Form support for supporting a disposable mold form

a mold form and support technology, applied in the direction of forms/shuttering/falseworks, shaping building parts, construction, etc., can solve the problems of corroding and expanding of the mold form, affecting the construction effect,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

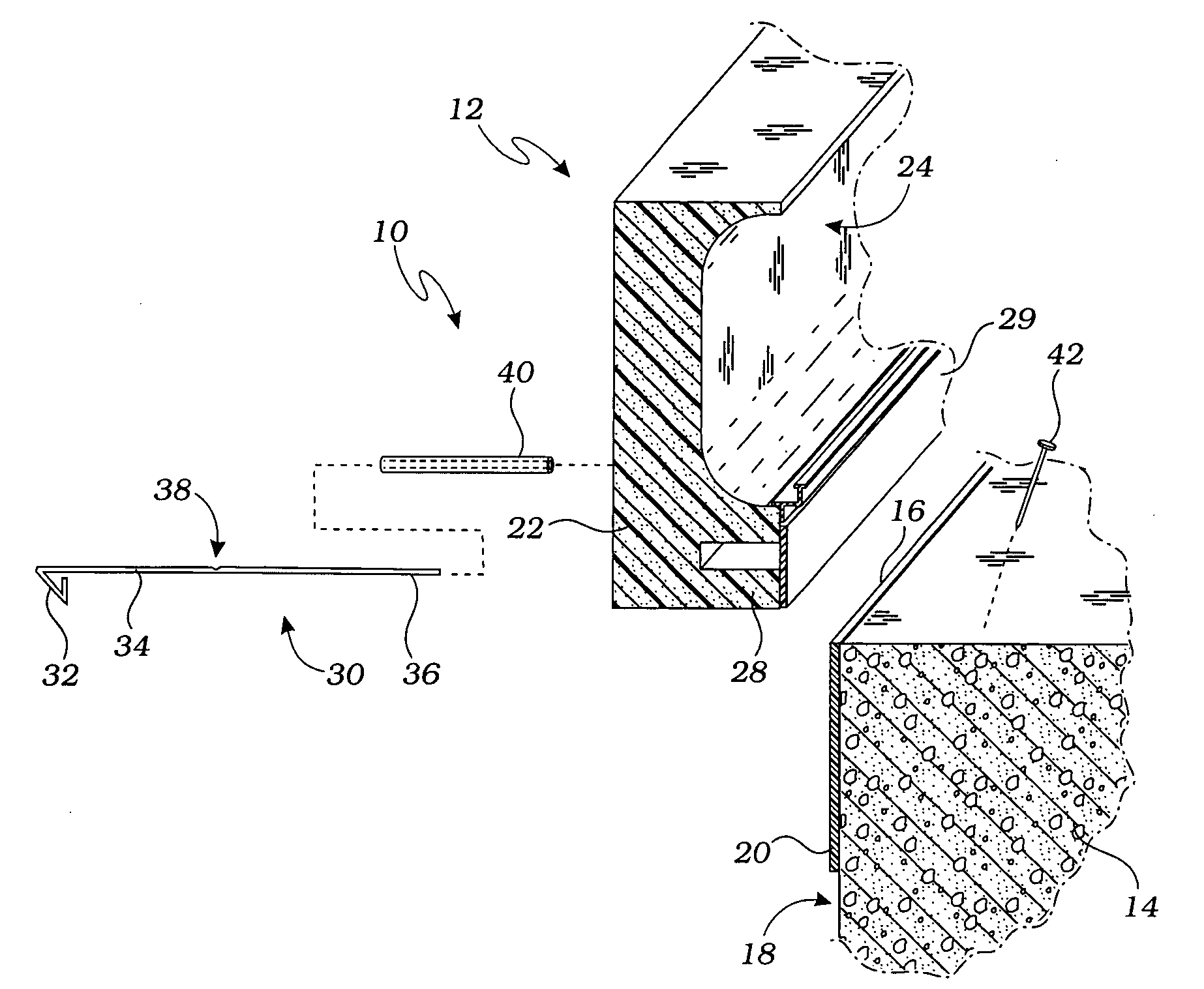

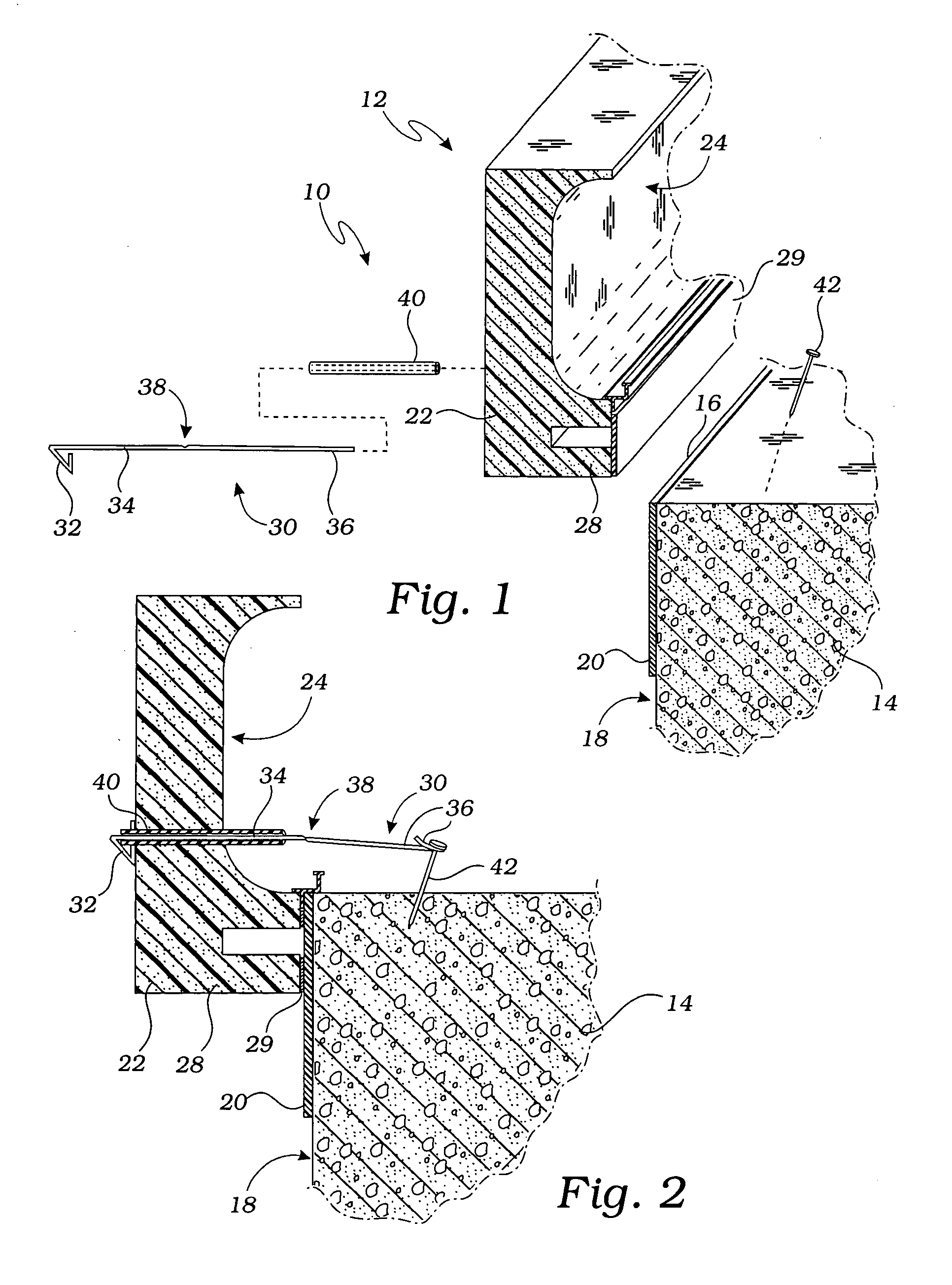

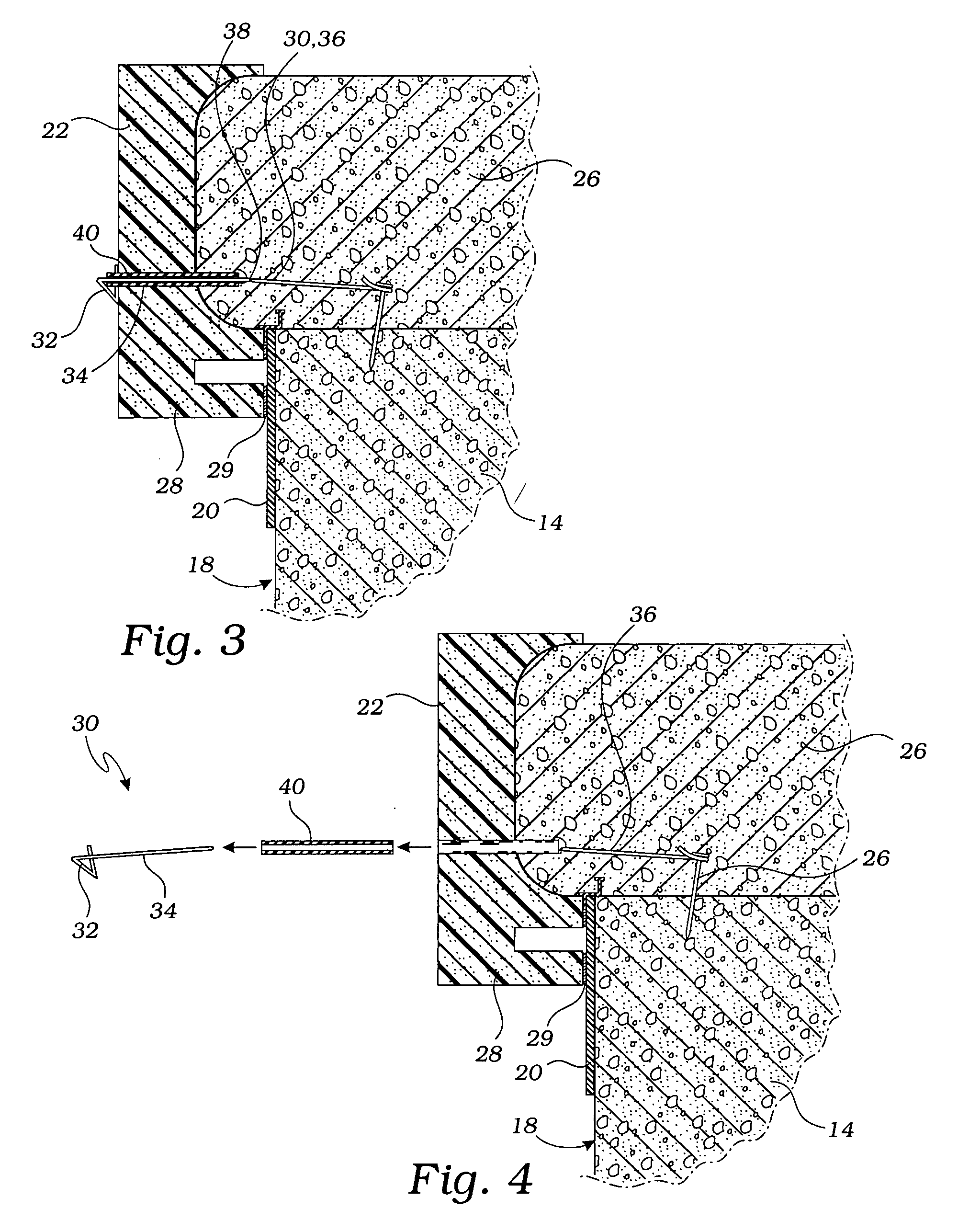

[0022] The above-described drawing figures illustrate the invention, a form support 10 for supporting a disposable mold form 22 mounted on a bond beam 14 for forming a cement coping 26 during the construction of a swimming pool. The form support 10 includes a tie wire 30 and an elongate tube 40, which are described in greater detail below

[0023]FIG. 1 illustrates how the disposable mold form 22 is mounted on the bond beam 14, which is formed by the upwardly extending side walls of the swimming pool. The bond beam 14, and the entirety of the upwardly extending side walls, may be formed in any conventional manner, and ordinarily are fabricated of concrete and integral with a bottom wall (not shown). The generally vertical or upwardly extending walls are enlarged somewhat at their upper ends to form the bond beam 14 which is rather standard practice. The bond beam 14 has an upper edge 16 and an inner face 18 or surface. The inner face 18 has a water-impervious finish 20 secured thereto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com