Polishing pad release liner system

a technology of release liner and polishing pad, which is applied in the direction of lapping tools, metal-working equipment, manufacturing tools, etc., can solve the problems of increasing the chance of the operator either damaging the polishing pad or injuring himself/herself, and reducing the operational life of the polishing pad, so as to achieve easy and safe removal, easy removal, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

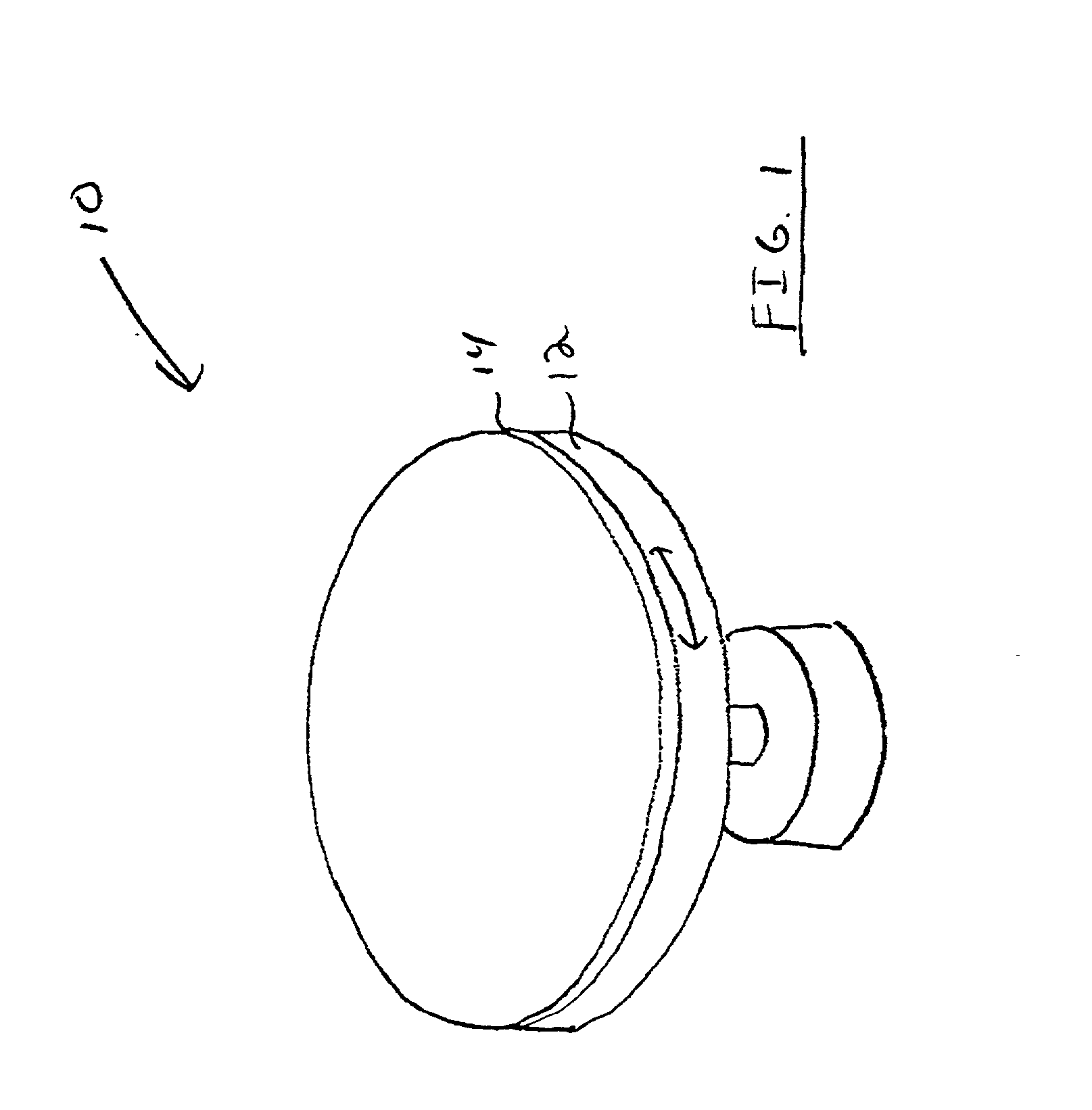

[0023] Referring now to the drawings and particularly to FIG. 1, there is shown therein a perspective view representative of an exemplary polishing fixture 1 0. The polishing fixture 10 includes a disk 12 that is operative to rotate. Mounted to the disk 12 is a polishing pad 14. When a semiconductor wafer is placed adjacent the polishing pad, the relative movement between surfaces of the pad and the wafer facilitates polishing and planarizing of the wafer.

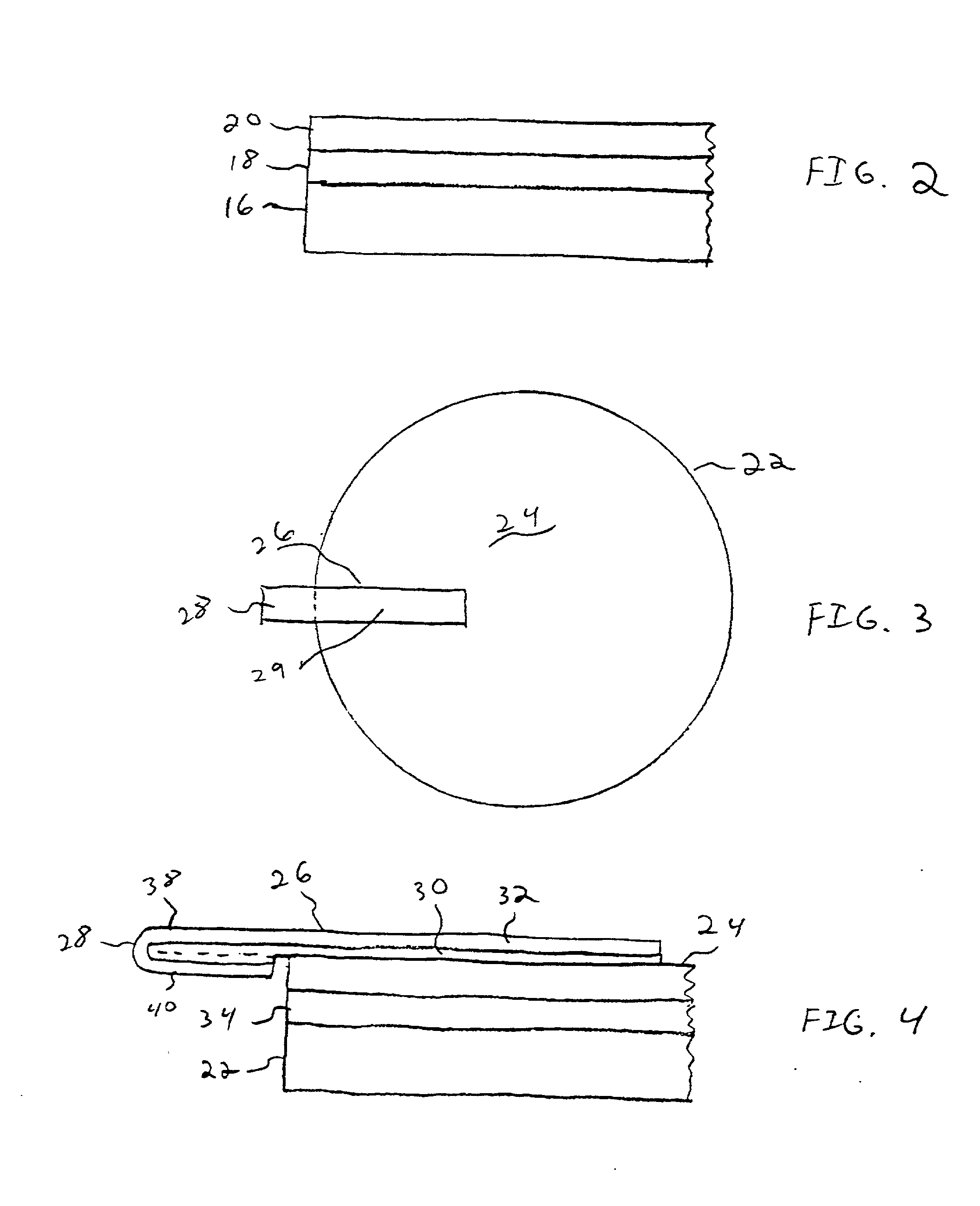

[0024] FIG. 2 shows an exemplary prior art polishing pad 16 prior to being mounted to a polishing fixture. The polishing pad 16 is manufactured with an adhesive layer 18 which facilitates adhesion of the pad 16 to a polishing fixture. However to prevent contamination of the adhesive layer 18 during shipment and storage, the polishing pad 16 is manufactured with a protective release liner 20 over the adhesive layer 18. The protective release liner 20 is typically comprised of a flexible plastic sheet that is operative to peel away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com