Resistor for controlling load circuit and its assembly method and wiring board

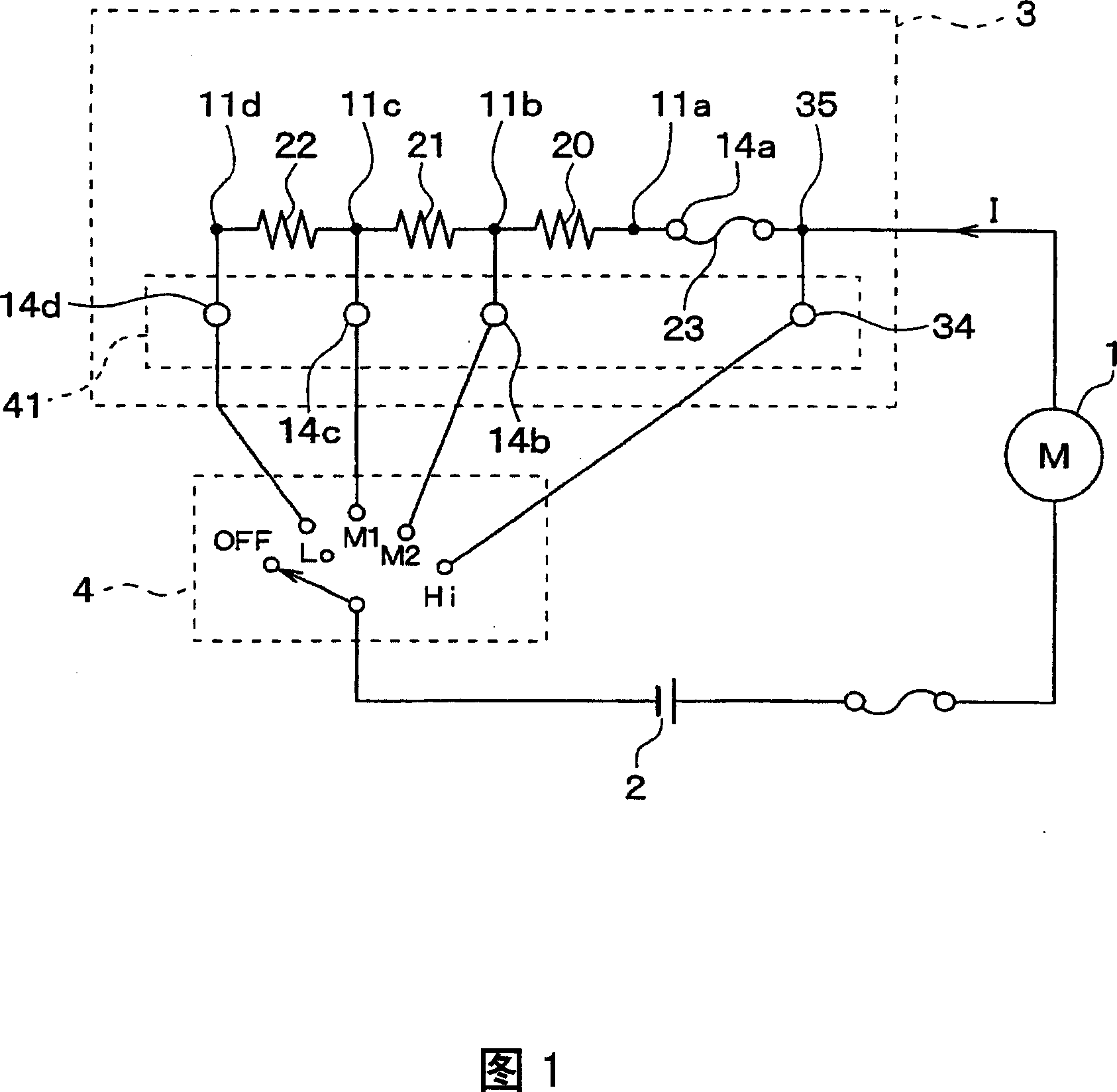

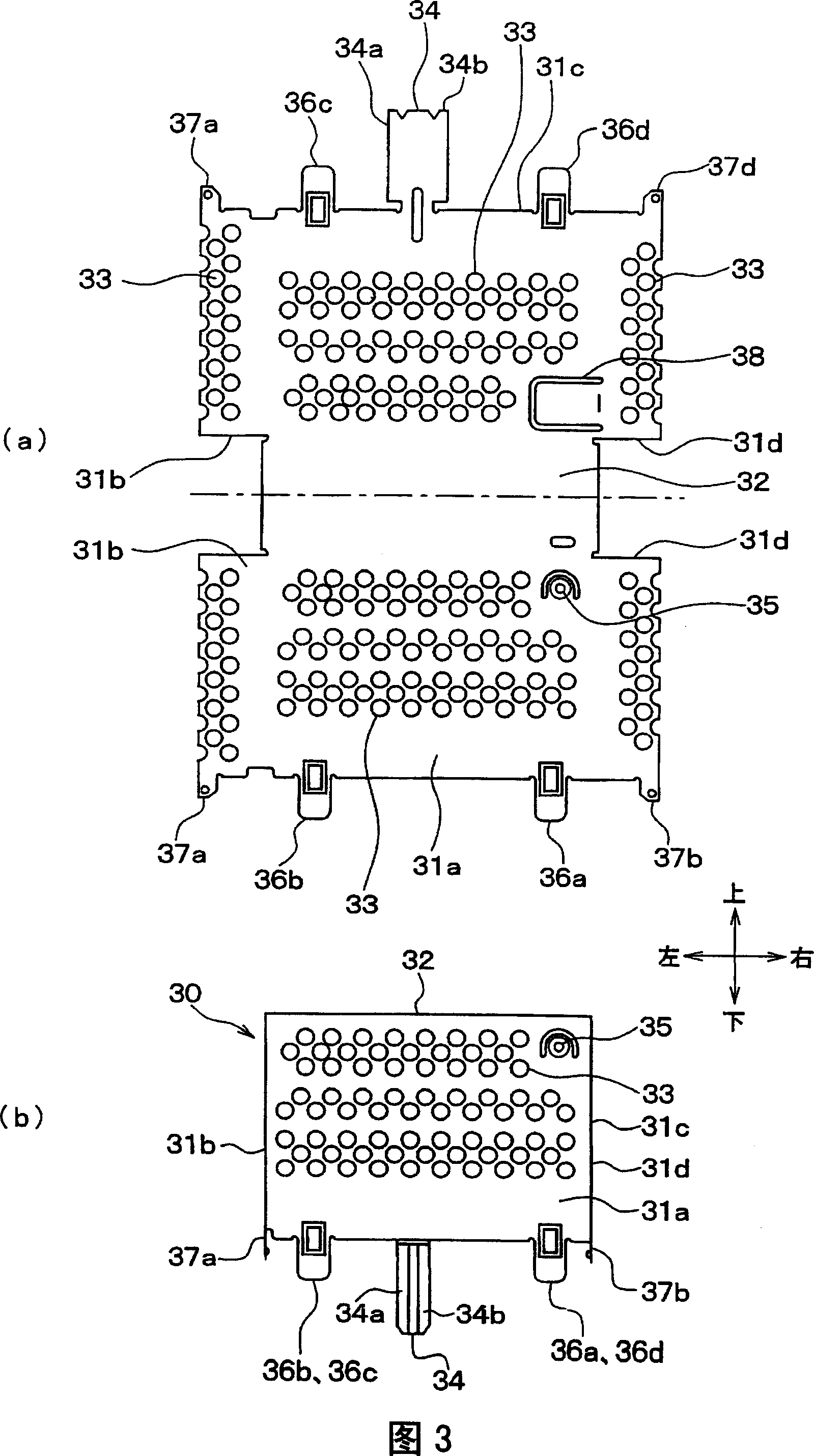

A load current and resistor technology, applied in excitation or armature current control, other resistor networks, resistor terminals/electrodes, etc., can solve the problems of assembly process or man-hours and the number of components, and achieve the effect of compact length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

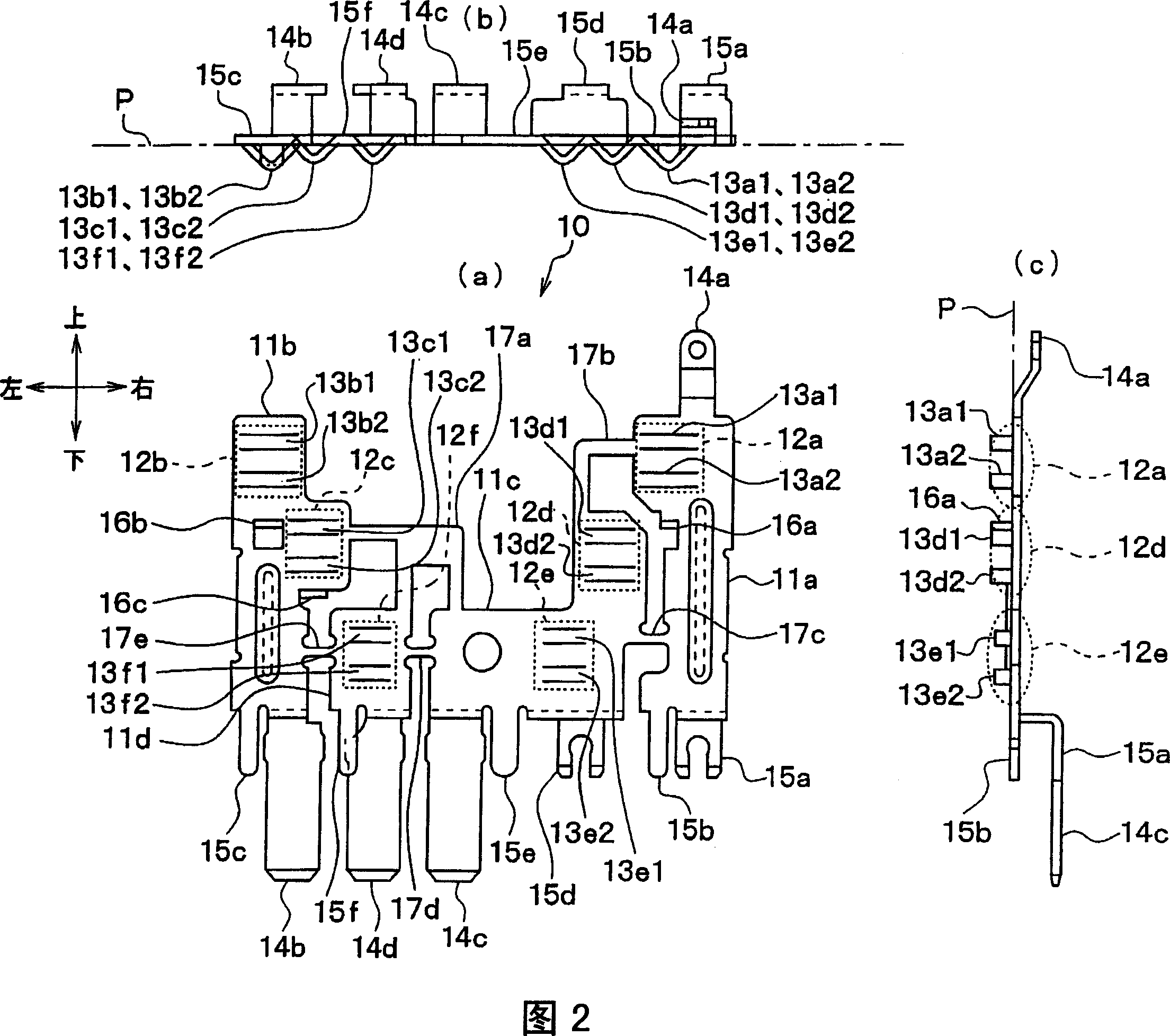

[0103] (1) In the above-mentioned present embodiment, in order to make the first to sixth flat plate parts 12a to 12f of the lead parts 20a to 22b fixing the three resistors 20 to 22 all be located on the same plane P, the 40 is an example in which the first to fourth wiring members 11a to 11d are arranged in a row in the horizontal direction, but the present invention is not limited thereto.

[0104] That is, for example, it may be arranged such that only the two flat plate parts 12e, 12f of the pair of lead parts 22a, 22b fixing the third resistor 22 are located on the same plane, and the pair of lead parts 21a, 21b of the second resistor 21 are fixed on the same plane. The two flat plate parts 12c, 12d are located on another same plane parallel to the above-mentioned plane. Furthermore, the two flat plate parts 12a, 12b which fix the pair of lead part 20a, 20b of the 1st resistor 20 can also be arrange|positioned so that it may be located on another same plane similarly. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com