Duty-cycle correction circuit and method for differential clocking

A differential correction, differential clock technology, applied in electrical components, converting continuous pulse trains into pulse train devices with required patterns, pulse technology, etc., can solve large-area, single-ended feedback circuits that are prone to noise, high power And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

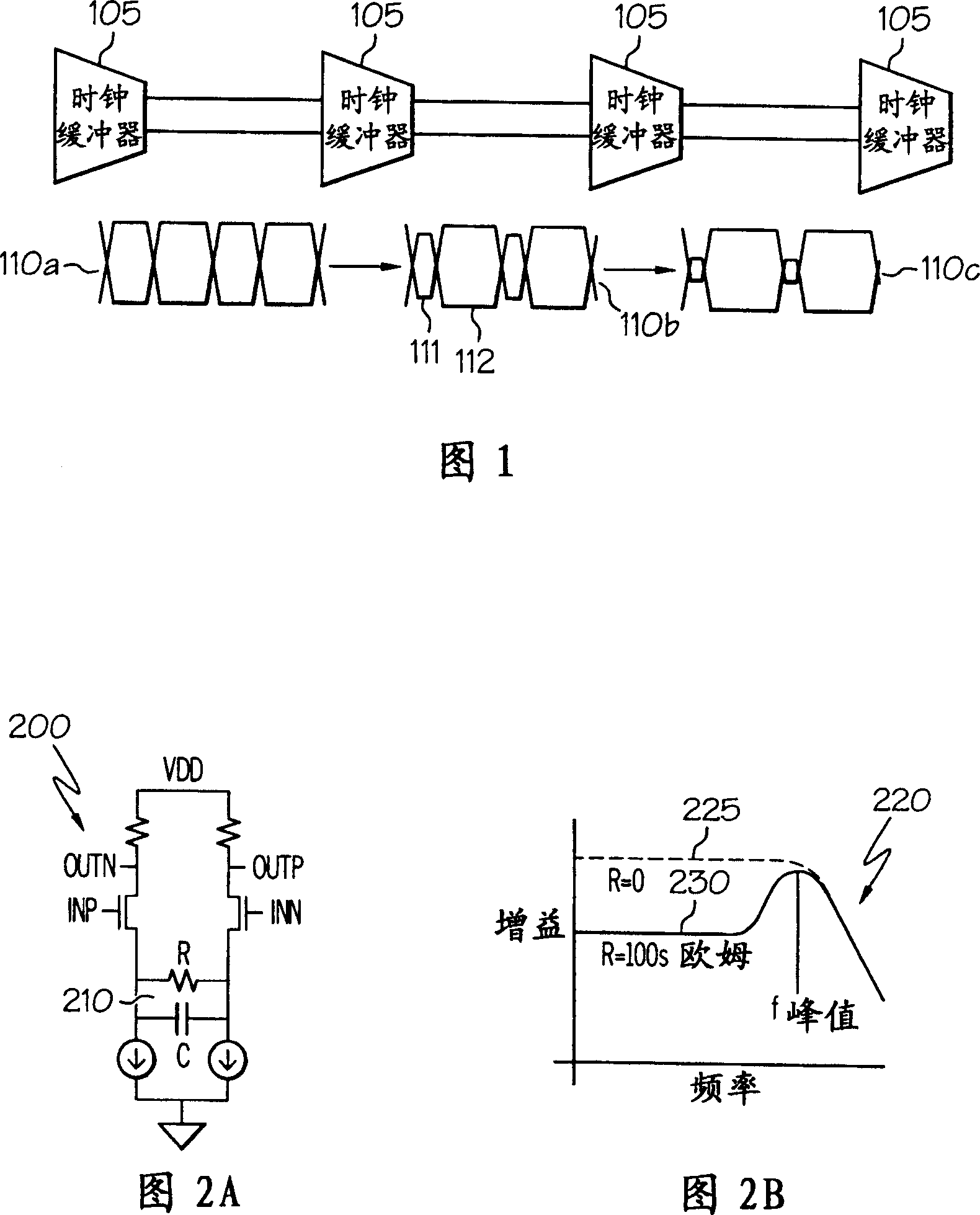

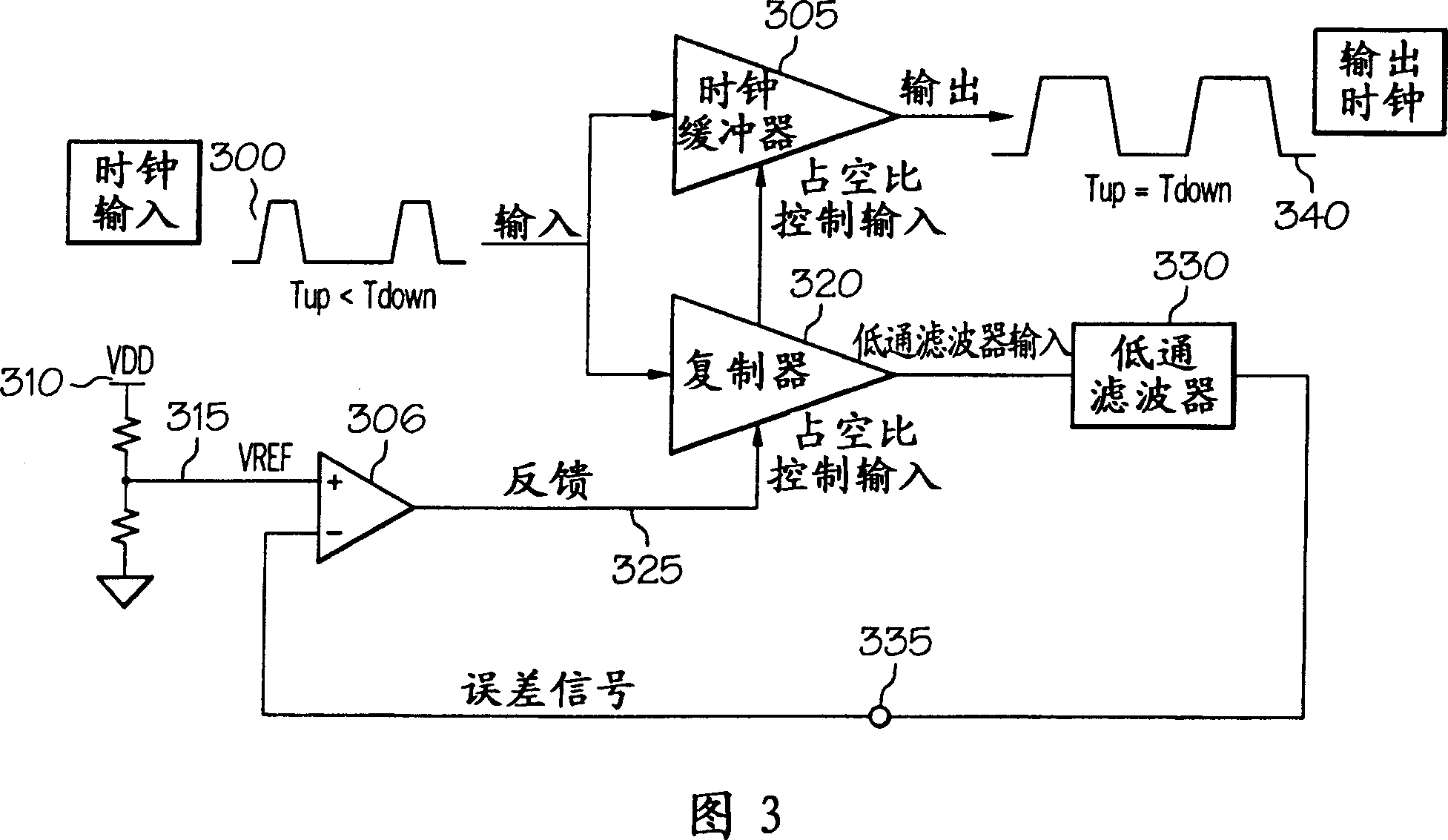

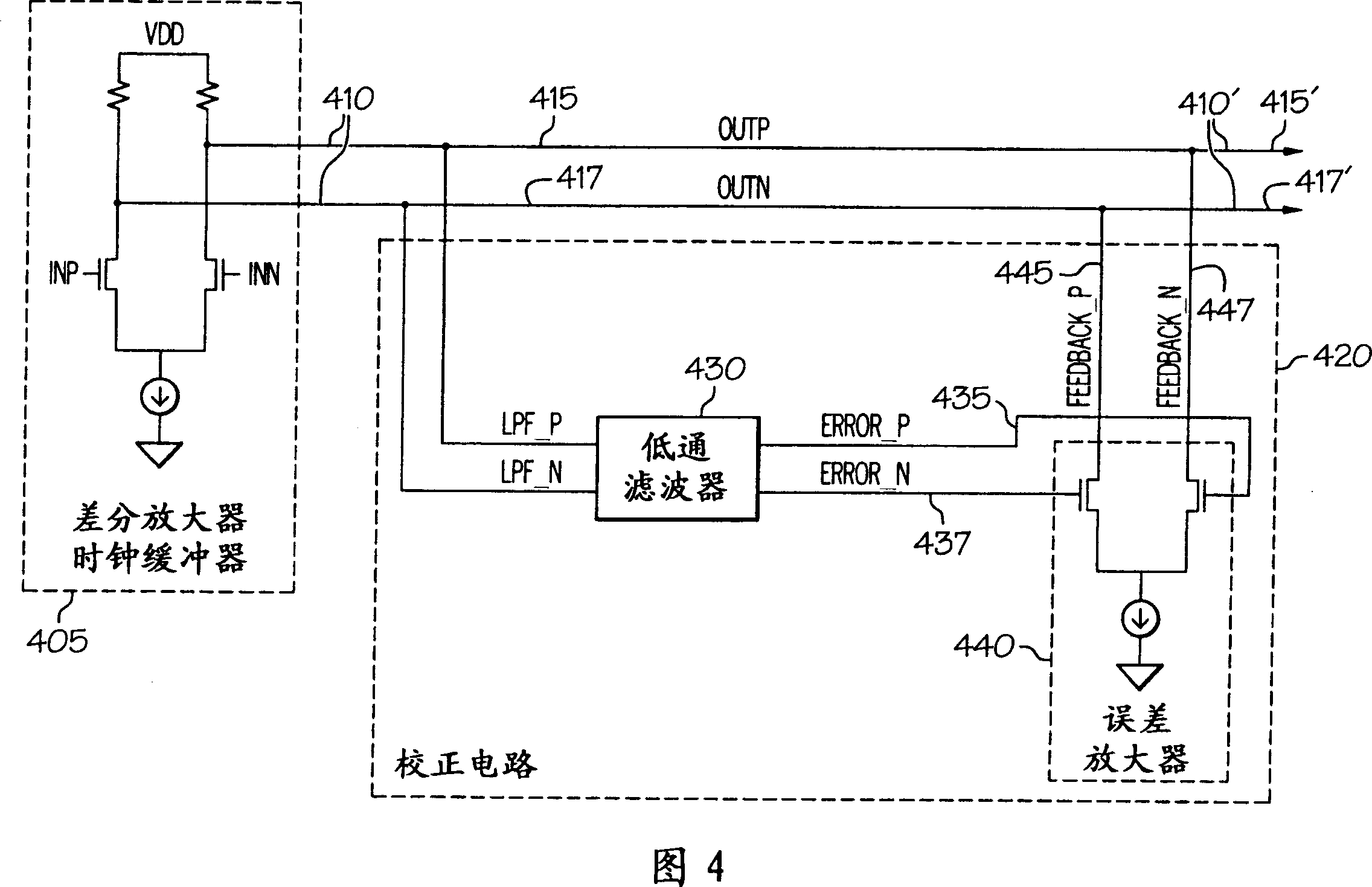

[0019] The present invention provides a circuit design and method for correcting duty cycle distortion of a differential clock signal propagating through a differential amplifier (or clock buffer). The circuit components employed include a differential amplifier, a low pass filter, and a correction current source combined into a simple two-stage amplifier circuit with a correction output dotted to the differential output of the differential buffer.

[0020] The correction circuit is connected to both the (differential) output pulses / signals from the differential amplifier. The correction circuit includes: a differential low pass filter which filters out the DC (direct current) component of each output pulse / signal of the differential output; and a differential error amplifier which compares the DC outputs from the low pass filter and generates a pair of The differential error adjusts the DC current. The differential error adjusting DC current is then fed back to each pulse of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com