Variable density drilling mud

A technology for drilling mud and density, which is applied in the direction of earthwork drilling, drilling composition, wellbore/well components, etc., and can solve the problem that the number of casing strings cannot be reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] [025] In the following detailed description and examples, the invention will be illustrated in conjunction with preferred embodiments. However, the extents described below are for specific embodiments or uses of the invention and are illustrative only. Therefore, the invention is not limited to the specific examples hereinafter, but on the contrary, the invention includes all alternatives, modifications and equivalents falling within the true scope of the appended claims.

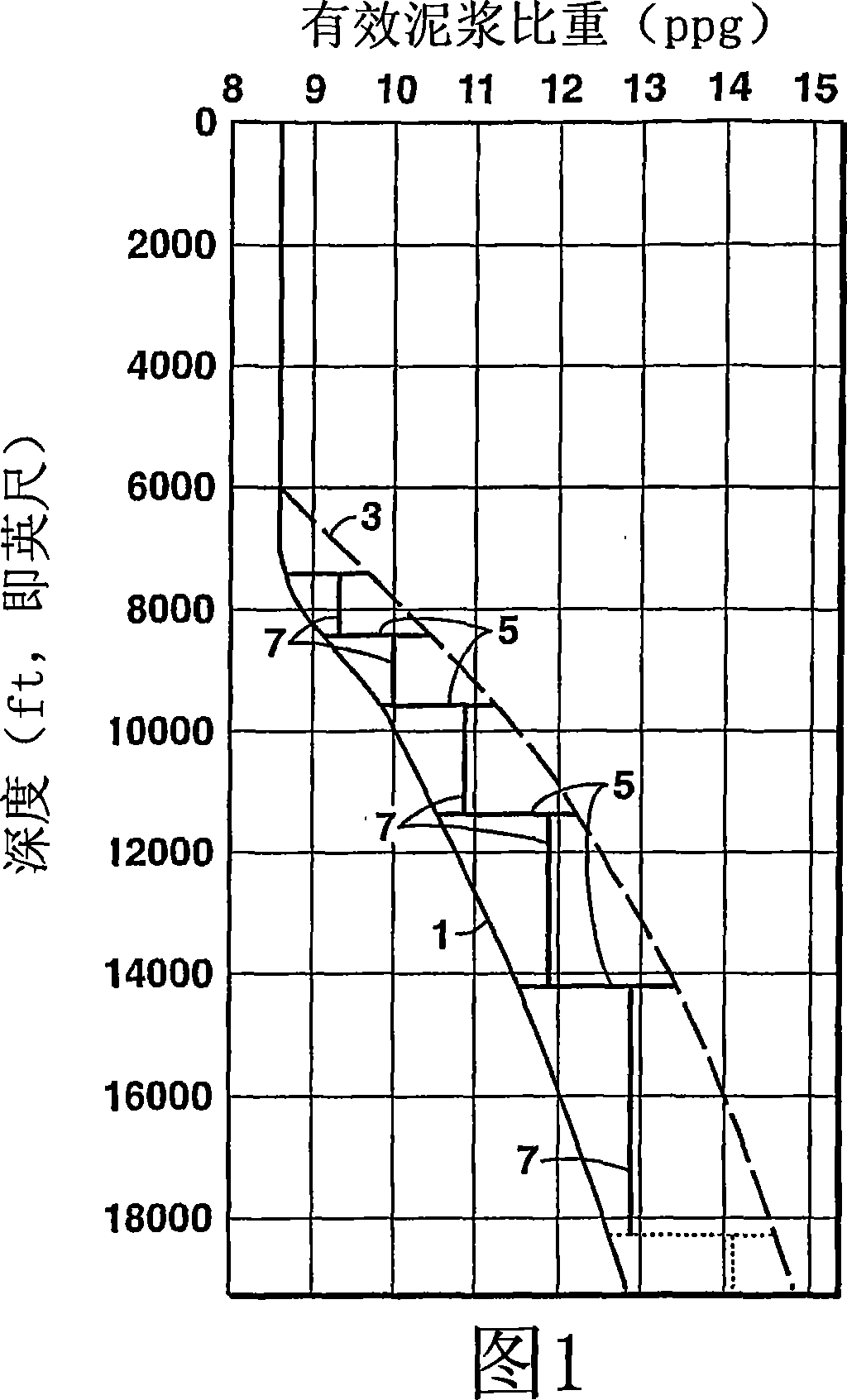

[0027] [026] Figure 1 illustrates a typical pore pressure gradient curve 1 and a fracture pressure gradient curve 3 with depictions of conventional casing setpoints 5. For a given casing set point, the mud specific gravity 7 is set so that it is higher than the pore pressure gradient curve 1 but lower than the fracture pressure gradient curve 3. Casing set point 5 allows for an increased open hole minimum fracture pressure gradient so that higher mud gravities can be used in the wellbore.

[0028][...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com