Arrangement of a running roller on a coupling journal of a moveable shaft coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

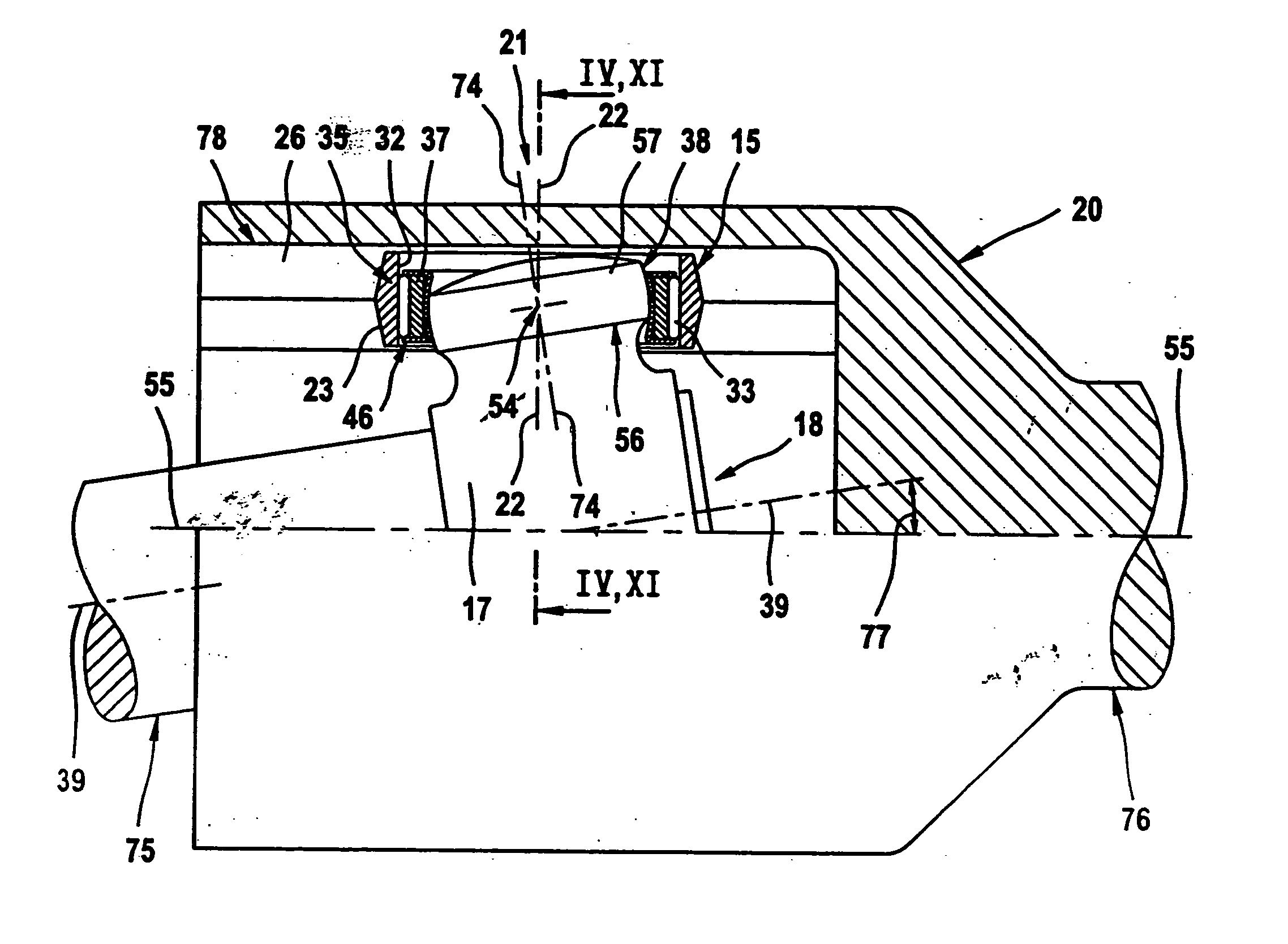

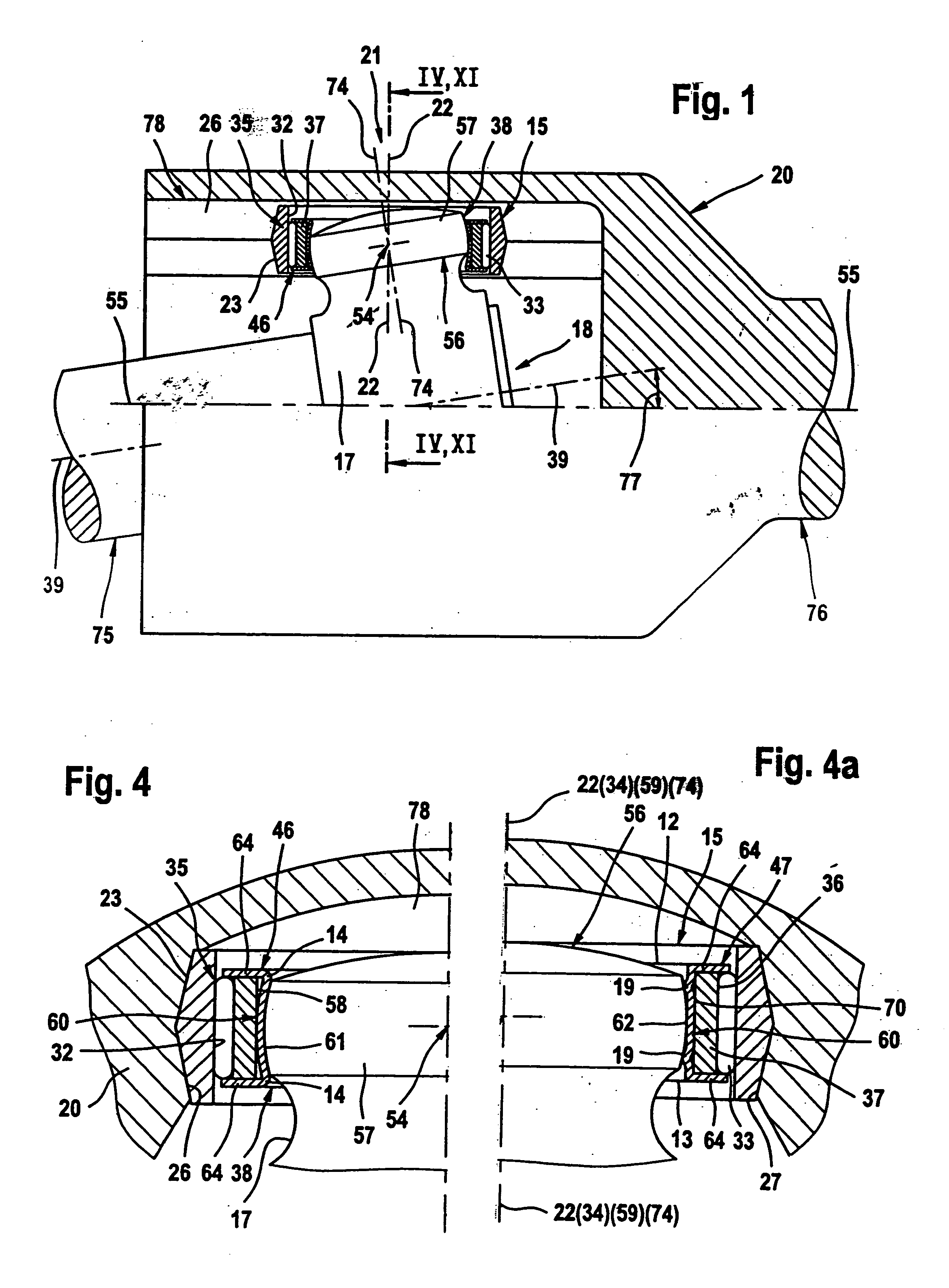

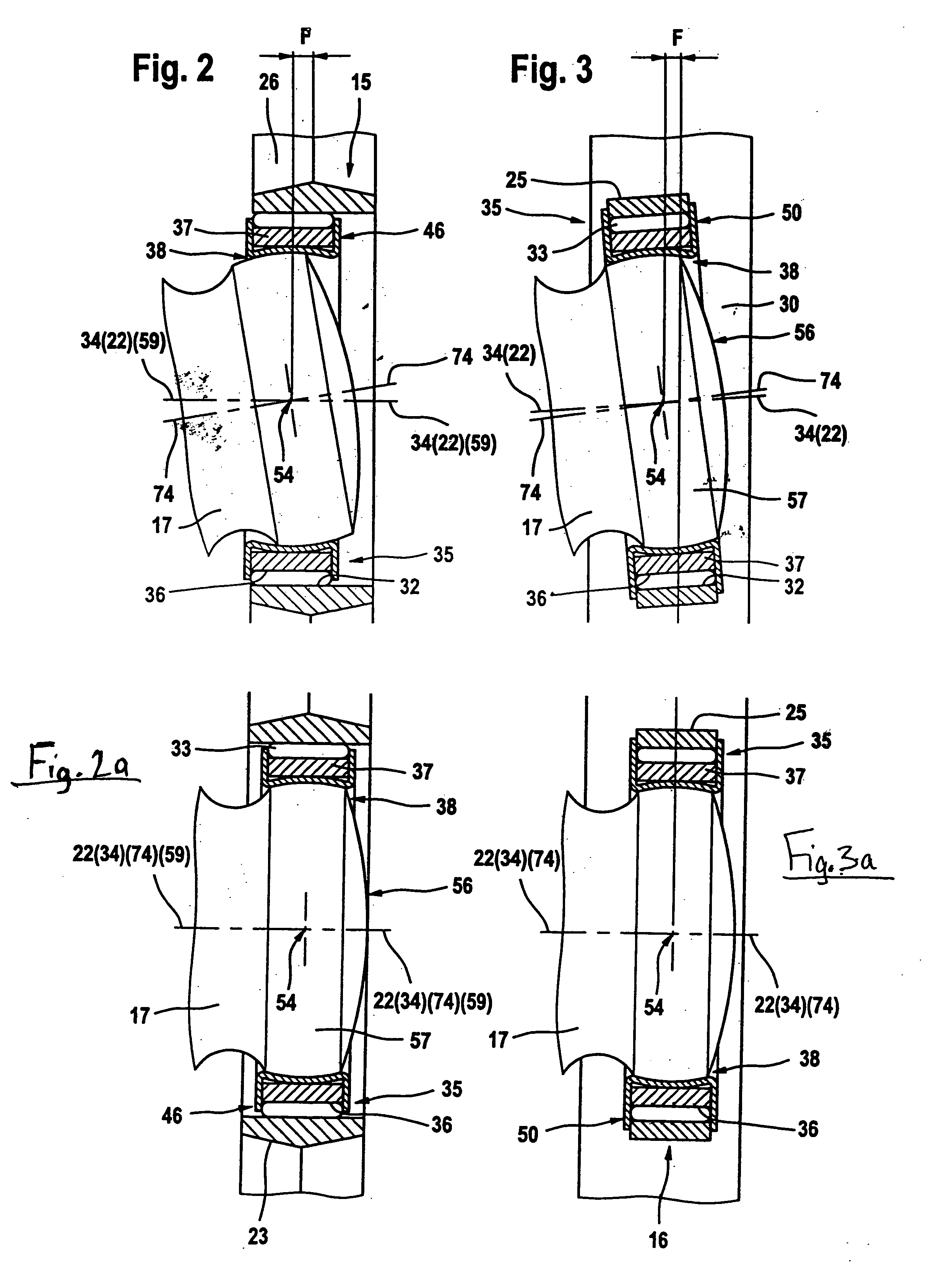

[0030] Referring first to FIGS. 1, 2 and 4, a moveable shaft coupling 21 is used for the rotationally fixed connection of two drive shafts 75 and 76 which with respect to their central axes 39-39 and 55-55 may assume a bending position forming a bending angle 77 or a straight position with their central axes being aligned coaxially.

[0031] That coupling half 18 of the shaft coupling 21 which is assigned fixedly in terms of movement to the drive shaft 75 includes at least one coupling journal 17 which is oriented with its central axis 74-74 perpendicular to the central axis 39-39 of the drive shaft 75 and which is connected rotationally and pivotably movably to a running roller 15 by a series arrangement that includes a ball joint 38 and a radial rolling bearing 35.

[0032] The complementary coupling half assigned fixedly in terms of movement to the drive shaft 76 is configured as a coupling drum 20 which has on its inner circumference, for each running roller 15, an axial groove 78 w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap