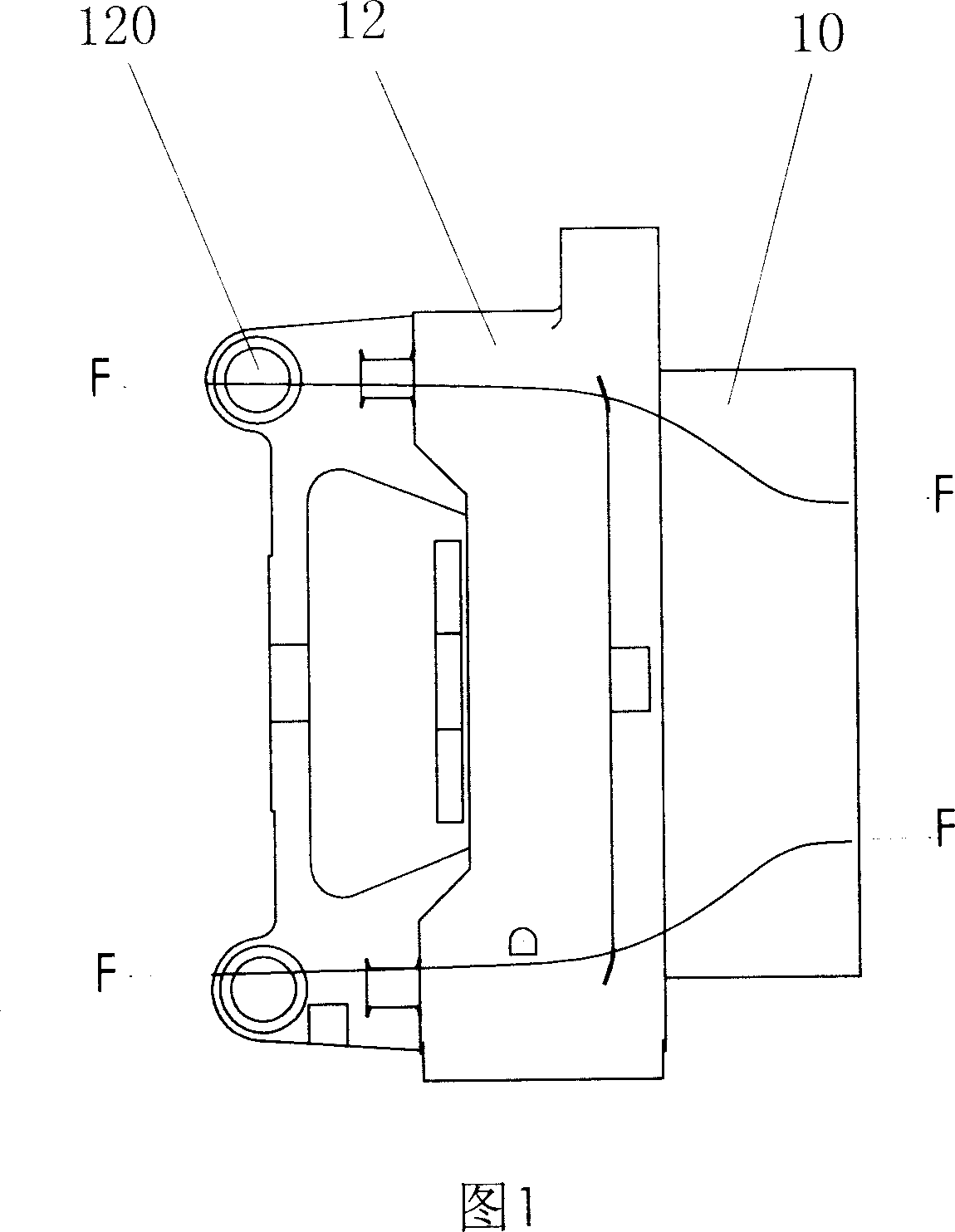

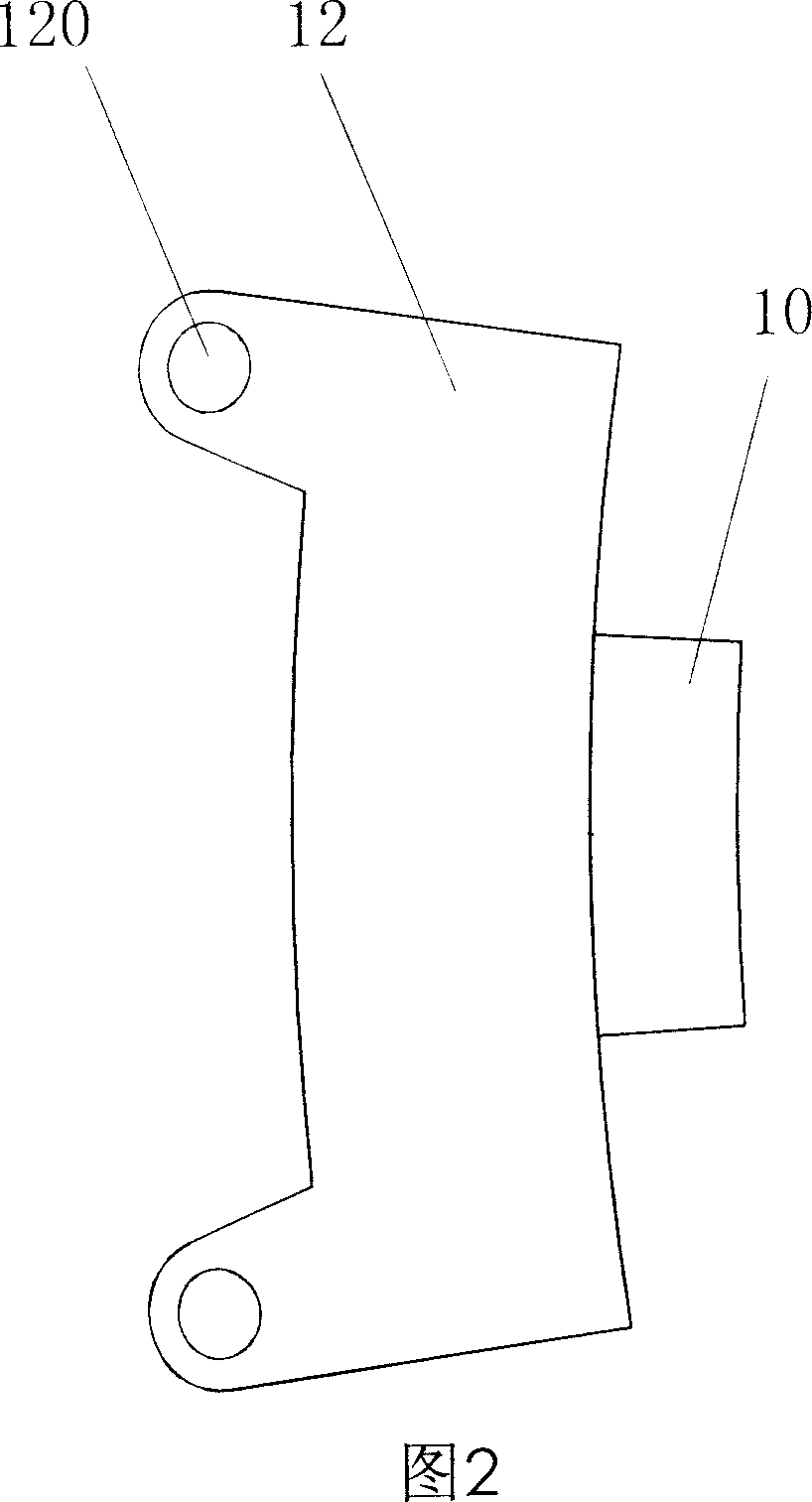

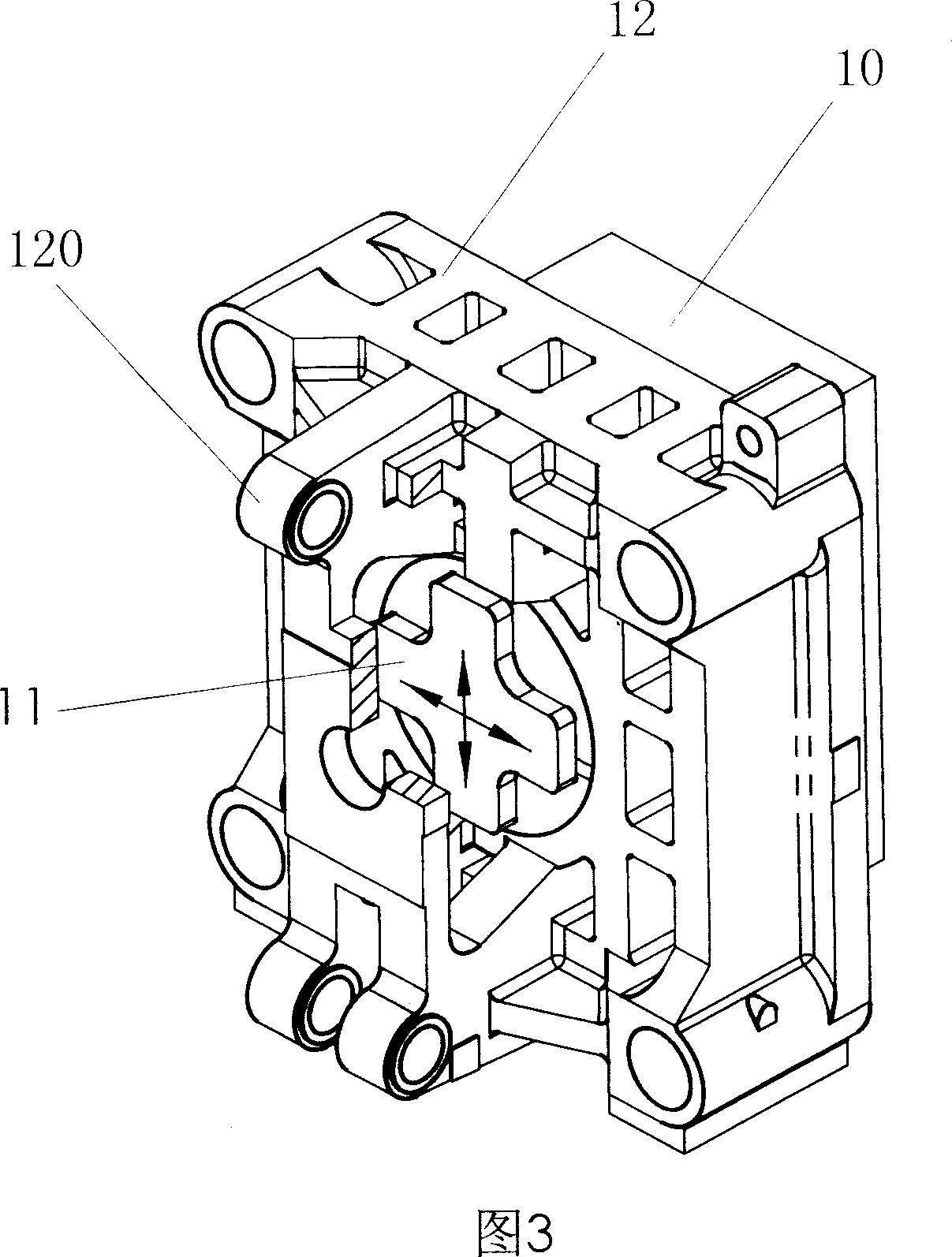

Separate moving templet structure of reaming type mould clamping mechanism

A moving formwork and separate technology, applied in the field of moving formwork, can solve the problems of ejector plate breakage, high clamping force, product flash phenomenon, etc., to achieve the effect of providing ejection position space, improving performance, and reducing mold deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] Referring to Fig. 4 to Fig. 7, the separated movable template structure of the hinged mold clamping mechanism is characterized in that it is provided with a front movable template 1 for installing the mold, a supporting block 2 and a rear movable template 3 connected to the hinge mechanism, and the supporting block 2 is arranged between the front moving template 1 and the rear moving template 3, and its two ends are offset against the front moving template 1 and the rear moving template 3 respectively. The front movable formwork 1, support block 2 and rear movable formwork 3 are integrally formed by casting or assembled from single parts.

[0021] There are four support blocks 2 in this embodiment, and the support blocks 2 are roughly evenly distributed along the center of the rear movable template 3 . The supporting block 2 is supported roughly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com