Adhesive sheet and release member

一种剥离材料、粘合片的技术,应用在剥离材料,粘合片材用剥离材料,带有剥离材料的粘合片材领域,能够解决不实施轧纹加工等问题,达到平滑性优异、良好外观性、良好外观的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

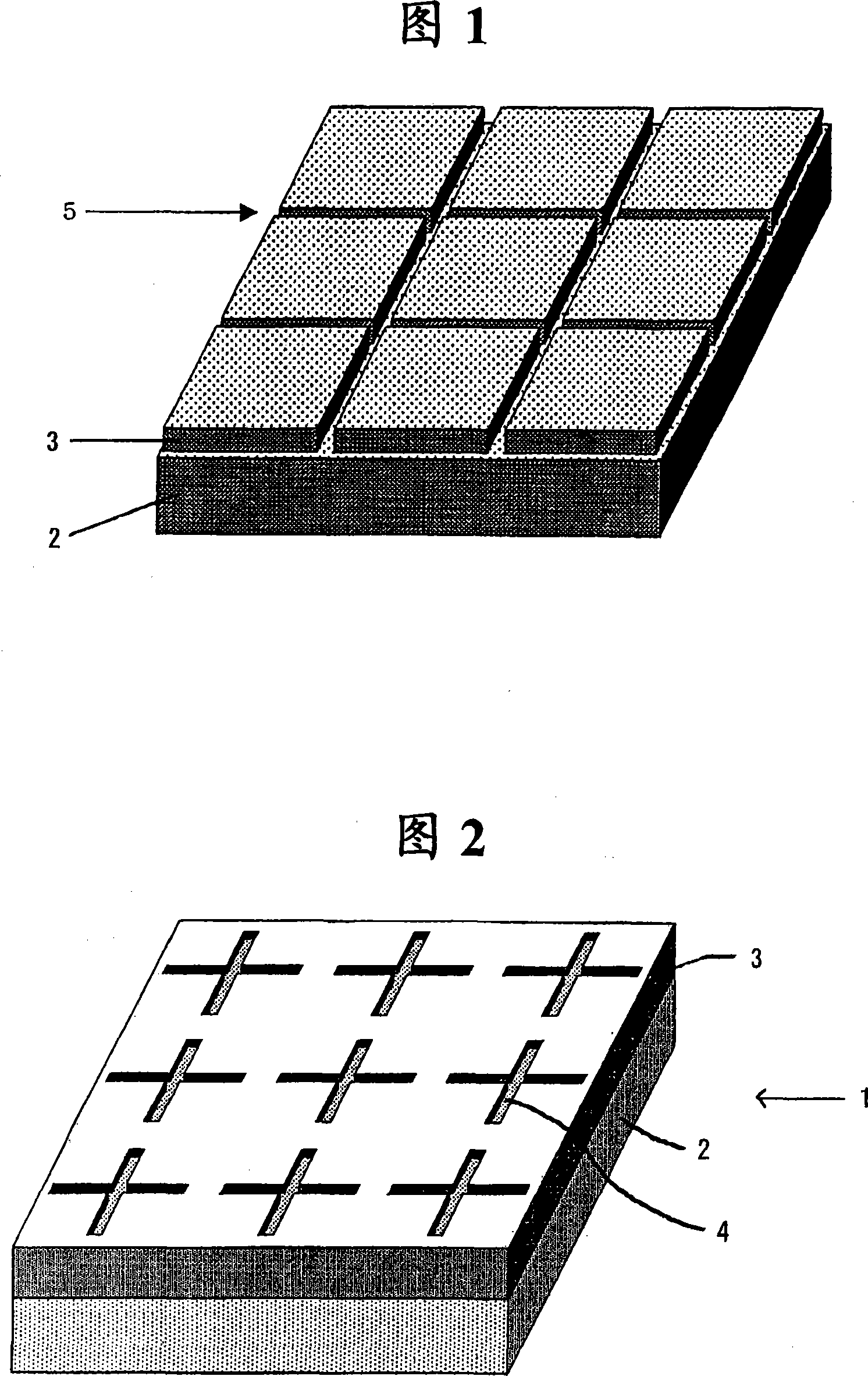

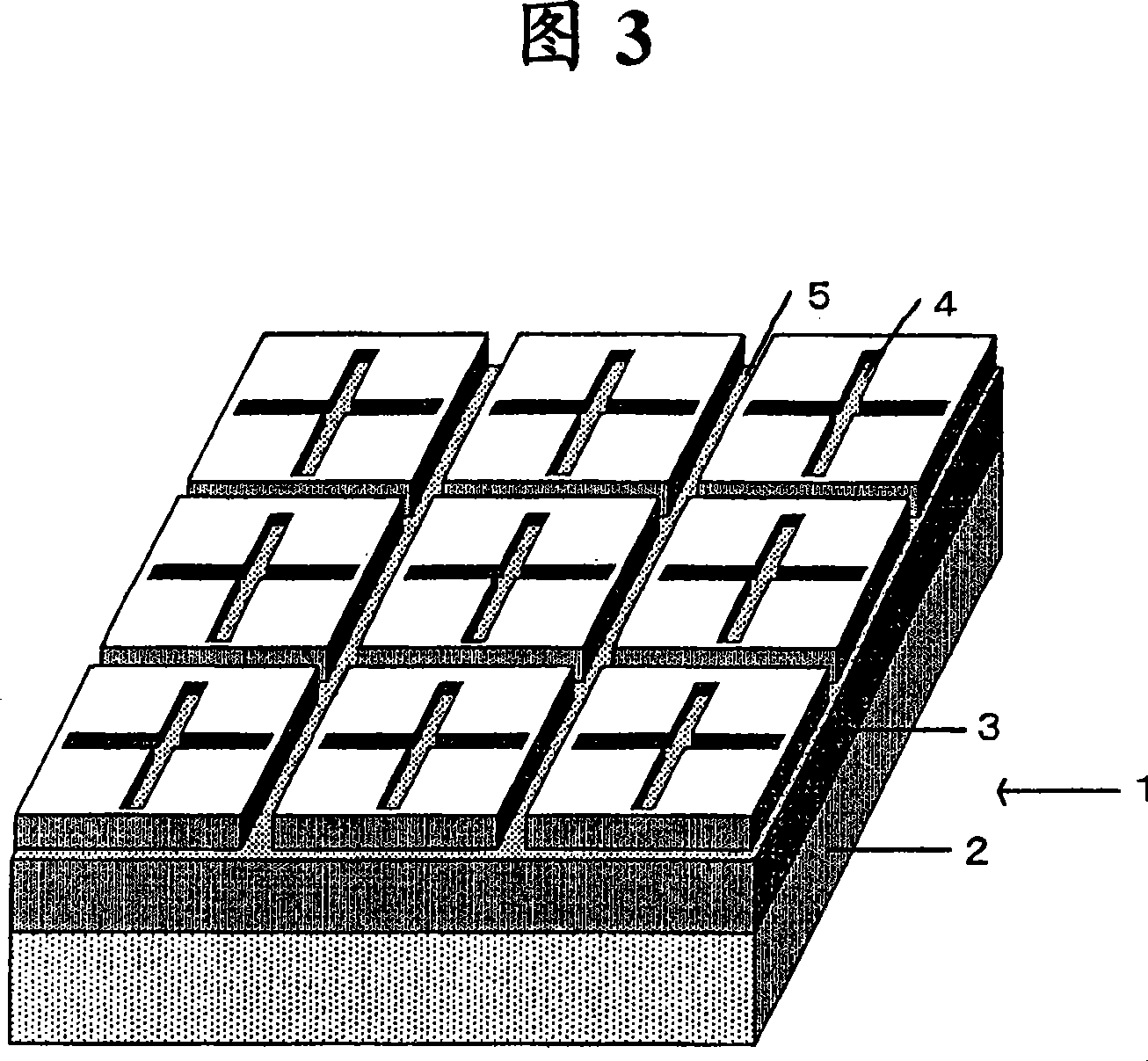

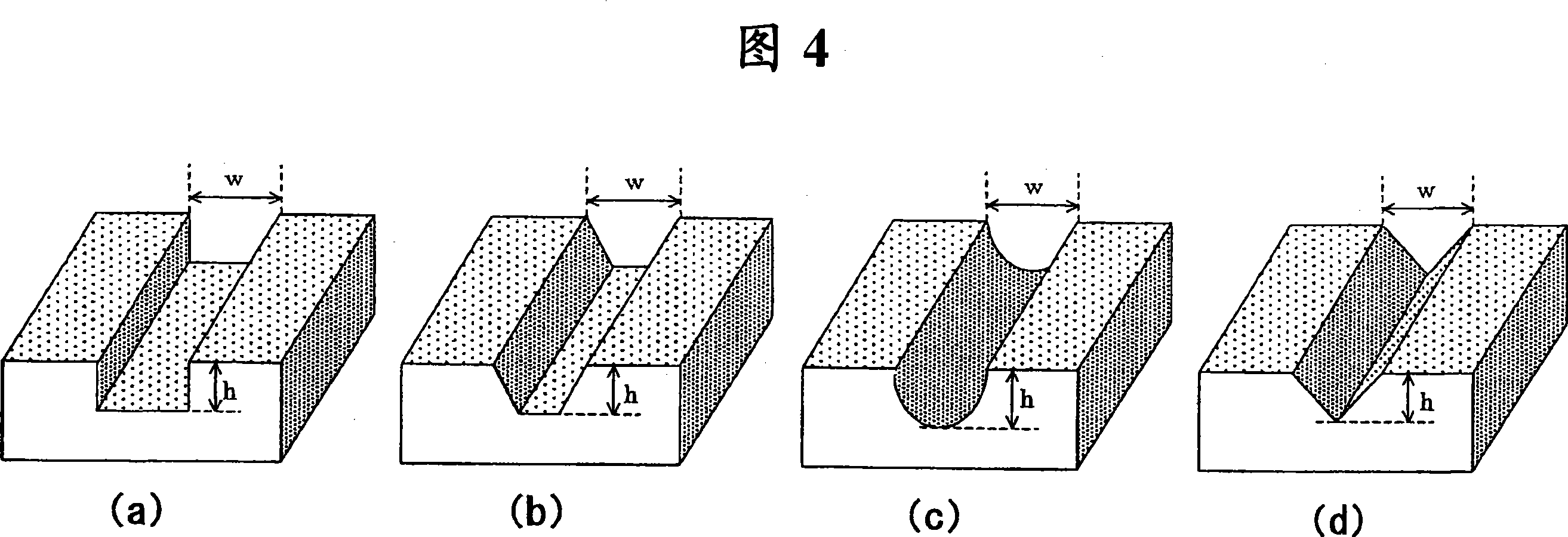

[0129] By pressing the concave embossed pressing plate shown in FIG. 2 against the release paper at 140° C. for 20 seconds, the embossed shape is transferred to the release paper to obtain a release material 1 having a convex surface shape, The die embossed pressing plate is spaced at 200 μm intervals (density: every 1 cm 2 2.5×10 3 1) engraved with a cross-shaped groove 4 that does not reach the side (the cross-section is U-shaped with a width of 20 μm and a depth of 10 μm, and the vertical and horizontal lengths of the cross are 100 μm).

[0130] Next, an acrylic adhesive and a hardener were mixed together with toluene and ethyl acetate as a solvent in a ratio of 1000:6:100:100 (weight ratio), and stirred well at room temperature for 2 minutes. This mixture was applied on the release material 1 and dried at 100° C. for 2 minutes to obtain an adhesive layer with a thickness of 30 μm. Next, an adhesive sheet A with a release material was obtained by laminating a PVC resin fi...

Embodiment 2

[0133] By pressing the concave embossed pressing plate shown in FIG. 5 against the release paper at 140° C. for 20 seconds, the embossed shape is transferred to the release paper to obtain a release material 2 having a convex surface shape, The die embossed pressing plate is spaced at 400μm intervals (density: every 1cm 2 7.2×10 2 1) engraved with a hexagonal groove 4 that does not reach the side (the section is U-shaped with a width of 30 μm and a depth of 15 μm, and the length of one side of the hexagon is 116 μm). Using this release material, it carried out similarly to Example 1, and obtained the adhesive sheet B with a release material.

Embodiment 3

[0135] By pressing the concave embossed pressing plate shown in FIG. 2 against the release paper at 140° C. for 20 seconds, the embossed shape is transferred to the release paper to obtain a release material 3 having a convex surface shape, The die embossed pressing plate is spaced at 100 μm intervals (density: every 1 cm 2 1.0×10 4 1) engraved with a cross-shaped groove 4 that does not reach the side (the cross-section is U-shaped with a width of 20 μm and a depth of 10 μm, and the vertical and horizontal lengths of the cross are 50 μm). Using this release material, it carried out similarly to Example 1, and obtained the adhesive sheet C with a release material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear shrinkage | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com