Air sealable container with automatically actuable pressure equalizing valve

a technology of automatic actuation and sealable containers, which is applied in the direction of packaging, other accessories, clamping mechanisms, etc., can solve the problems of frequent opening of the valve and forgetting by users, requiring manual intervention by users, and not being able to achieve the effect of automatic actuation and sealing, low cost and high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

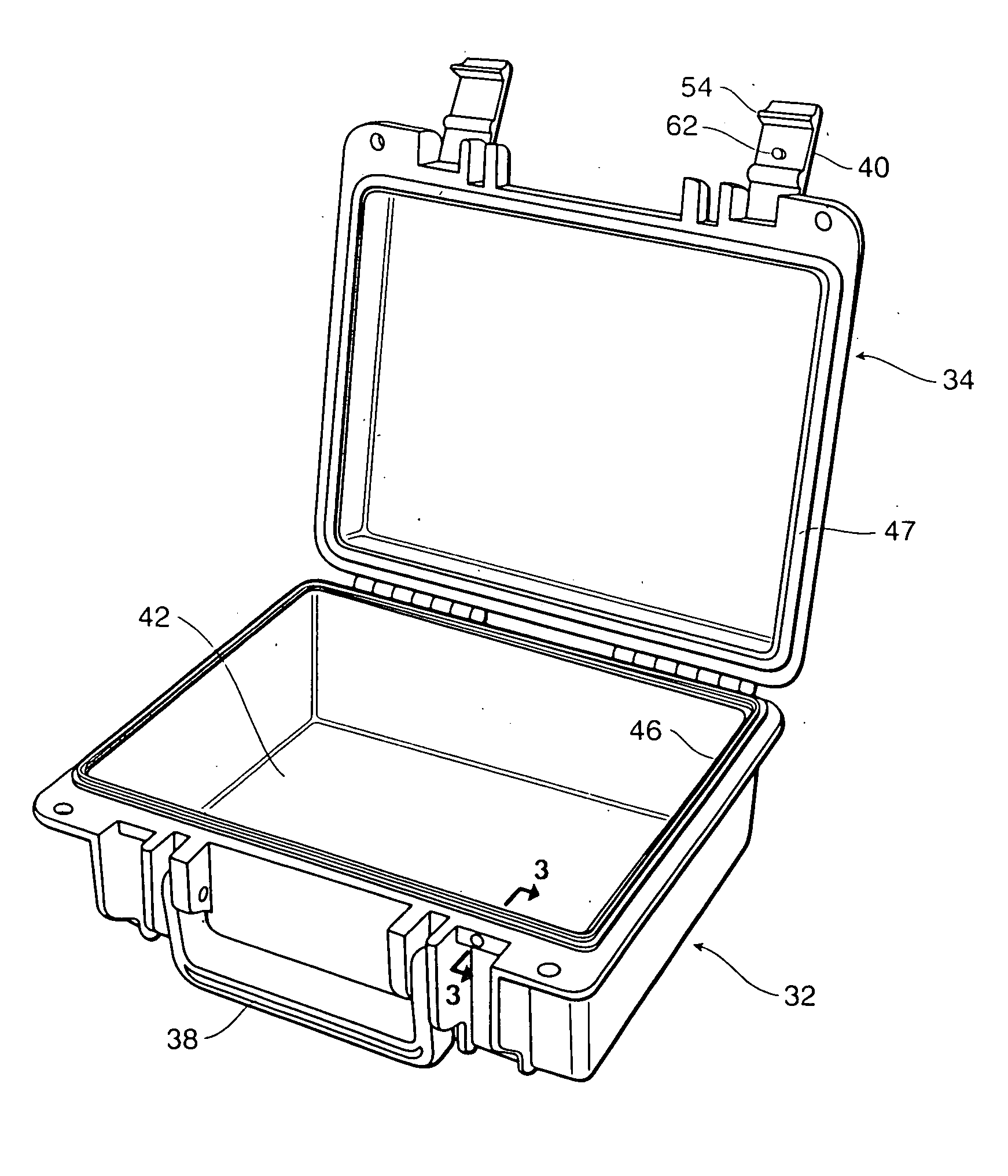

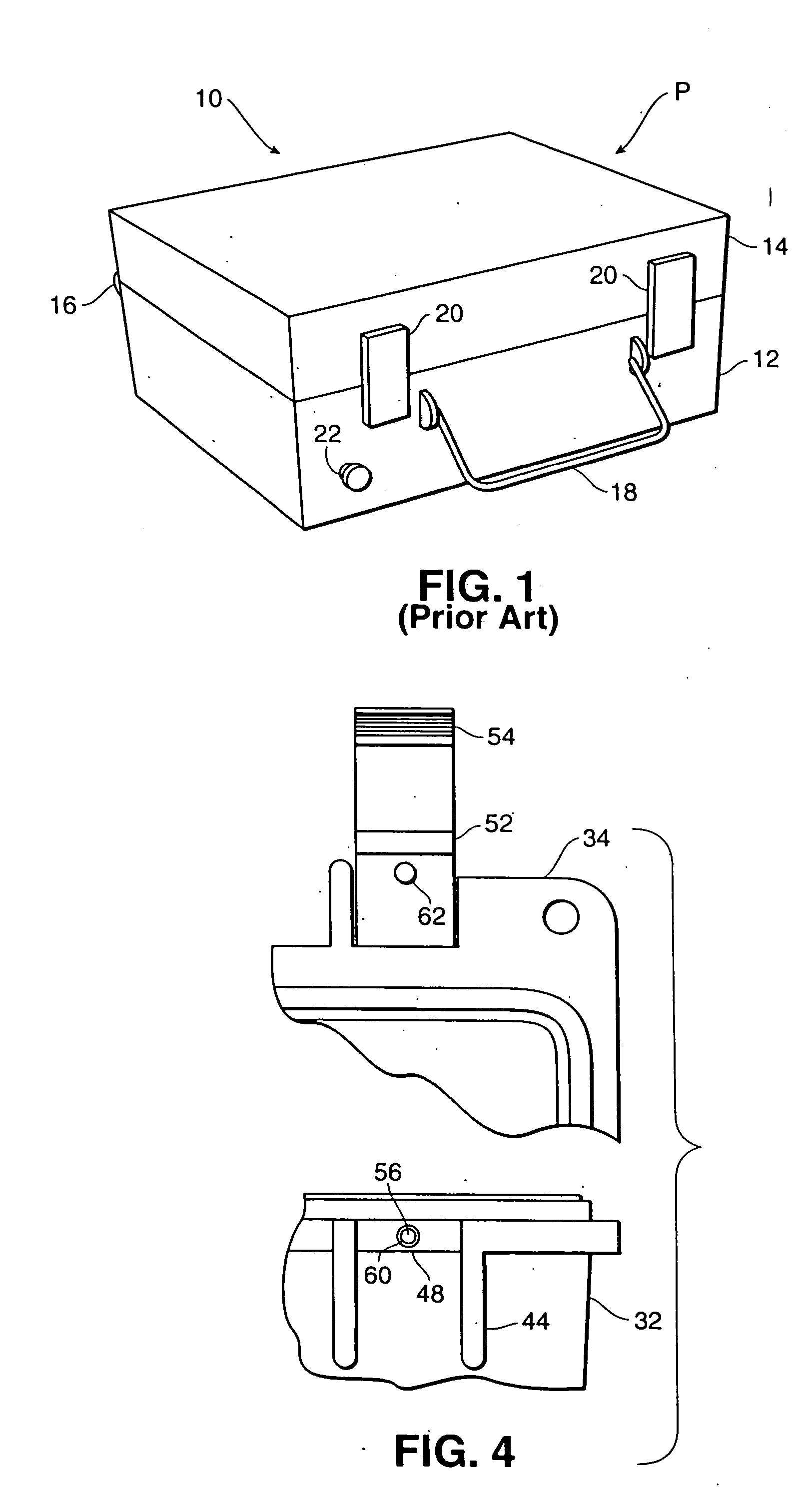

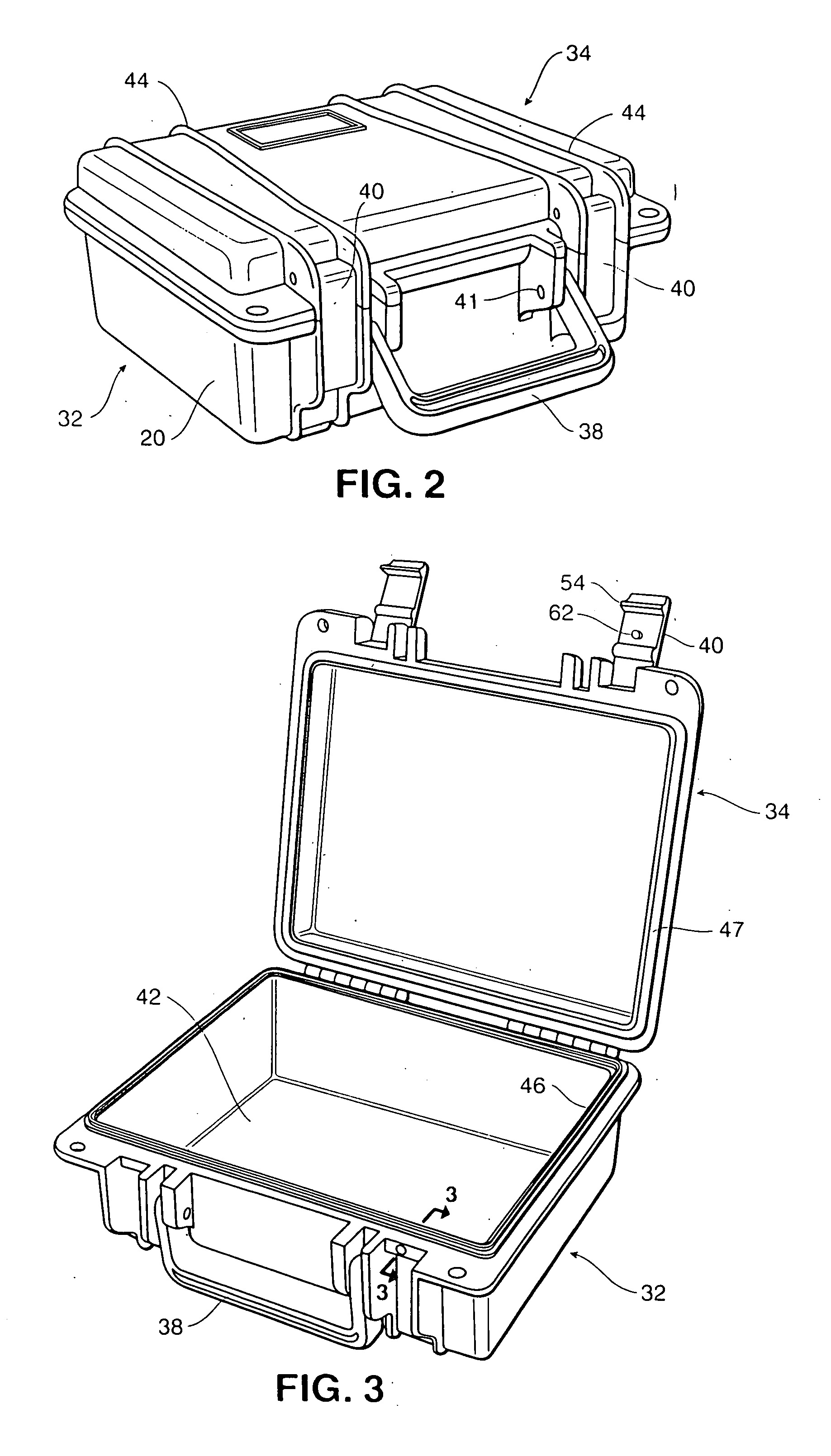

[0038] Referring now in more detail and by reference characters to the drawings which illustrate practical embodiments of the present invention, P designates a typical prior art fluid sealed container 10, having a base 12 along with a lid 14 hingedly mounted thereon through conventional hinges 16. The carrying case may be conventionally provided with a handle 18 for grasping by the hands of the user. Moreover the lid 10 is capable of being locked to the base in a fluid sealed condition, through the use of latches 20, all as best shown in FIG. 1.

[0039] The prior art containers which were fluid sealed typically included some valve to allow for pressure equalization between the interior of the container and the ambient atmosphere. In this case, a conventional pressure type relief valve 22 was provided. This pressure relief valve could be of relatively simple construction and frequently relied upon a screw which was partially unthreaded from an opening through the containing wall, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com