Synthetic resin window container, preform and preform injection molding device

A synthetic resin and preform technology, applied in containers, rigid containers, packaging, etc., can solve the problems of overflowing contents, inability to use with peace of mind, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

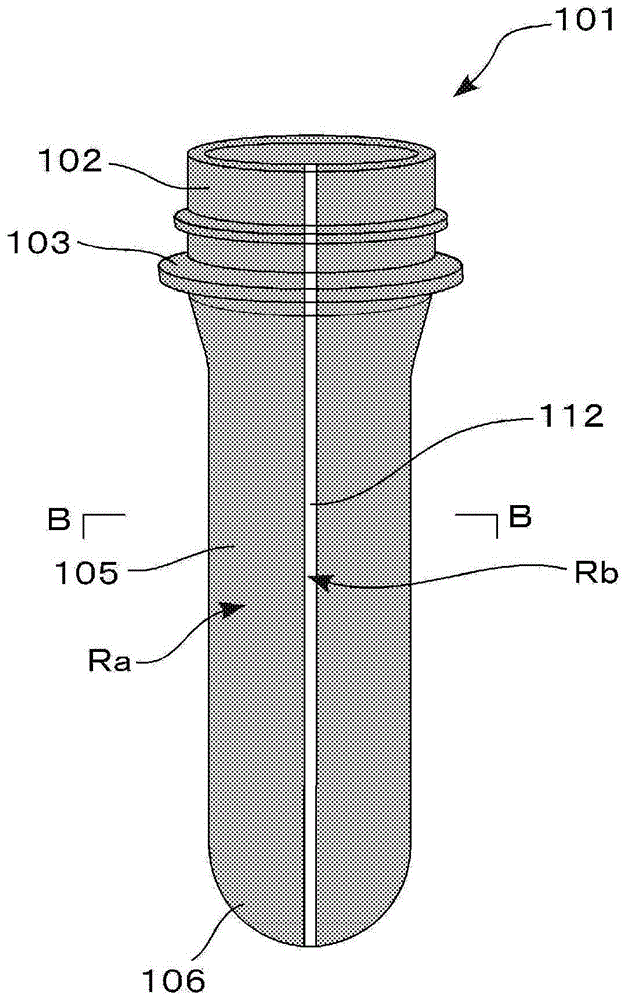

[0076]Hereinafter, a synthetic resin window container formed by biaxial stretch blow molding, a preform, and an injection molding apparatus according to the present invention will be described along with examples and with reference to the drawings.

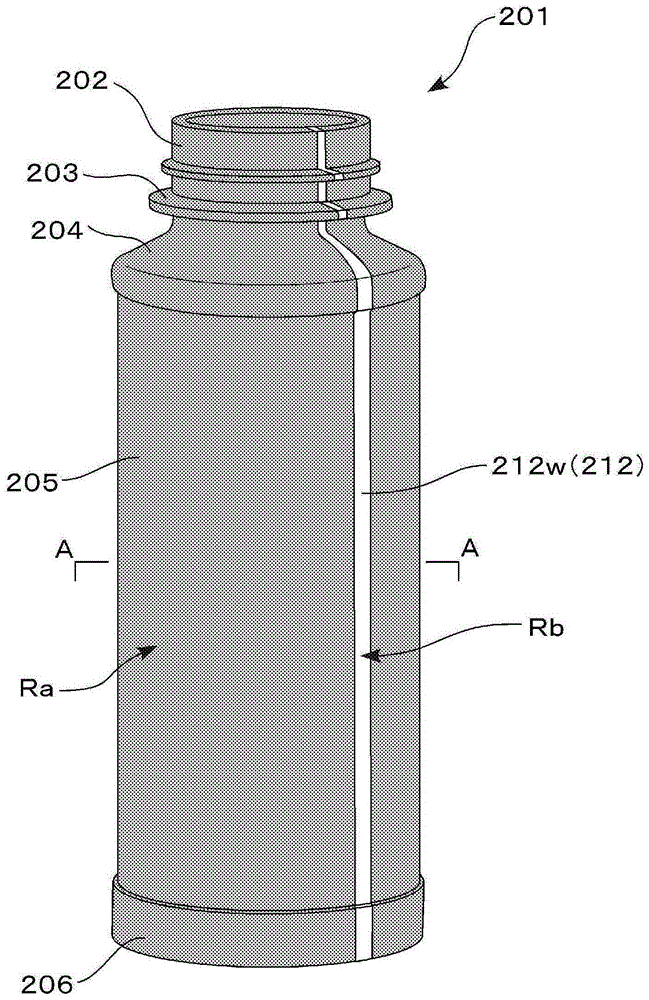

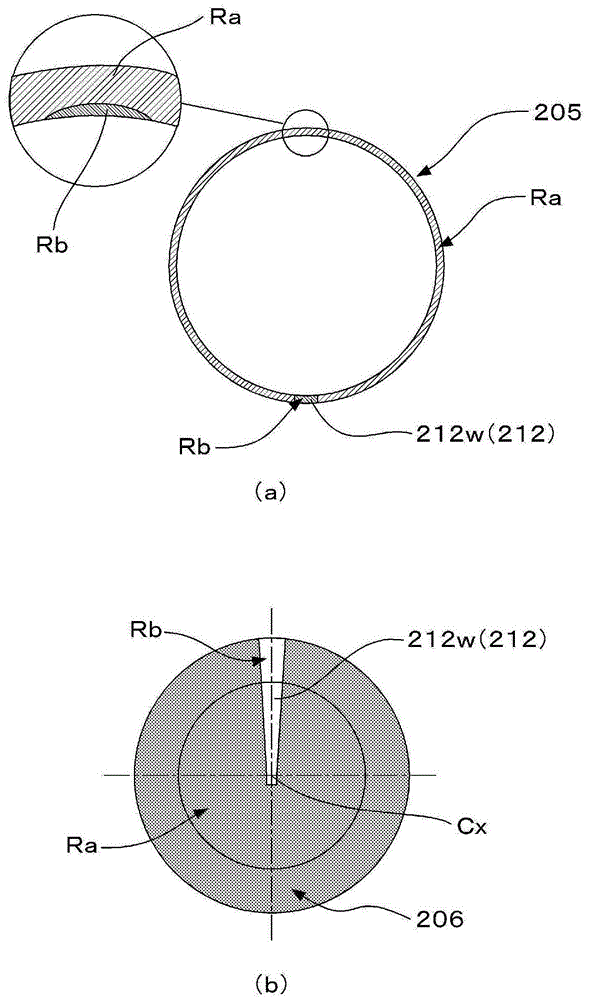

[0077] figure 1 and figure 2 One embodiment of the windowed container of the present invention is shown, figure 1 is the overall stereogram, figure 2 (a) is along figure 1 The plan view shown in the A-A line, figure 2 (b) is a bottom view.

[0078] This container 201 is a PET resin bottle made of biaxial stretch blow molding, and has a mouthpiece 202, a tapered shoulder 204, a cylindrical trunk 205, and a bottom 206. Around the mouthpiece 202, The ring is provided with a neck ring 203, and the diameter of the torso 205 is 55mm and the overall height is 190mm.

[0079] This container 201 is composed of A resin Ra obtained by coloring PET resin to be white and opaque, and B resin Rb which is an uncolored PET resin. In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com