Magnetic head for perpendicular recording and magnetic disk storage apparatus mounting the head

a magnetic disk storage and perpendicular recording technology, applied in the direction of heads with metal sheet cores, special recording techniques, instruments, etc., can solve the problems of thermal fluctuation loss of recording written magnetization on a medium, difficulty in enhancing recording density, and disturb writing bits written

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

[0030] (First Embodiment)

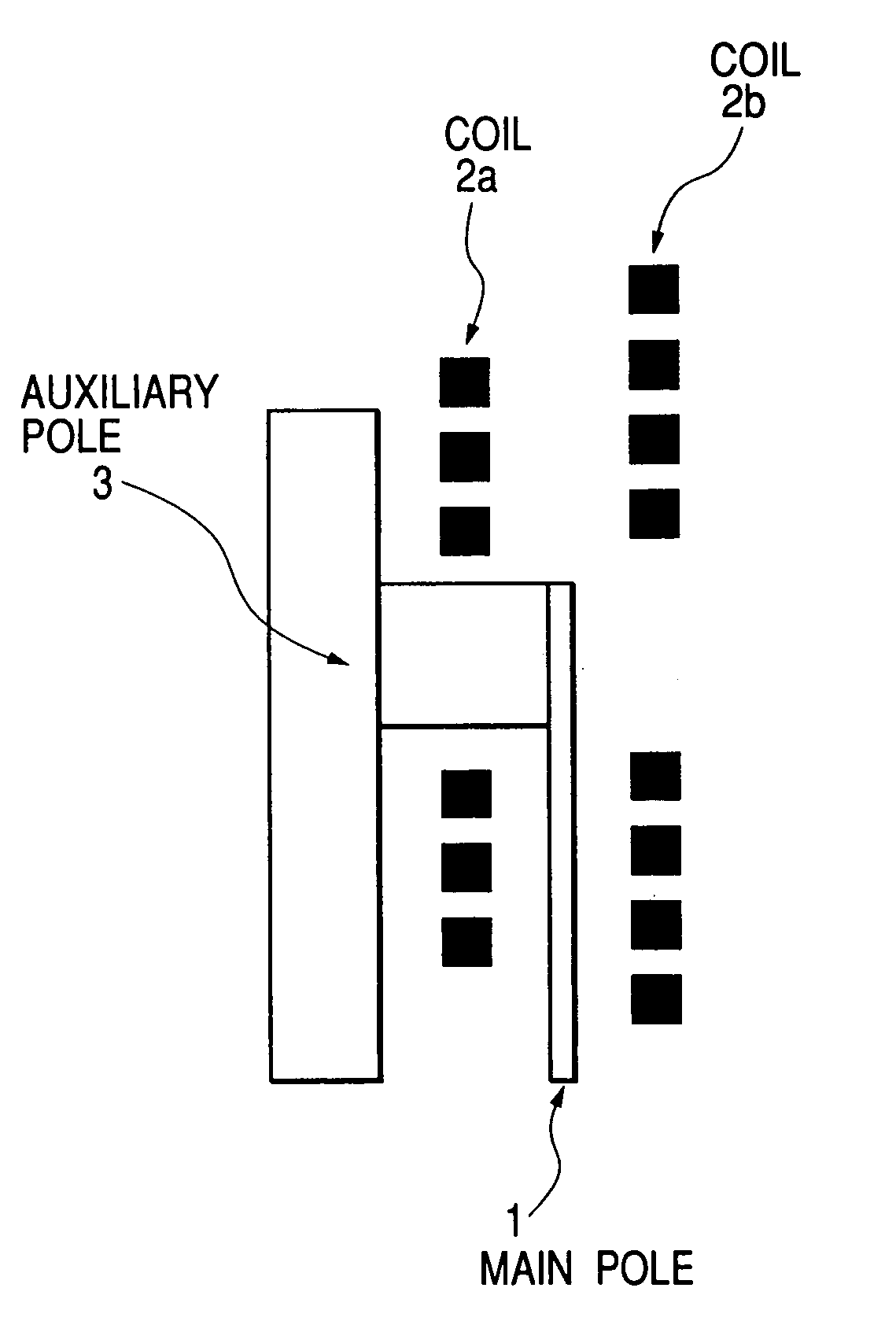

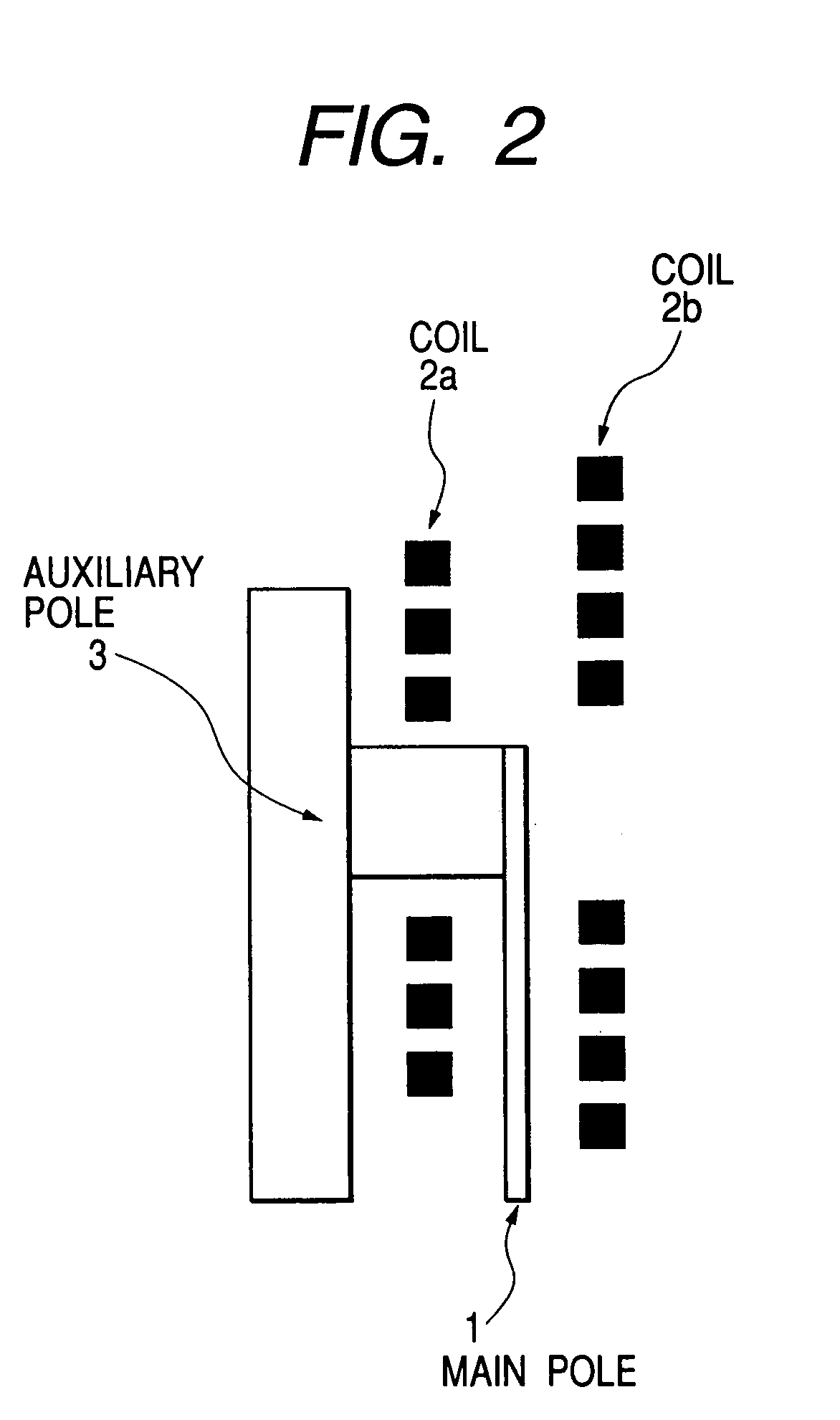

[0031] FIG. 2 is a sectional model view showing the first embodiment of a single pole type write head used in the present invention. In this embodiment, the write head is composed of a main pole 1, an auxiliary pole 3 and thin-film conductor coils 2a and 2b located on both sides of the main pole 1 in a manner to sandwich the main pole 1. The schematic model view of FIG. 2 sectionally illustrates the magnetic head in the disk rotating direction from the center of the disk track, in which view the magnification factors are not unified. The two coils 2a and 2b may be composed so as to be connected in the disk rotating direction so that a magnetic field of the same polarity may be generated at the tip of the main pole 1. Or, these coils 2a and 2b may be composed to separate these coils 2a and 2b from each other so that each coil generates the magnetic field of the same polarity at the tip thereof.

[0032] As is obvious from FIG. 2, in this embodiment, the number o...

second embodiment

[0040] (Second Embodiment)

[0041] FIGS. 7A, 7B show the magnetic head according to the second embodiment of the invention. The views of these figures show the magnetic flux density distribution in the case that the distance D1 between the main pole 1 and the auxiliary pole 3 (that is, the distance between the opposed side of the main pole 1 to the auxiliary pole 3 and the opposed side of the auxiliary pole 3 to the main pole) is changed into 3 .mu.m, for comparing the head of the conventional structure (see FIG. 7A) with the single pole type head of the present invention (see FIG. 7B). In the conventional structure shown in FIG. 7A, by narrowing the distance D1 more than the distance D1 of 15 .mu.m, the distribution of a greater magnetic flux density is made wider. On the other hand, in the head structure of the invention shown in FIG. 7B, even if the distance D1 between the main pole 1 and the auxiliary pole 3 is made narrower, the magnetic flux density of the under layer 20 is made...

third embodiment

[0044] (Third Embodiment)

[0045] FIG. 9 is a schematic sectional view showing a magnetic head according to a third embodiment of the present invention, in which view the read element 7 and the auxiliary pole 3 are located in a manner to sandwich the main pole 1 and the coils are located on both sides of the main pole in an asymmetrical manner, that is, in a manner to apply respective magneto-motive forces onto both sides of the main pole as described with respect to the foregoing first and second embodiments. The section is cut on the center of the track in the disk rotating direction.

[0046] In this embodiment, no auxiliary pole 3 is provided between the read element 7 and the main pole 1, so that the distance D3 between the read element 7 and the opposed side of the main pole 1 to the read element 7 may be made narrower by the film thickness. Moreover, since the magnetic flux being flown from the main pole 1 to the upper shield 9 is suppressed, it is preferable to make the distance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com