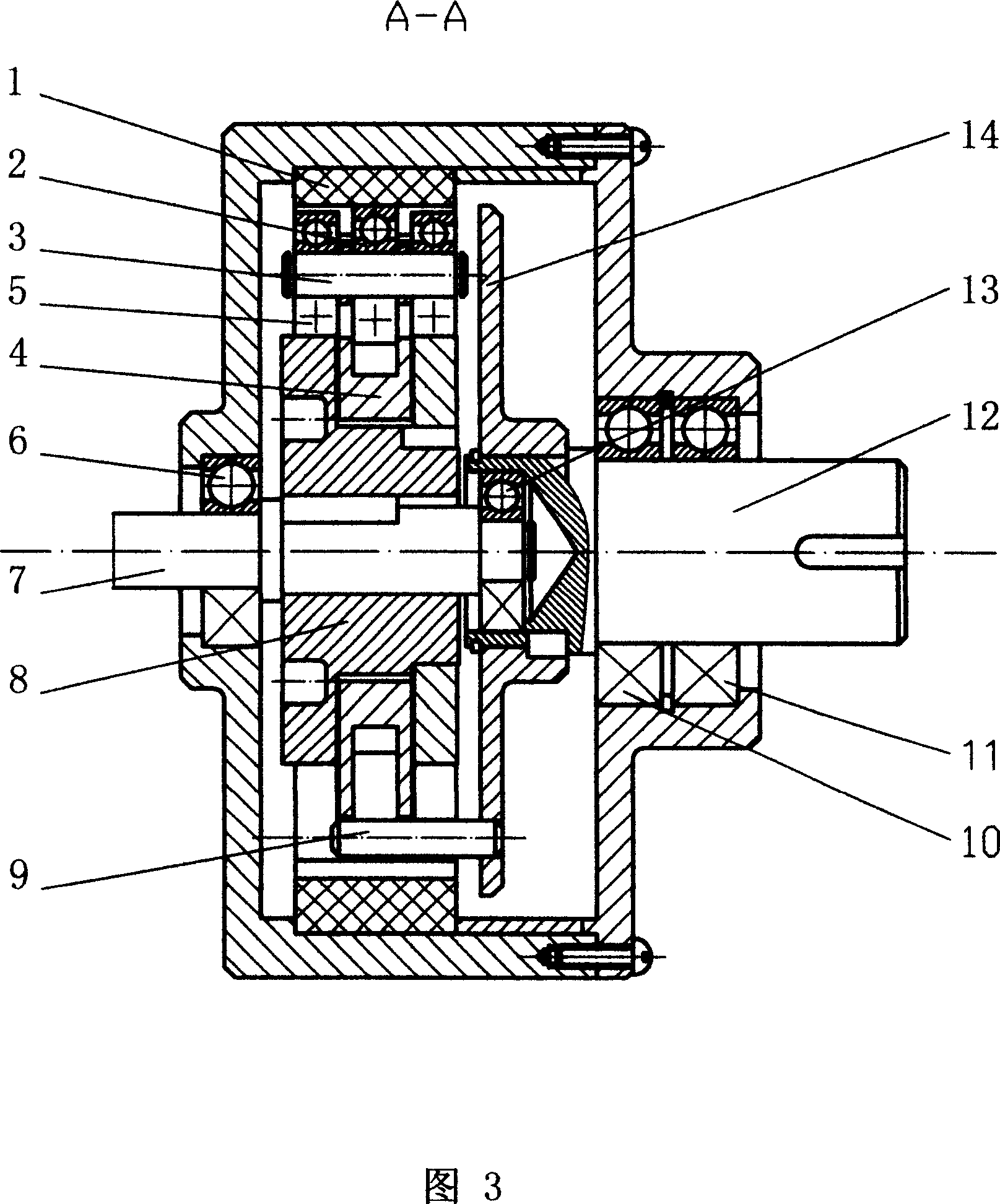

[0019] In Figures 1, 2, 3, 4, the cycloid 1 is fixed on the inside of the main body shell, and the inner side engages with the roller 2; the wave generator 8 is located in the middle of the main body, is fixed on the input shaft 7, and is sheathed with the drive disc 4; 4 is provided with a driving groove 15 radially and evenly distributed on the circumference. A freely slidable shaft pin 3 and a roller 2 are installed in the driving groove 15; the roller 2 is in a form with the shaft pin 3, the shaft pin 3 and The flexible ball bearing 5 on the wave generator is slidingly matched, one form is matched with the shaft pin 3, the shaft pin 3 is rotated with the flexible ball bearing on the shaft pin 5 (Figure 3), and the other forms of flexible ball bearing 5 (Figure 3) are matched with The wave generator 8 is in rolling fit; the rotating arm 14 is fixedly connected to the drive disc 4 and the output shaft 12 through the pin hole 18 and the pin 9, and forms an output mechanism throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com