Composite footwear insole, and method of manufacturing same

An insole and rear technology, applied in the field of synthetic insole and its manufacturing, can solve the problems of reducing stress absorption effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

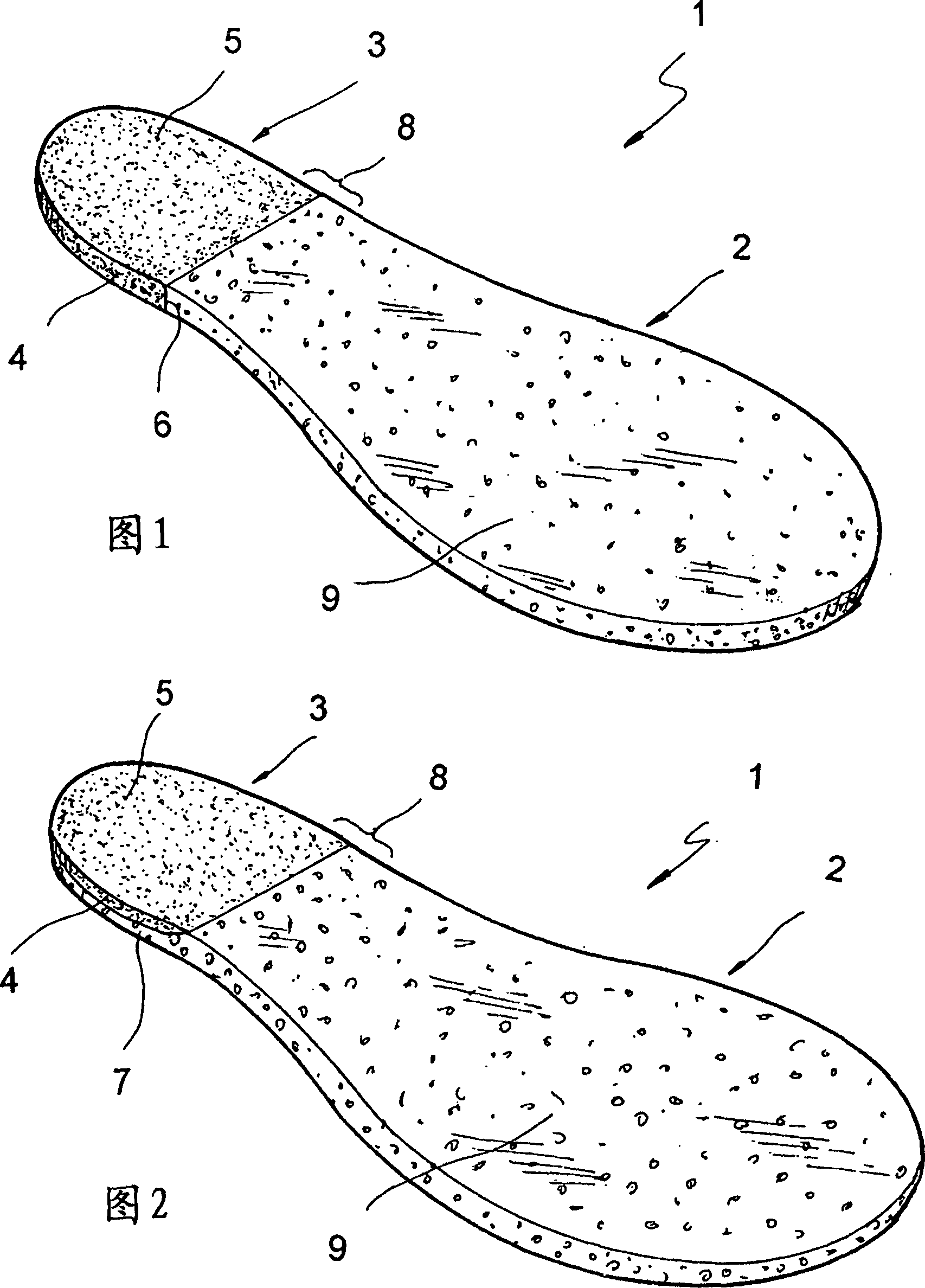

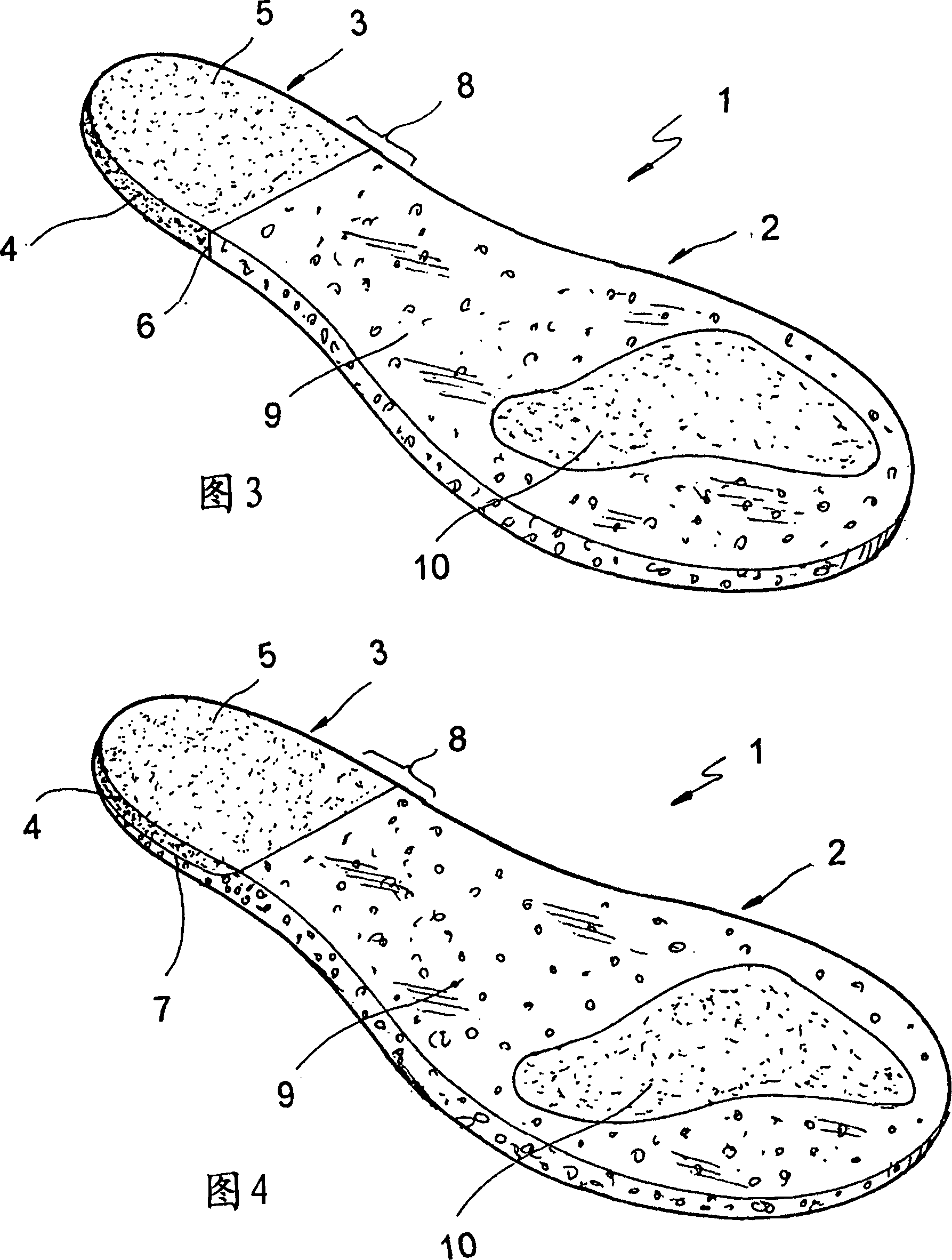

[0020] A synthetic insole according to the invention, designed for various types of footwear and generally designated by the numeral 1, according to the invention is described with particular reference to the above-mentioned figures.

[0021] The insole 1 has a front part 2 intended to interact with the foot in the area of the metatarsals and at least partly in the area of the arch, and a rear part 3 for interacting with the heel.

[0022] A characteristic feature of the invention is that this rear part 3 has a gel layer 4 whose planar dimensions are approximately equal to those of the rear part 3 itself. Thereby, the heel can be supported evenly, and the stress thereon can be effectively absorbed.

[0023] The gel layer 4 may have an upper surface 5 intended to interact with the heel, the upper surface 5 being substantially continuous without surface discontinuities in order to further enhance comfort. Furthermore, the gel layer 4 may be formed from a single piece of one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com