Direct-type fuel cell and direct-type fuel cell system

一种燃料电池、直接的技术,应用在燃料电池、燃料电池助剂、燃料电池的零部件等方向,能够解决没有提出阴极、燃料量不足、放电性能减弱等问题,达到抑制燃料使用率的下降、抑制燃料使用率的降低、减少穿越现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

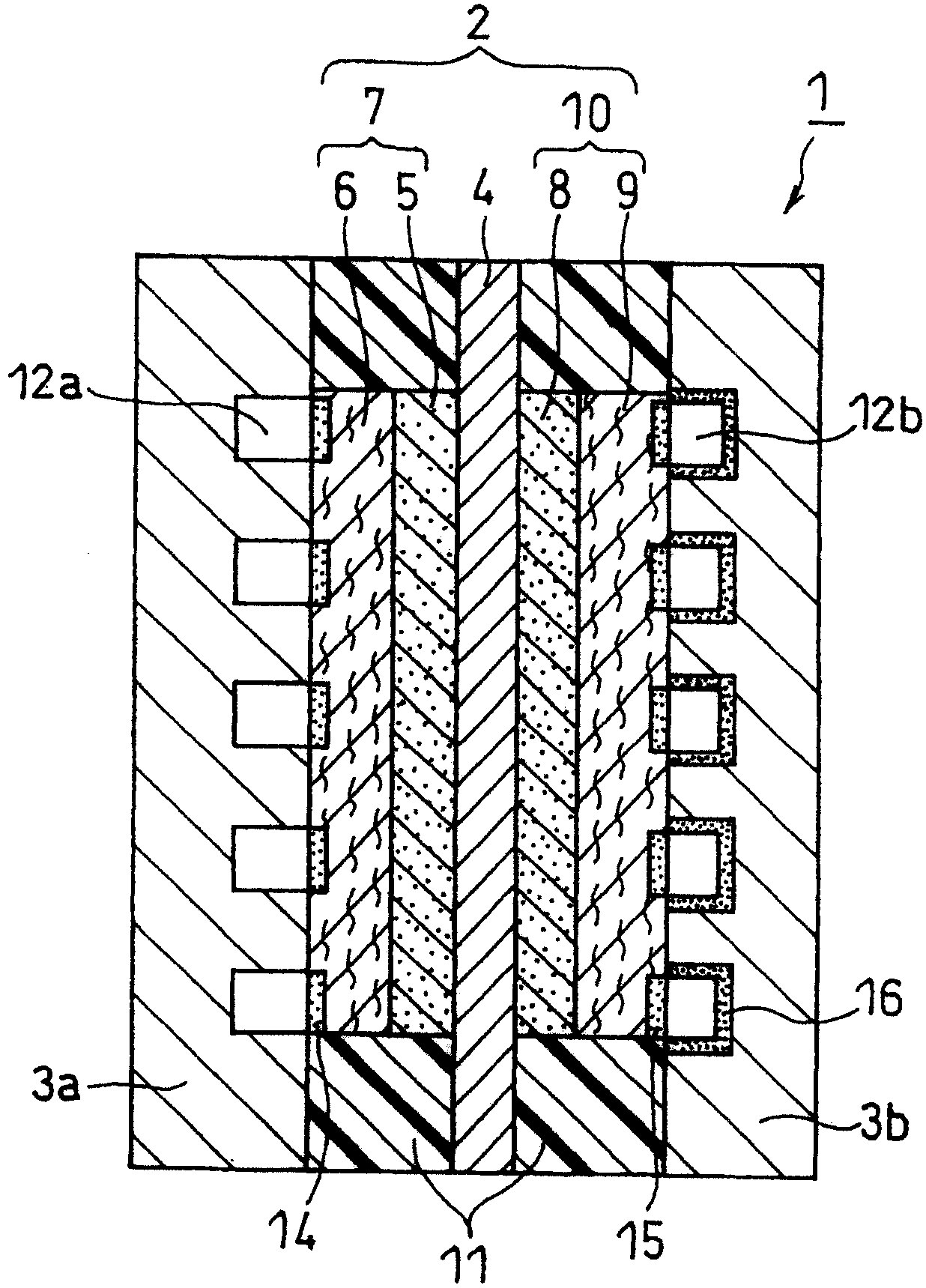

[0095] Prepare a figure 1 The fuel cell shown.

[0096] (i) Anode side catalyst layer

[0097] The anode-supported catalyst particles are prepared by loading 30 wt% of platinum particles and 30 wt% of ruthenium particles on conductive carbon black particles. The average particle size of platinum particles and ruthenium particles are both 3nm, while the average primary particle size of carbon black particles is 30nm (ketjen black EC, purchased from Mitsubishi Chemical Company).

[0098] The isopropanol aqueous solution in which anode-supported catalyst particles are dispersed and the polymer electrolyte in ethanol are mixed. The mixed solution was stirred in a ball mill to prepare an anode catalyst paste. The weight percentage of conductive carbon black particles and polymer electrolyte in the anode catalyst paste is 2:1. The electrolyte used was perfluorocarbon sulfonic acid ionomer (Flemion, purchased from Asahi Glass Co., Ltd.).

[0099] Use a medical scraper to apply the anode c...

Embodiment 2

[0111] When the diffusion surface layer 14 (PTFE / silicone resin layer) is formed on the anode side diffusion layer 6 substrate, the number of repetitions of spraying and air drying is changed, and the high temperature drying temperature is changed to 80°C for 60 minutes to make the diffusion surface The thickness of the layer 14 becomes about 100 μm. Except for these modifications, a fuel cell (cell B) was prepared in the same method as in Example 1.

Embodiment 3

[0113] Carbon paper (TGP-060, available from Toray Industries) with a thickness of 180 μm was used instead of TGP-H120 as the substrate of the anode-side diffusion layer 6. At the same time, when the diffusion surface layer 14 (PTFE / silicone resin layer) is formed on the substrate of the diffusion layer 6 on the anode side, the number of repetitions of spraying and air drying is changed, and the high-temperature drying temperature is changed to 70°C for 20 minutes, thereby The thickness of the diffusion surface layer 14 is changed to about 5 μm. Except for these modifications, a fuel cell (cell C) was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com