Micro-optic reflecting component

A technology of optical reflection and components, applied in the direction of optical components, optics, installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

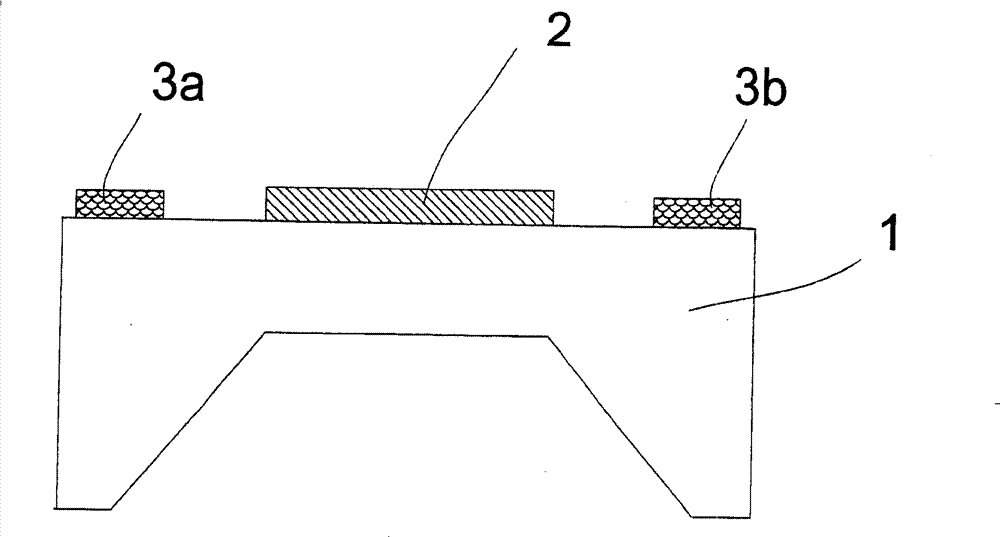

[0036] figure 1 A cross-section of a component fabricated using microsystems techniques is given. A substrate 1 consisting of silicon is machined from the back as a diaphragm. Bimorph properties can be achieved by the deposition of a reflective layer 2 . The contact points 3a, 3b are arranged on both sides. When a voltage is applied between these contact points 3a, 3b, current flows through the substrate 1 via the contact points and heats the membrane. The curvature of the membrane is changed by the resulting temperature increase.

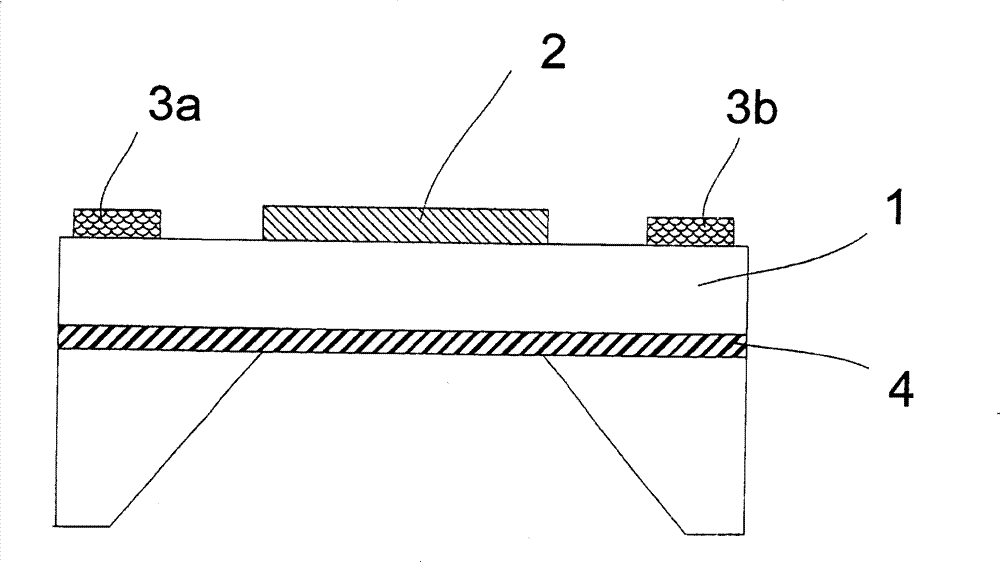

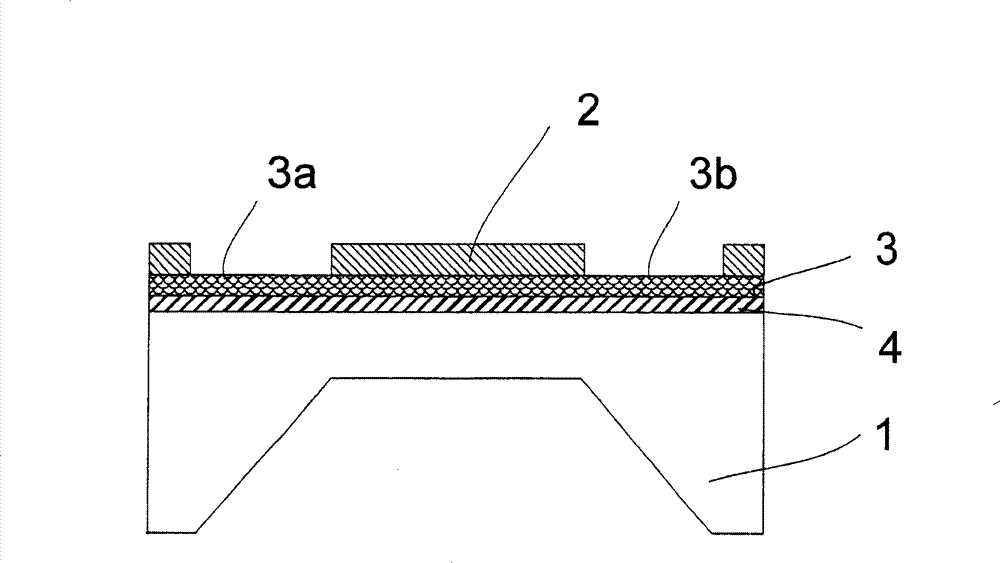

[0037] figure 2 A similar principle is given, but here the substrates 1 are separated by an electrically and thermally insulating intermediate layer 4 . This intermediate layer 4 serves on the one hand as an corrosion stop during the production of the component and on the other hand thereby reduces the heat conduction from the diaphragm to the separated substrate regions. Furthermore, the application of a third layer - in addition to substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com