Electrical device, particularly relay socket, with spring clip and method of manufacture

A technology of relay sockets and electrical components, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of complex installation and operation, and achieve the effect of reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

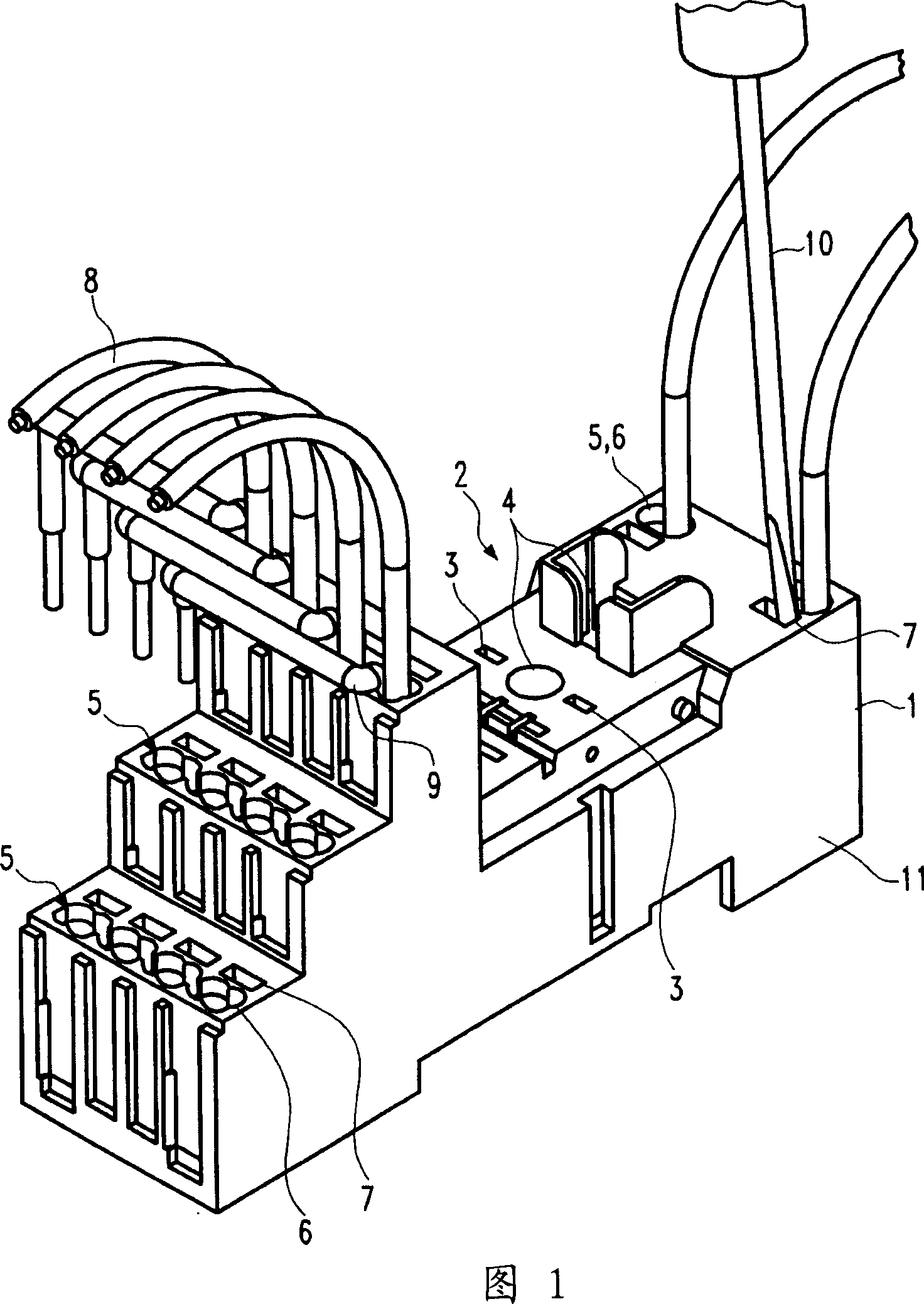

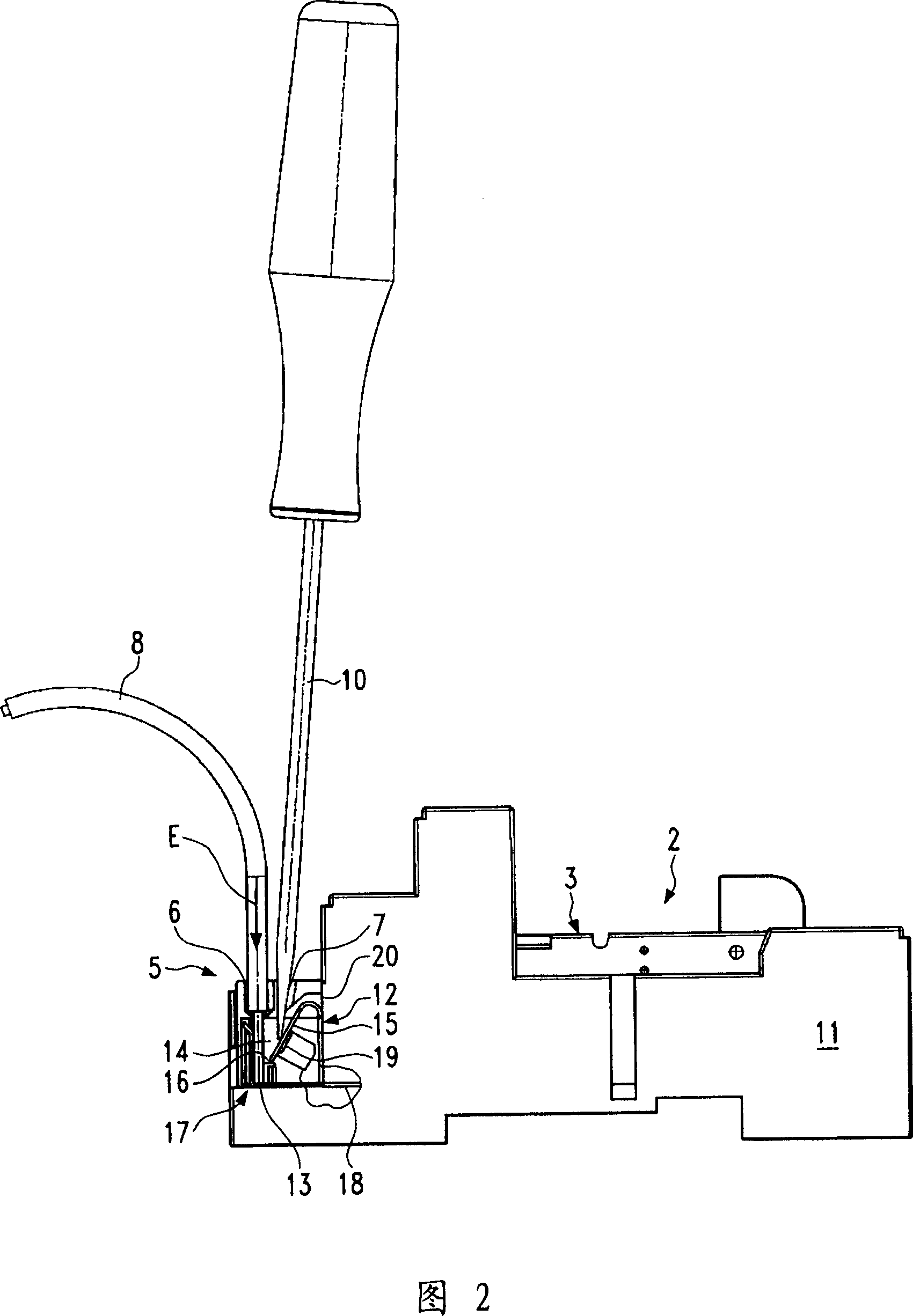

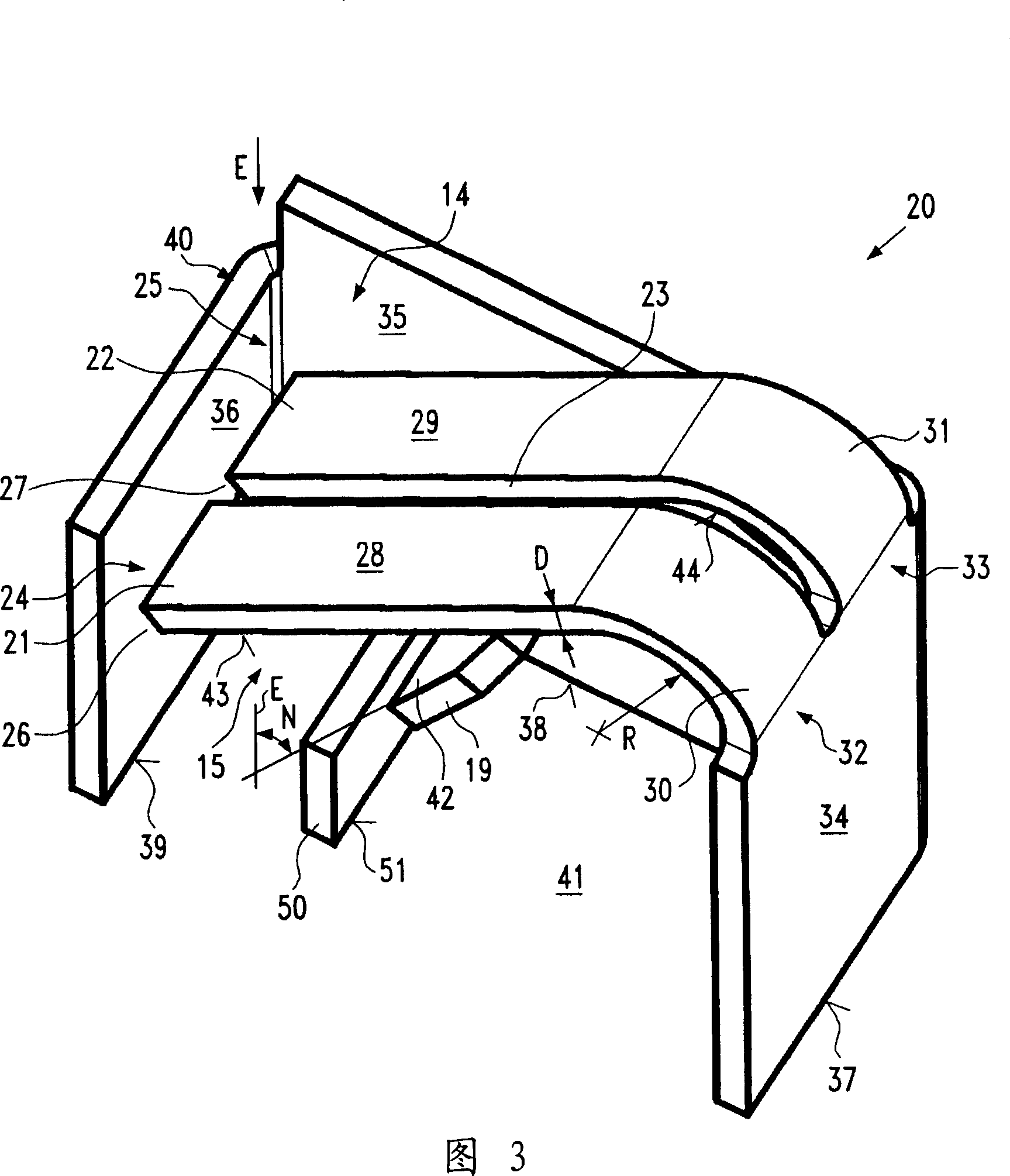

[0035] FIG. 1 shows a relay socket 1 as an electrical component to which the present invention is applied. The relay socket 1 receives a relay (not shown) in a receiving area 2 provided with plug contacts 3 for a relay plug (not shown) and for precise positioning of the relay (not shown) in the receiving area 2 The positioning device 4.

[0036] The relay socket 1 is provided with a plurality of terminals 5 connected to plug contacts 3 for relays (not shown) through conductor elements (not shown in FIG. 1 ). The terminals 5 are each provided with at least one insertion opening 6 and at least one actuation opening 7 .

[0037] At least one conductor 8 and / or at least one connection part 9 can be pushed into the insertion opening 6 . The inner contour of the insertion opening 6 corresponds to the outer contour of the connecting parts 9 or conductors 8 arranged adjacent to each other, with the result that these elements are individually supported and positioned by the walls of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com