Non-tachogenerator belt conveyer scale

A technology of speed measuring sensor and belt scale, which is applied in the direction of instruments, measuring devices, weighing, etc., can solve the problems of measurement distortion of belt scale and inaccurate signal transmission of speed sensor, etc., and achieve the goals of reducing failure rate, convenient use and maintenance, and accurate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

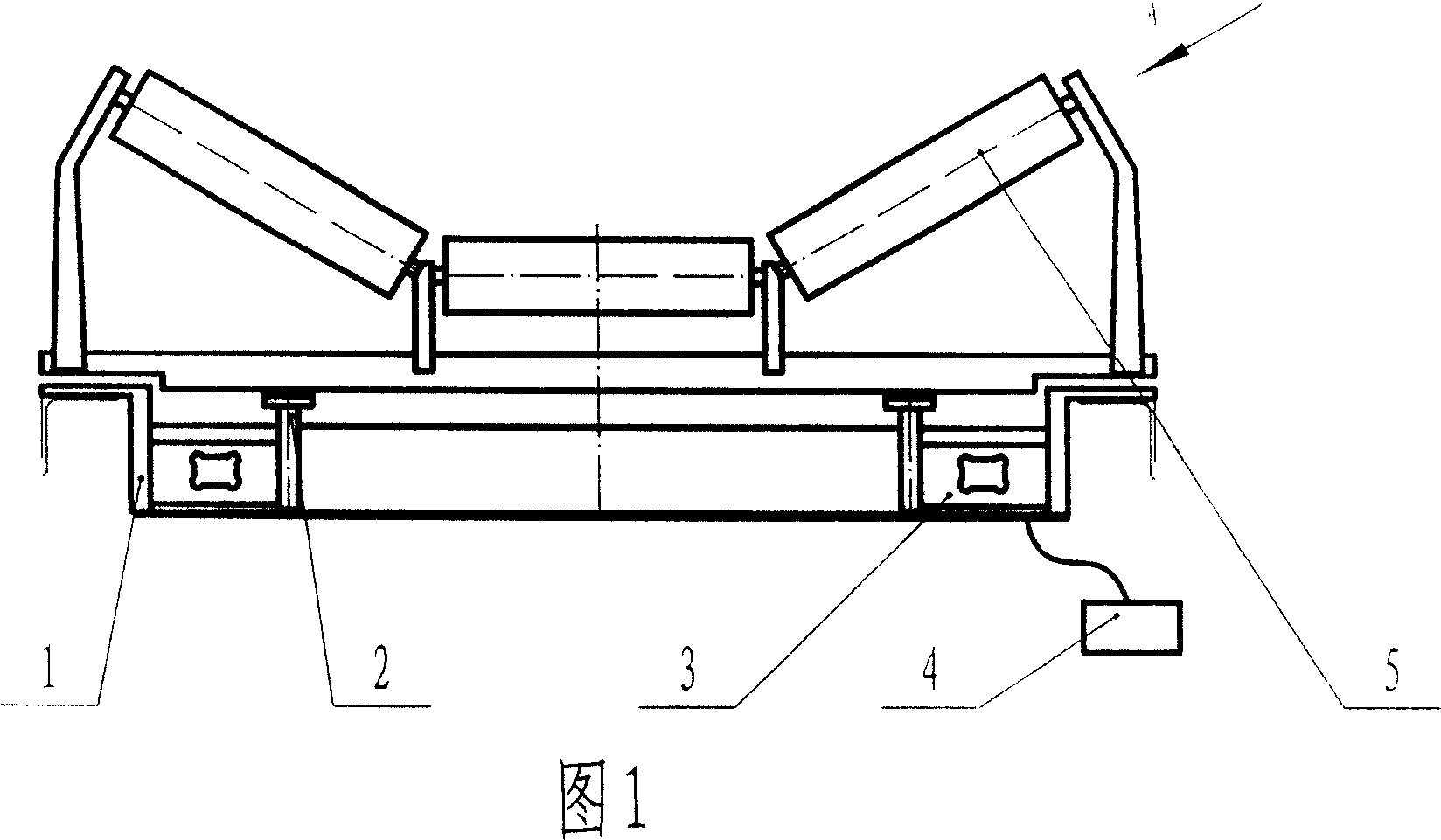

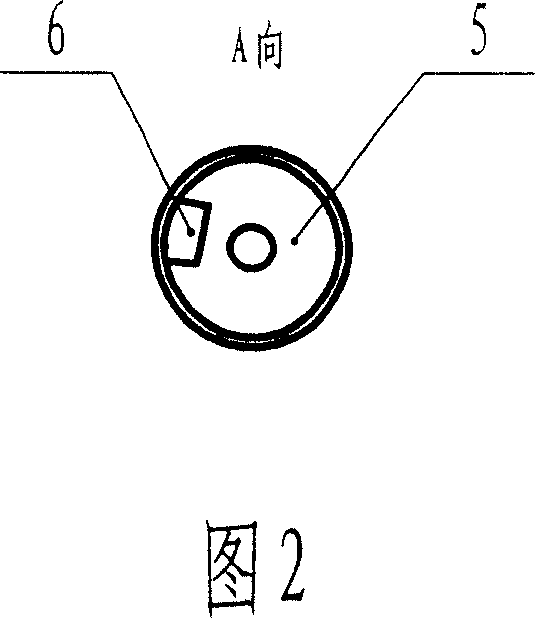

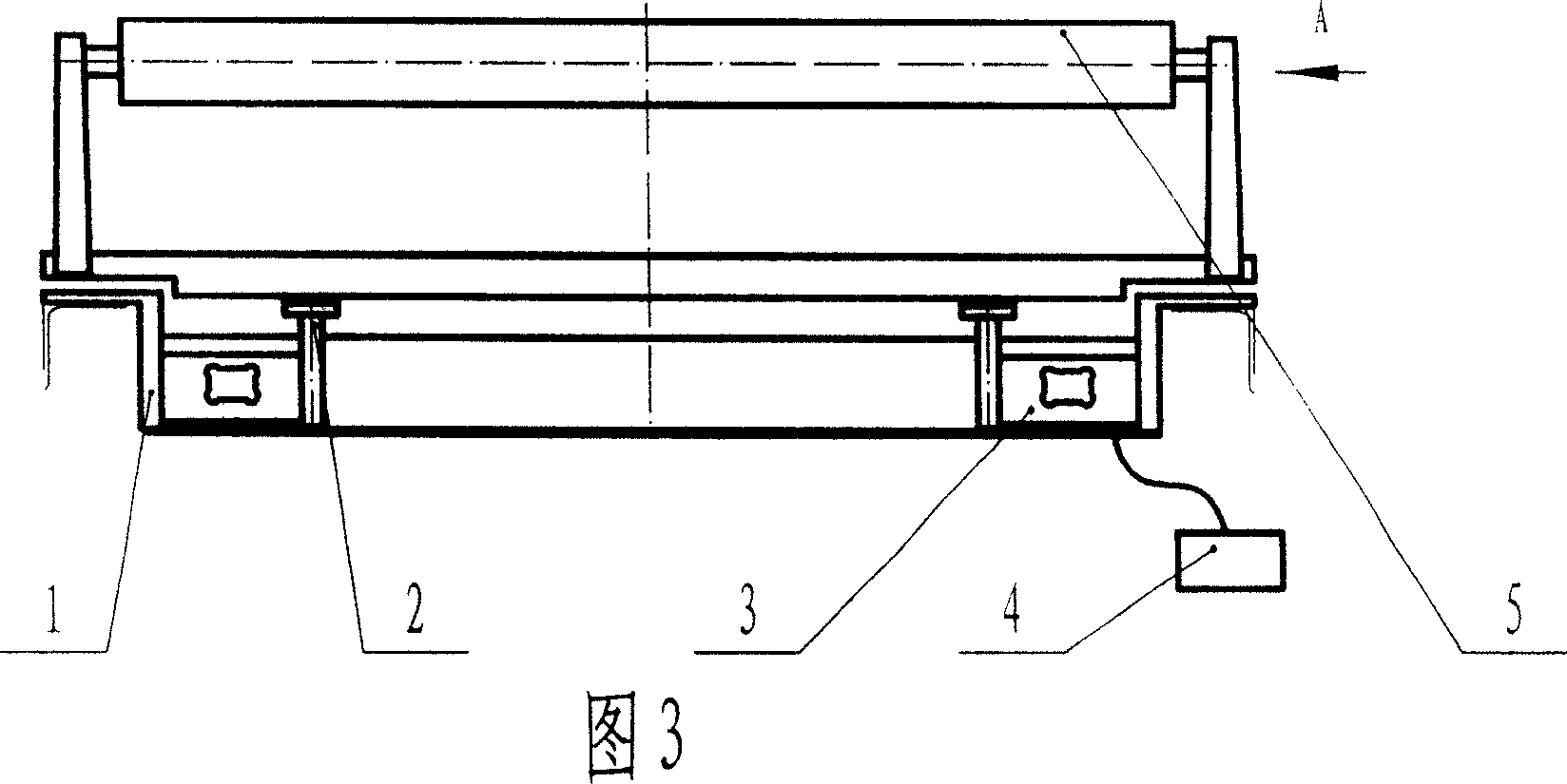

[0011] Embodiment 1: A belt scale without a speed measuring sensor, including a scale body 1, a weighing frame 2, a sensor 3, a secondary instrument 4, and a weighing idler 5. An eccentric block 6 is arranged inside the cavity of the weighing idler 5. The eccentric weight 6 and the weighing idler 5 are connected by bolts. The length of the eccentric block 6 is equal to the length of the weighing idler roller 5 . The weight of the material on the belt transmits the weight signal to the secondary instrument 4 through the weighing idler 5 and the weighing frame 2. At the same time, because the cavity of the weighing idler 5 is provided with an eccentric block 6, the idler 5 is eccentric. When rotating, the sensor 3 will receive a regular sine wave weighing signal, and the secondary instrument can calculate the speed of the belt by counting, and then obtain the material flow of the belt scale.

Embodiment 2

[0012] Embodiment 2: The connection between the weighing idler 5 and the eccentric block 6 of the present invention is a plug connection, so that the eccentric block 6 of different weight and shape can be conveniently replaced according to different belt scale specifications and material flow.

Embodiment 3

[0013] Embodiment 3: The connection between the weighing idler 5 and the eccentric block 6 of the present invention is welded connection,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com