Antiswary bar with clamping band

A technology of stabilizer bars and clamps, applied in interconnection systems, suspensions, transportation and packaging, etc., can solve problems such as low efficiency, disconnection, and inability to achieve adjustable shrinkage, and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

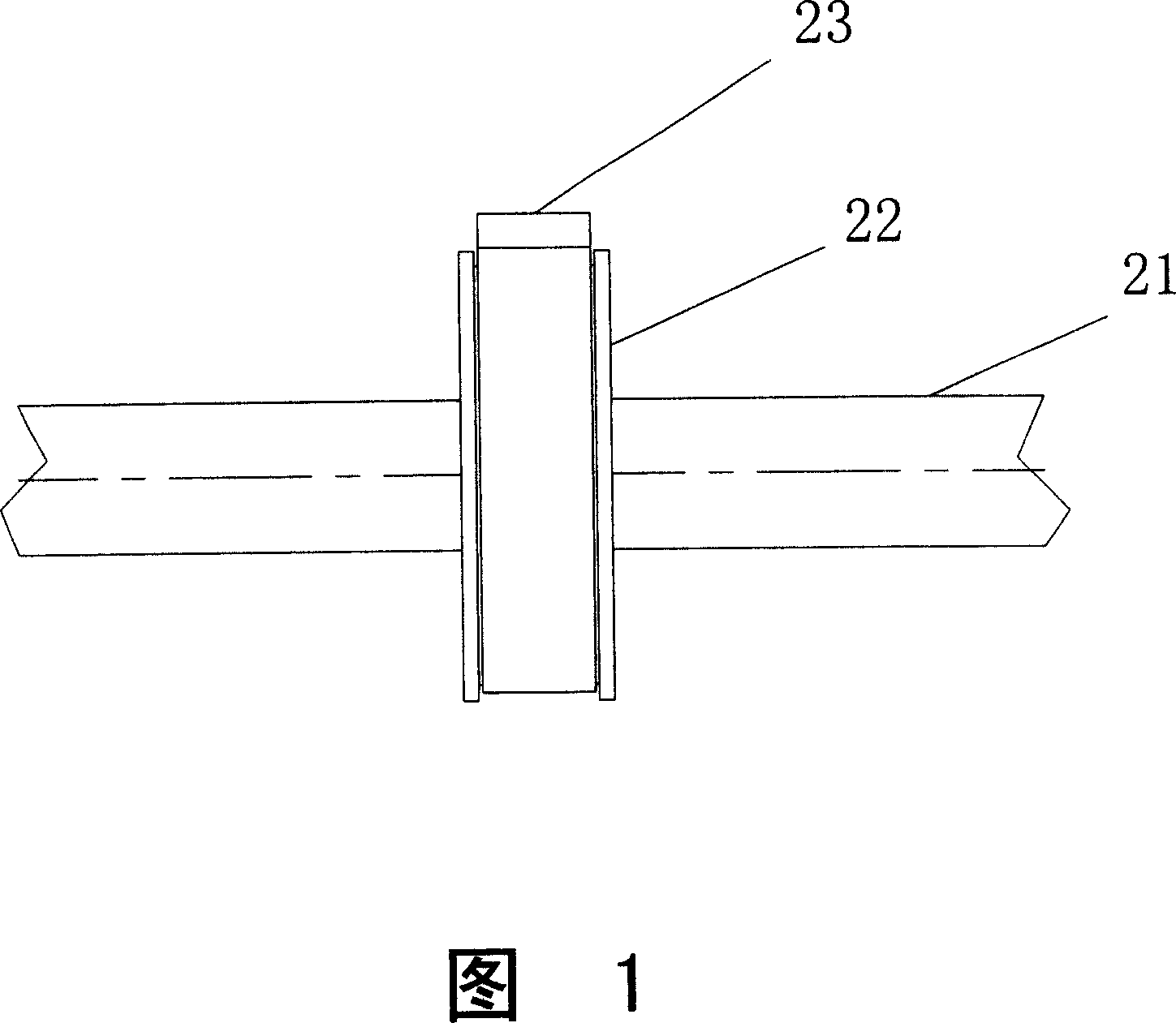

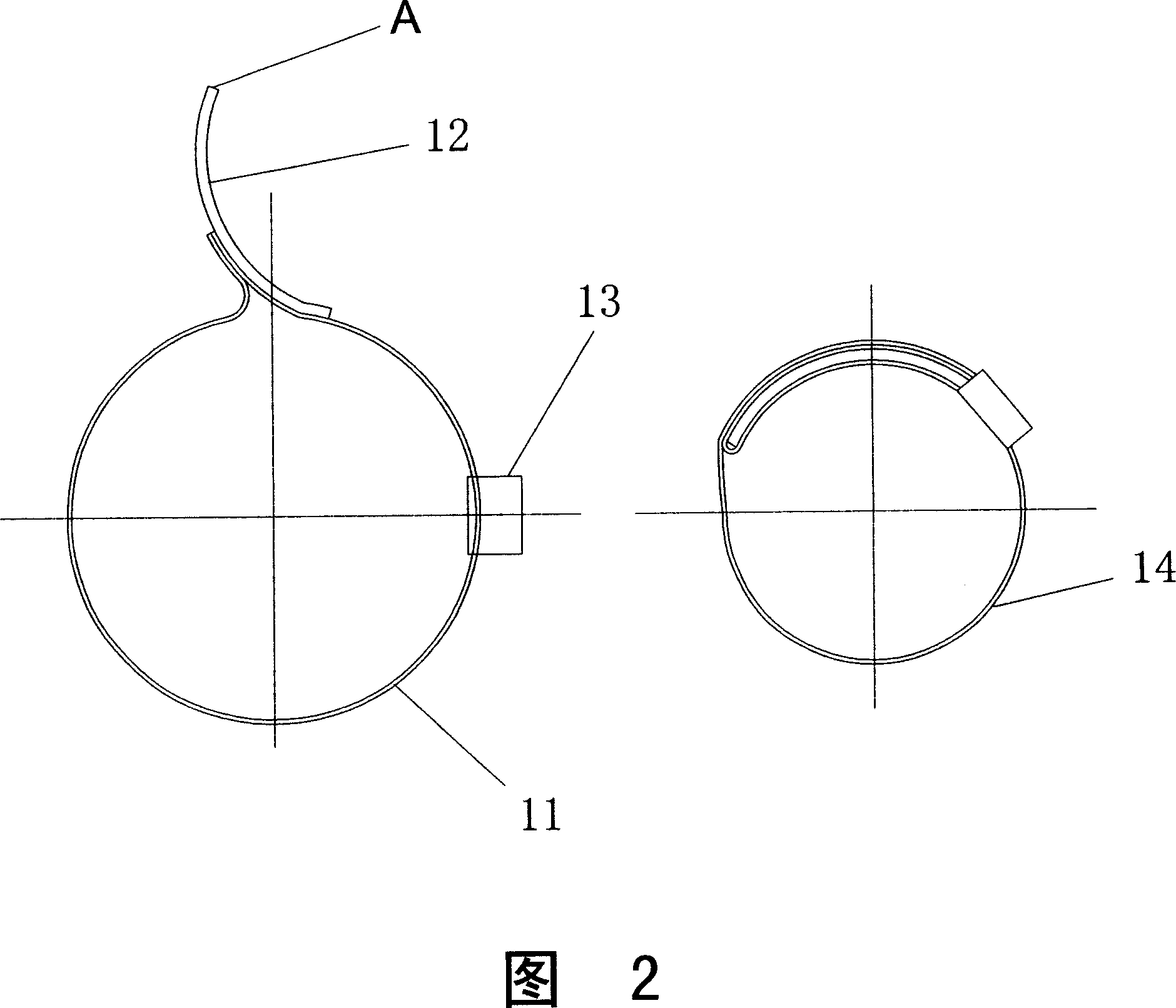

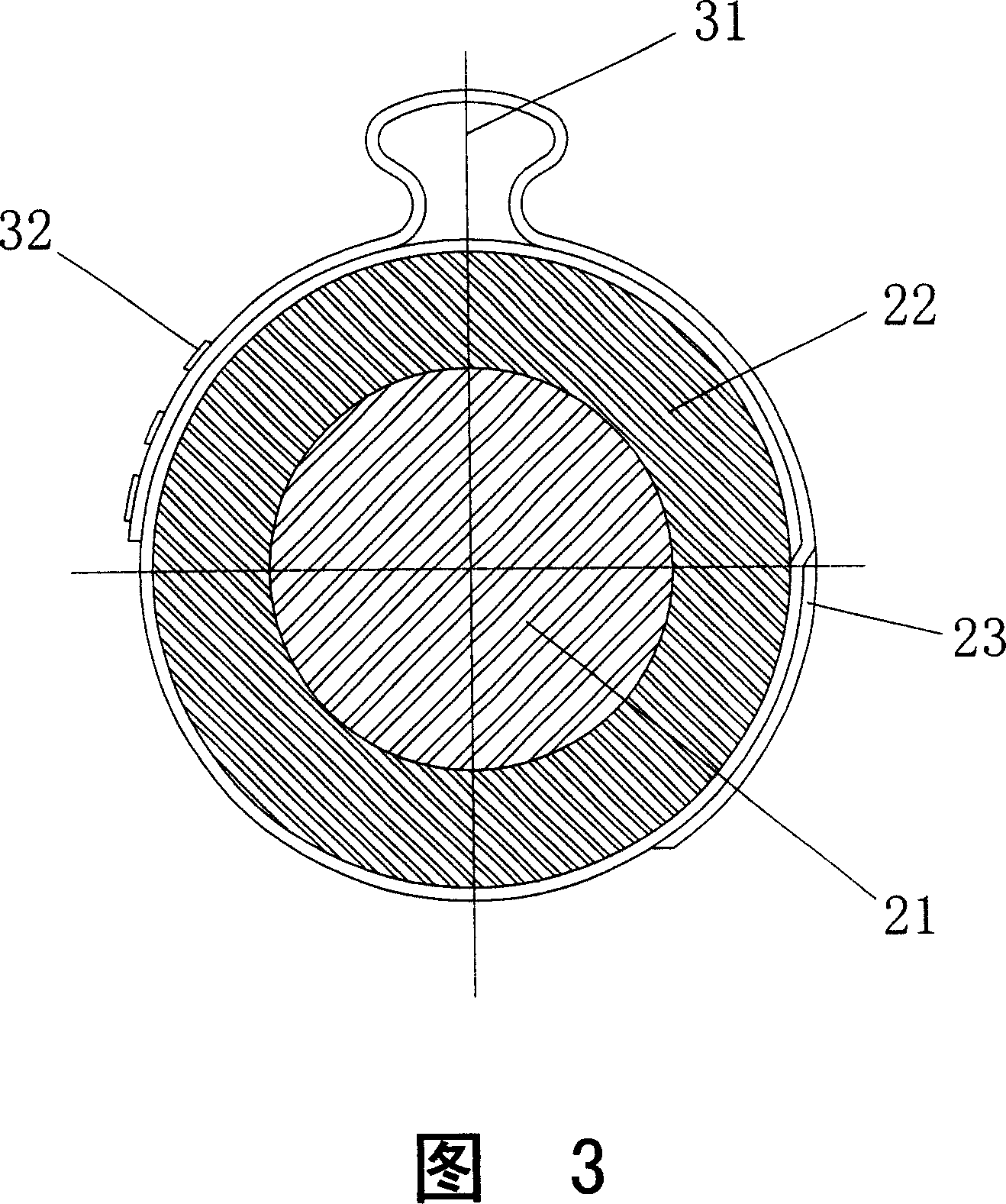

[0019] Figures 2 and 3 show the structure of the stabilizer bar with clamps. A limit ring 22 is sleeved on the body of the stabilizer bar 21 , the limit ring 22 is annular and made of rubber material, and its inner wall is closely attached to the stabilizer bar 21 . A single-eared stepless clamp 23 is arranged on the periphery of the limit ring 22 , and the clamp 23 is also annular with no steps and gaps on its inner surface, thereby ensuring that the entire inner surface is in close contact with the clamped limit ring 22 . Referring to FIG. 4 , the clamp 23 is made of stainless steel. The top of the clamp 23 has a boss 31 with an ear socket, so it is called a single ear. The clip 23 itself is connected by three raised blocks 32 .

[0020] When the clamp 23 needs to be locked, it is only necessary to tighten the top boss 31 with special calipers in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com