Prosthetic liner

a technology of prosthetic lines and silicone, applied in the field of prosthetic lines, can solve the problems of not providing substantial resistance to silicone distension, the weight of the suction liner,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

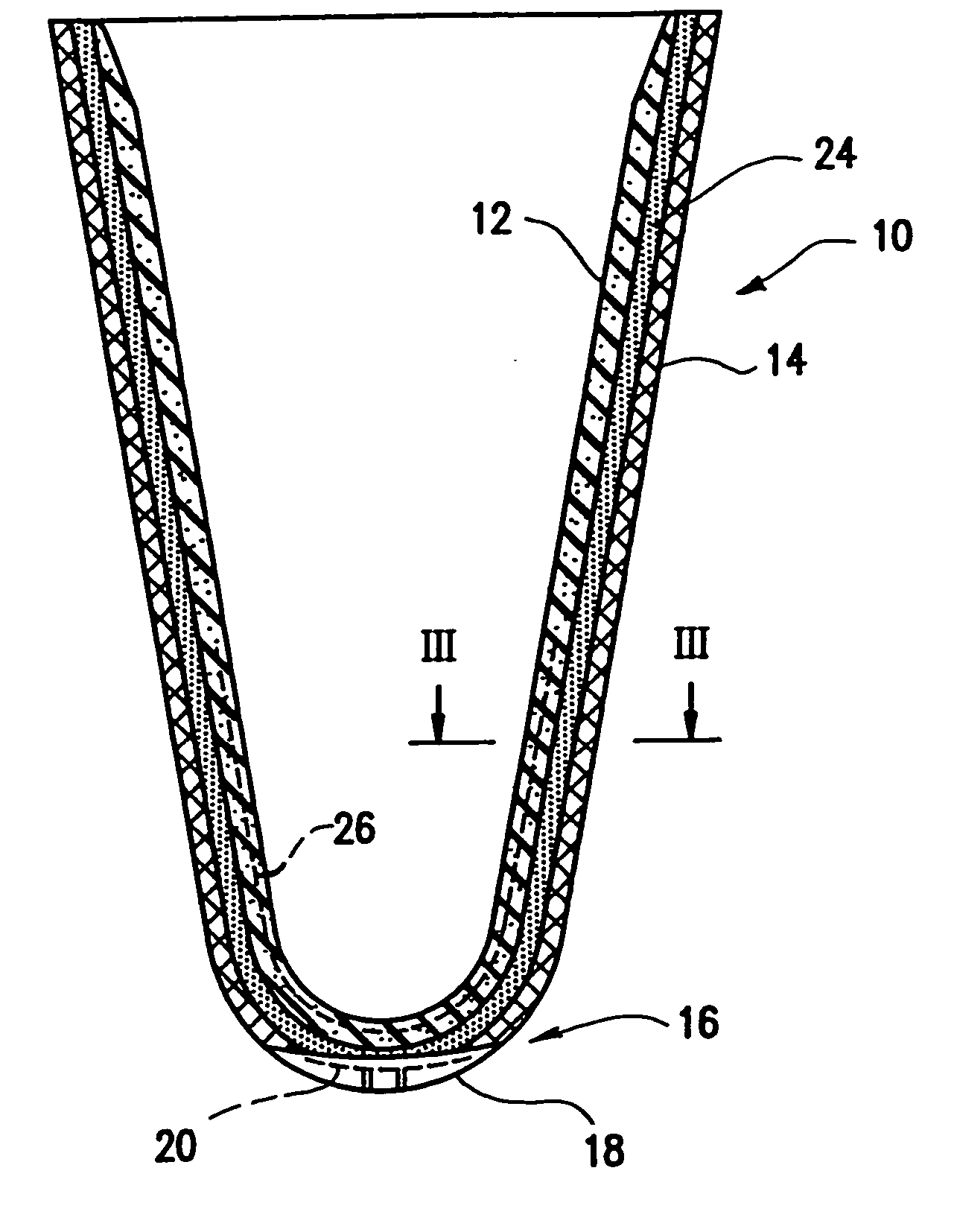

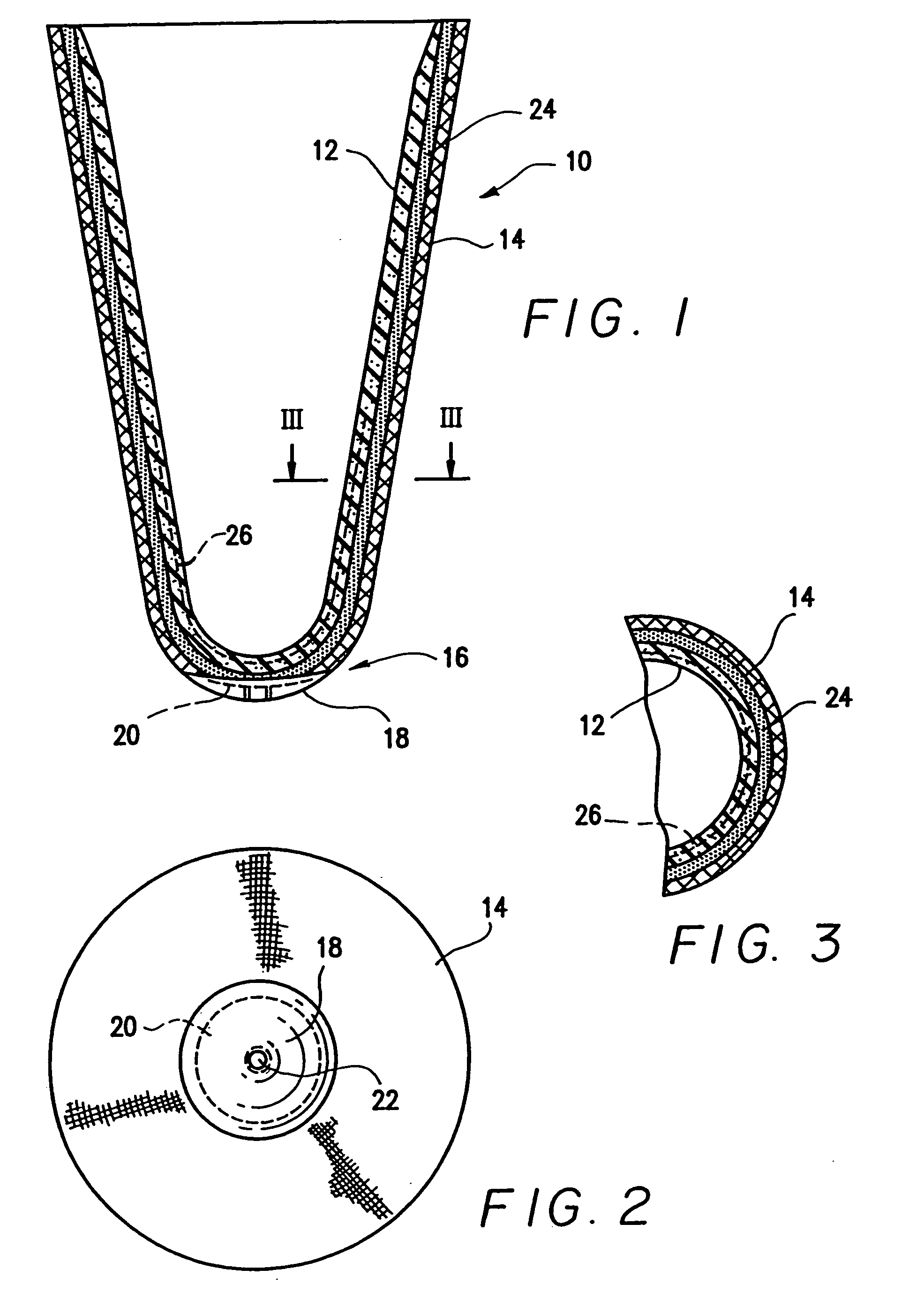

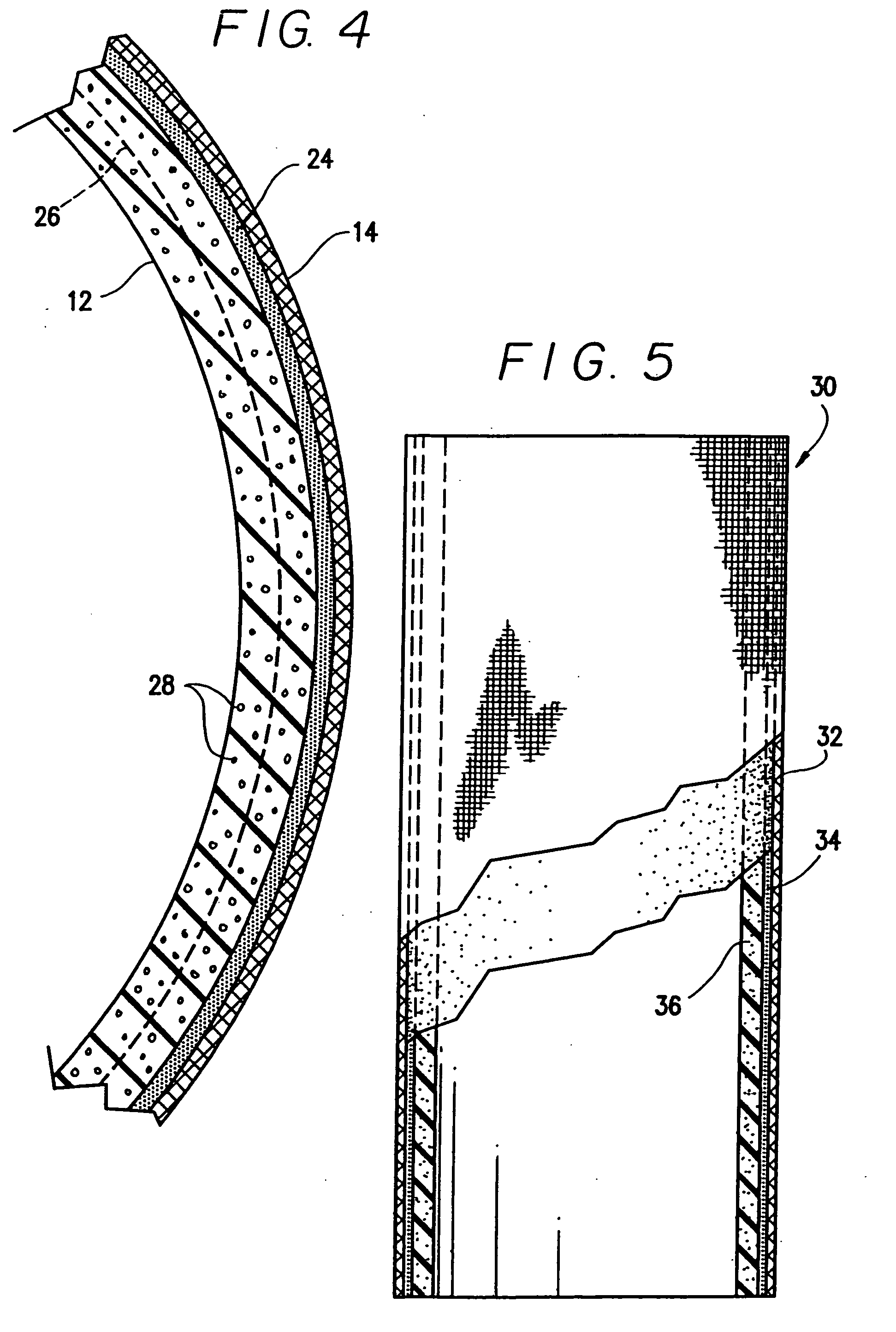

[0034] FIG. 1 schematically illustrates in a cross-section view a prosthetic suction liner 10 formed in part of a composite elastic material 12 on its interior surface and an elasticized fabric layer 14 on its exterior surface at least up to its distal end area 16, where a distal end cap 18 having embedded therein a rigid prosthetic connector 20 formed, for example, of aluminum or other metal, or rigid plastic such as Nylon.

[0035] The liner 10 is formed as a close ended tapered tubular element, as is conventional for such suction liners. The distal end cap 18 firmly joins the prosthetic connector 20 to the suction liner 10 while providing a cushioning and stabilizing surface at the distal end of the liner. The prosthetic connector 20 includes preferably a threaded aperture 22 for providing access to a threaded prosthetic pin connector in a manner well known in the art.

[0036] FIG. 2 shows the suction liner in an end view as seen from the distal end of the liner.

[0037] FIG. 3 is a cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com