Apparatus for storing and moving a cassette

a cassette and apparatus technology, applied in the field of substrate processing, can solve the problems of increasing the cost of fabrication facilities, only a single cassette can be stored in the station,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following description, the term "substrate" broadly covers any object that is being processed in a semiconductor device processing system. The term "substrate" includes, for example, semiconductor wafers, flat panel displays, glass plates or disks, and plastic workpieces.

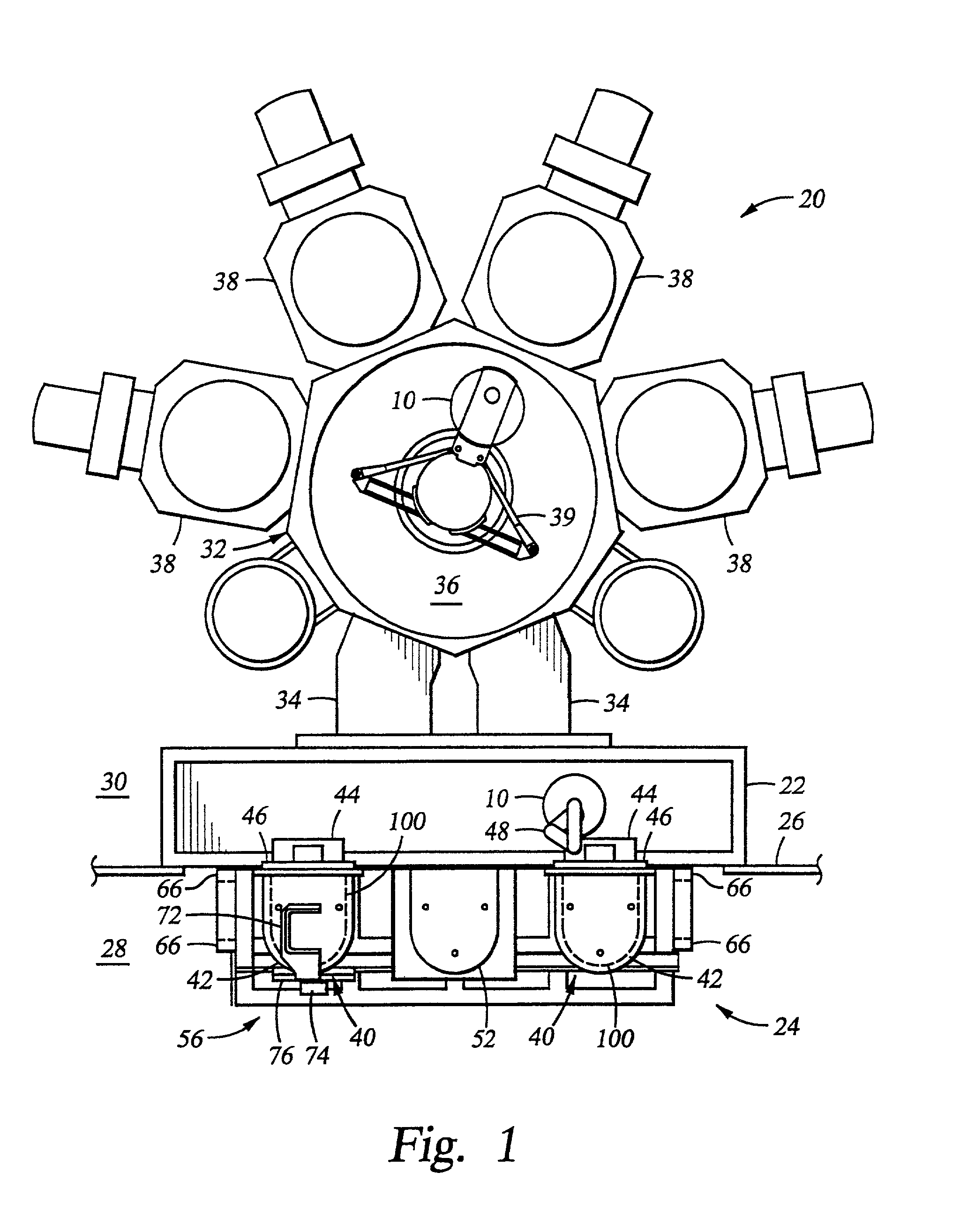

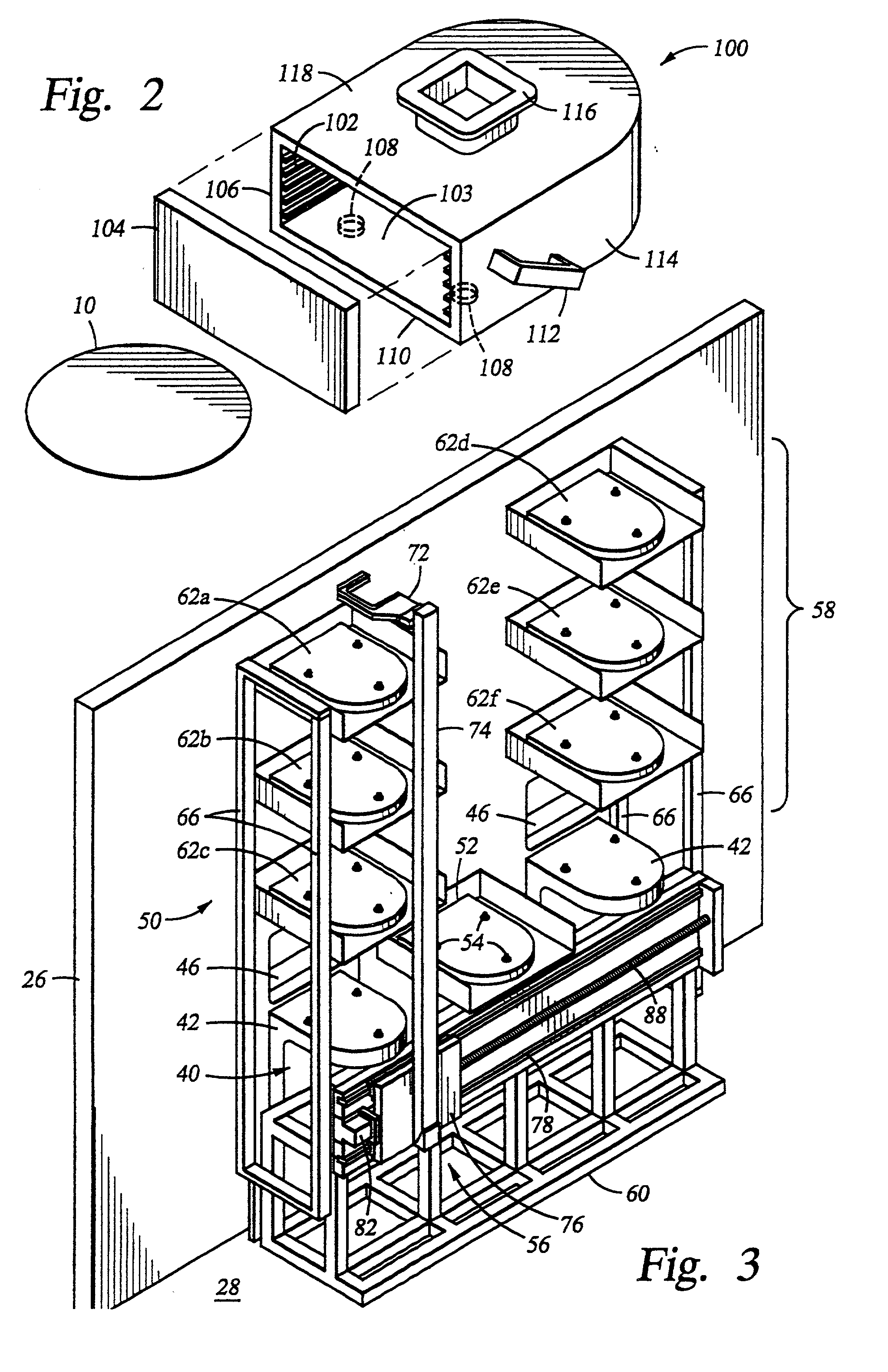

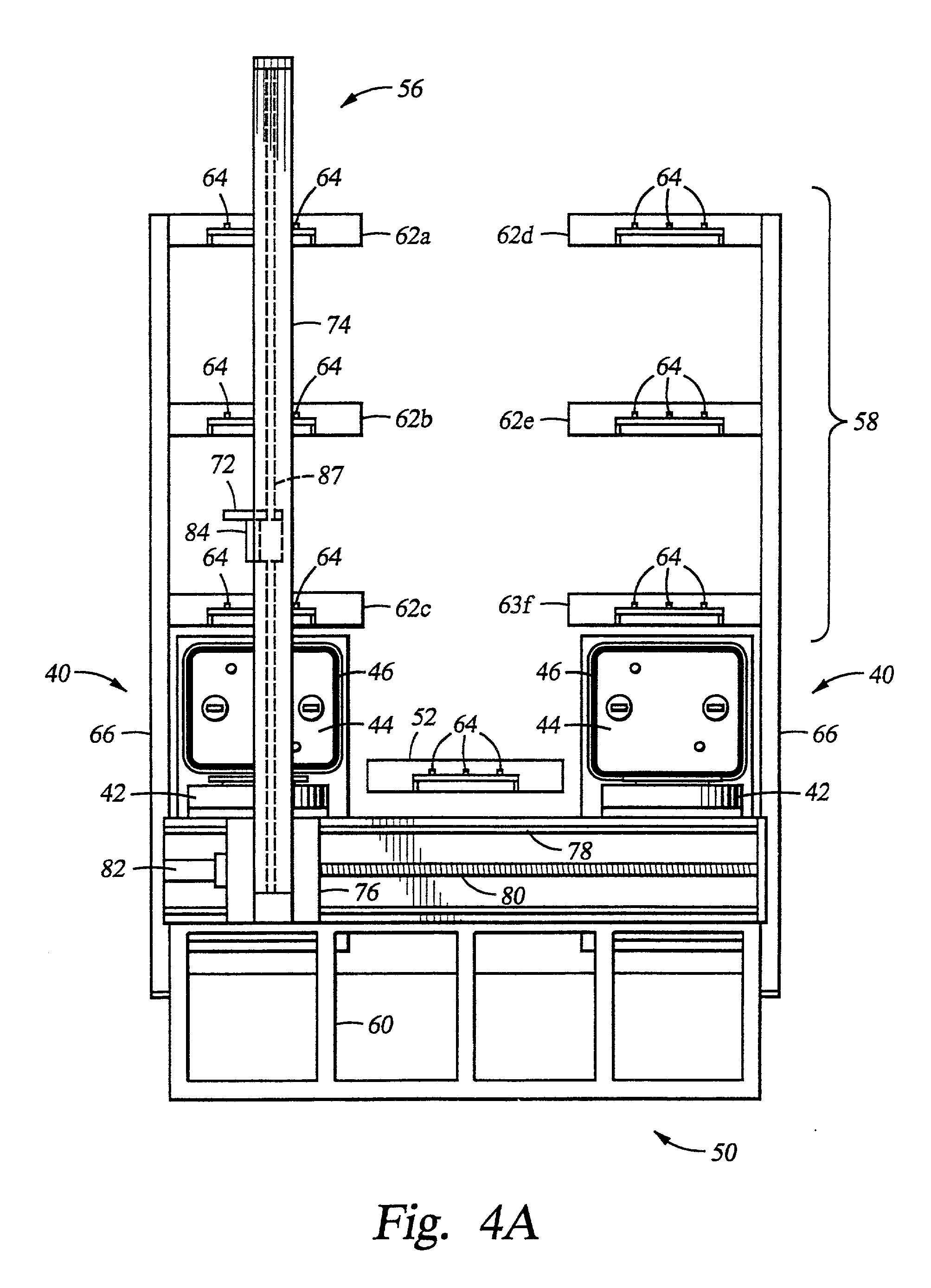

[0025] FIG. 1 is a top view of a processing station 20 of the present invention in which one or more substrates 10 are processed. The processing station 20 has a front-end staging area 22 which is separated from a loading and storage area 24 by a cleanroom wall 26. Cleanroom wall 26 separates a cleanroom 28, where loading and storage area 24 is located, from a gray area 30, where a processing system 32 is housed. The loading and storage area 24 is where cassettes of substrates are delivered and loaded / unloaded into / from the processing station 20. Processing system 32 may include one or more load lock chambers 34, a central transfer chamber 36, and a plurality of processing chambers 38. Inside processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com