Method for producing expanded metal profiles and profile produced by the method

A technology for metal profiles and profiles, which is used in the production of expanded metal profiles and can solve problems such as jeopardizing strength and weakening profiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

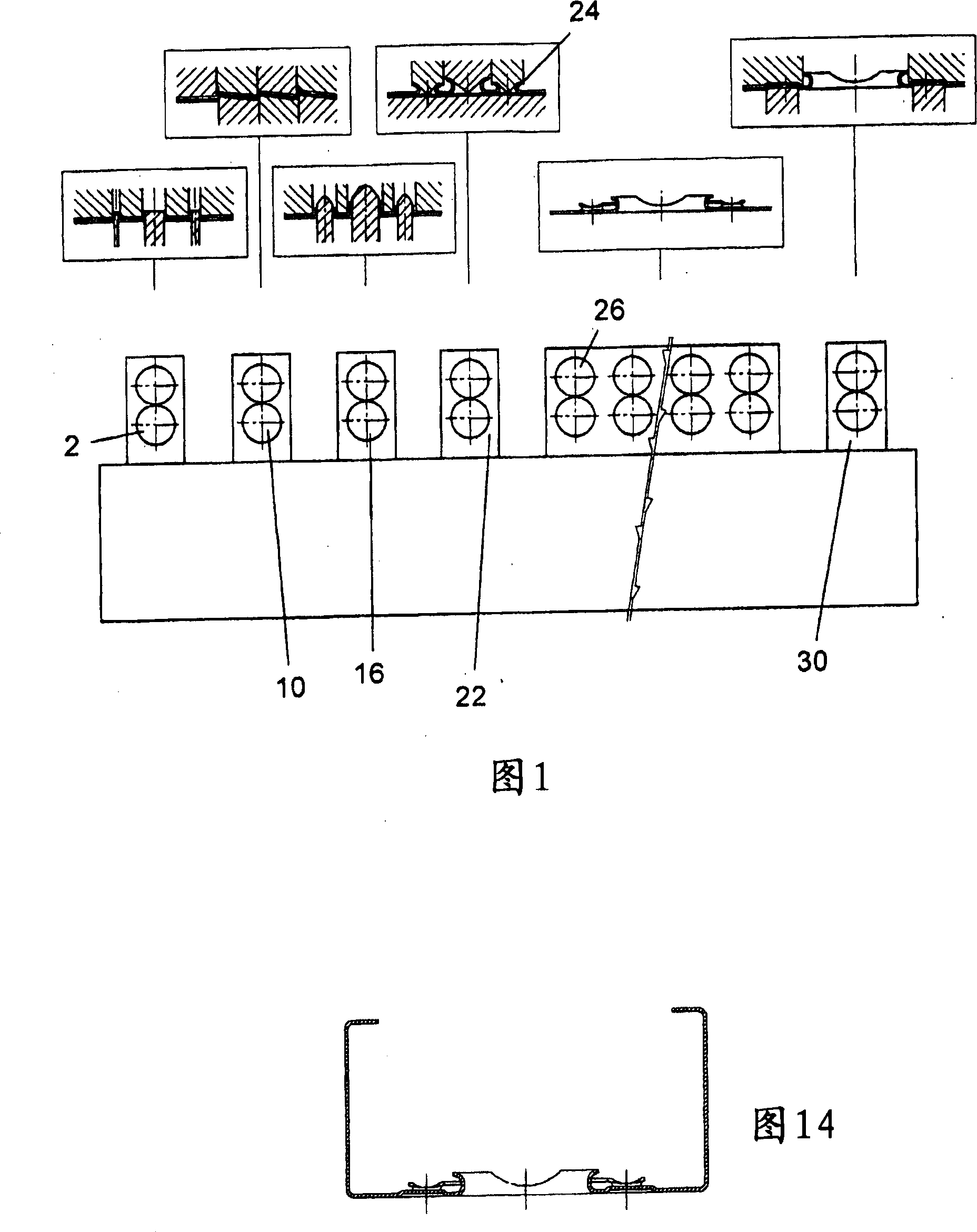

[0024] As can be seen from the accompanying drawings, with the method according to the invention, the unrolled metal strip with a width smaller than that of the obtained profile is uncoiled from the reel, and after a possible straightening operation, the metal strip passes through:

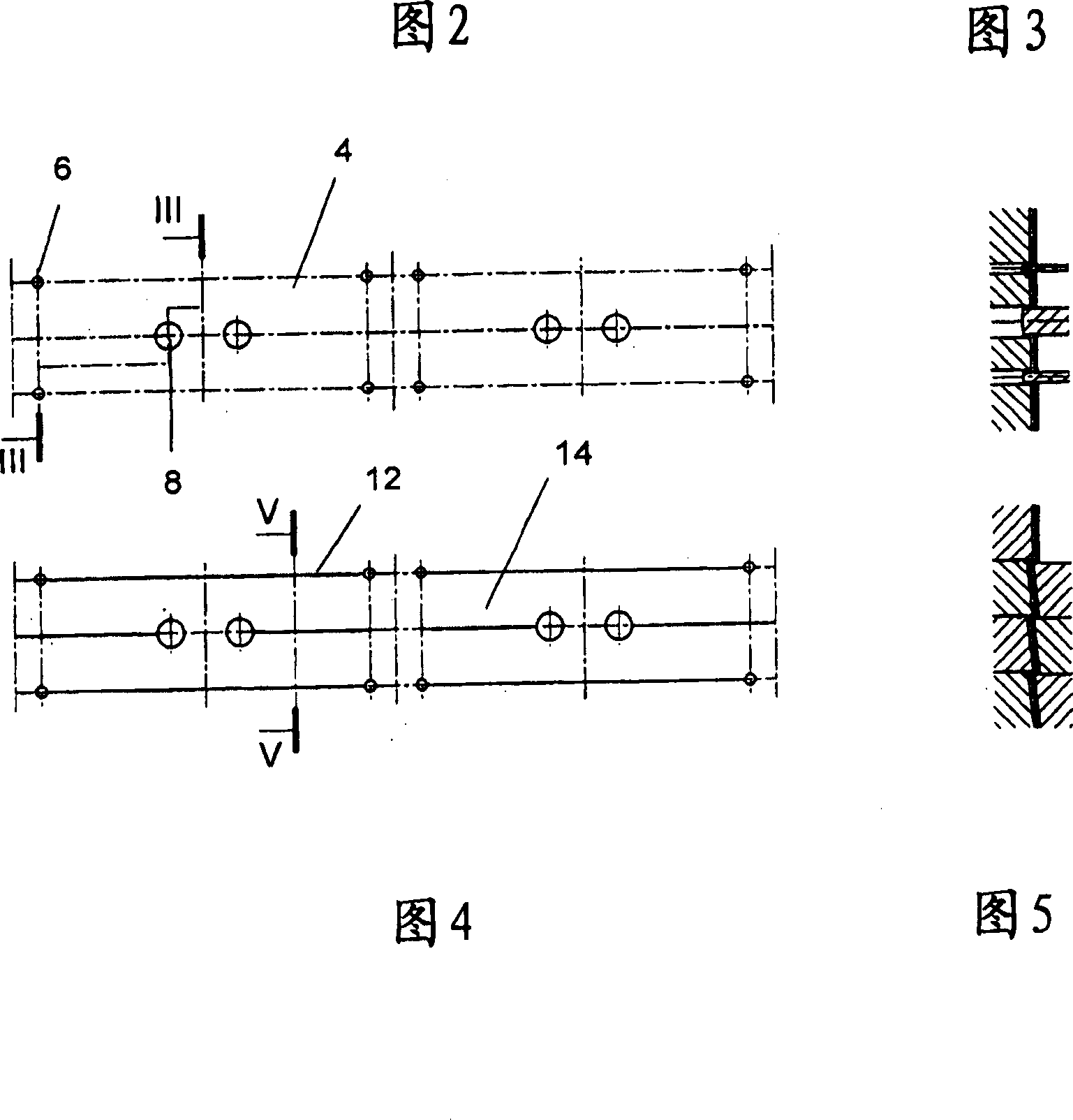

[0025] a pair of rolls 2 forming holes 6 and 8, respectively, in regions corresponding to the strip of metal sheet 4 to be slit;

[0026] a pair of slitting rolls 10 which form a plurality of longitudinal slits 12, 14 of different lengths arranged in parallel rows in the strip;

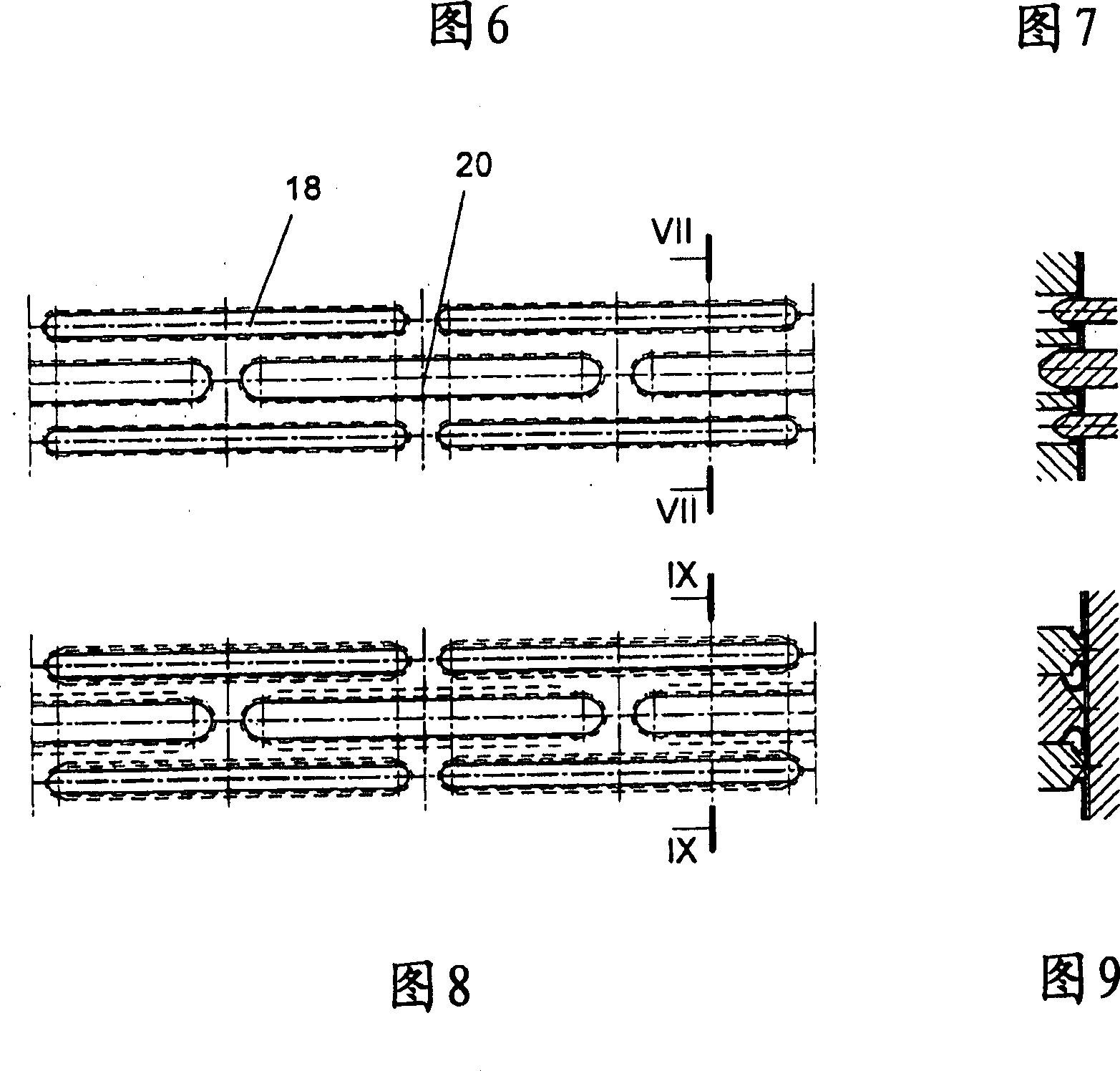

[0027] a pair of bending rolls 16 which form longitudinal oblong holes 18, 20 in the previously formed cuts 12, 14, wherein the edges of the oblong holes are bent towards the inside of the sheet metal strip;

[0028] A pair of deep drawing rolls 22, the punches of which are shaped to bend the curved edges of the oblong holes to obtain a rounded standing edge on each of said holes, the tangent of the free edge of which is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap