Method for preparing polymer particle

A technology of polymer particles and monomers, applied in the field of polymer particles, can solve the problems of difficult to control product form and performance, high monomer conversion rate, slow rate of seed absorption of monomers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

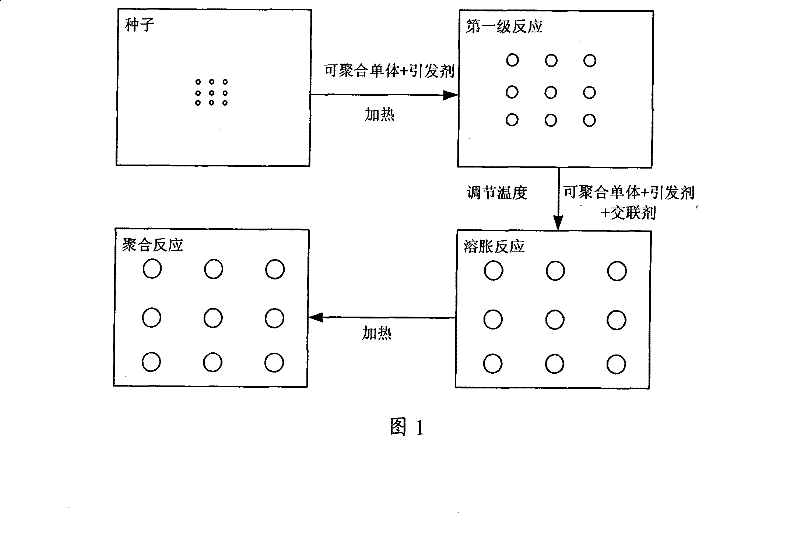

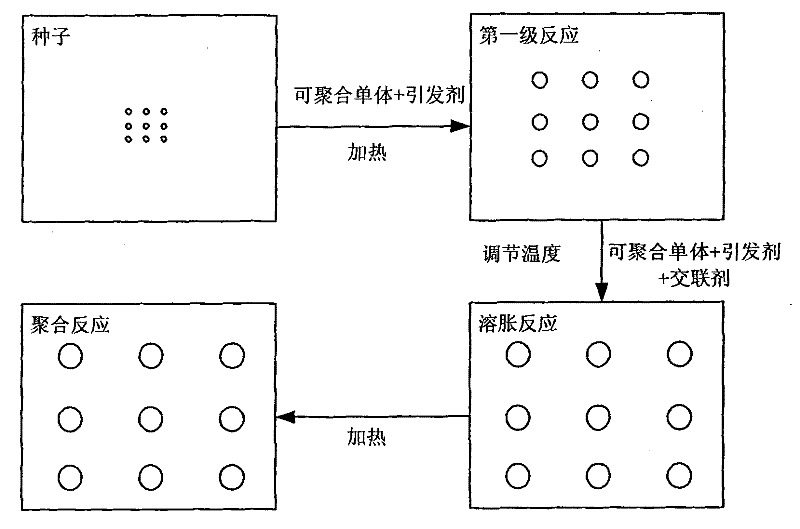

[0025] Such as figure 1 As shown, the present invention provides a method for preparing polymer particles, which includes the following steps, generally, it can be carried out under nitrogen protection.

[0026] A1. Suspend the pre-prepared monodisperse swellable seed polymer particles whose weight is the first preset value N1 in an aqueous solution containing a stabilizer and a surfactant. This step may also include stirring and heating process; the seed polymer particles can be prepared by existing techniques, such as dispersion polymerization, emulsion polymerization and the like. In general, steric stabilizers and surfactants are necessary, and surfactants can be anionic, nonionic and nonionic surfactants, such as SDS. The stabilizer, that is, the steric stabilizer, can be selected from one or more of the following compounds: cellulose ether, hydroxypropyl cellulose, polyalcohol (such as polyvinyl alcohol, etc.), polyvinylpyrrolidone, and various inorganic substances, su...

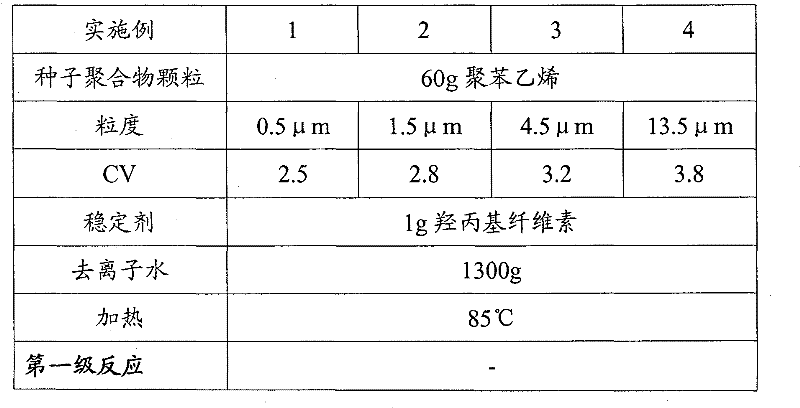

Embodiment 1

[0048] In a 5-liter reactor, pre-prepared 60 g of monodisperse swellable polystyrene particles as seeds, with a particle size of 0.5 μm and CV=2.5, were added to 1300 g of deionized water containing 1 g of hydroxypropyl cellulose; at 150 Stir and heat to 85 °C at a speed of rpm.

[0049] After mixing 800g styrene with 10g dibenzoyl peroxide, add 1500g water containing 0.5g KI, 0.5g hydroxypropyl cellulose and 4.0g Triton X-405, mix and emulsify, add at an increasing rate at 85°C Into the aqueous solution, for example, the initial speed is 1ml / min, the final speed is 10ml / min, dropwise for a total of 6 hours, and the first stage reaction is carried out, and the reaction degree is controlled to be about 80%.

[0050] Add 800g of styrene and 10g of dibenzoyl peroxide into 1500g of water containing 0.5g of hydroxypropyl cellulose and 4.0g of Triton X-405, mix and emulsify, adjust the temperature of the reaction kettle to 50°C, and add all the ingredients dropwise within 2 hours T...

Embodiment 2

[0054] In a 5-liter reactor, 60 g of pre-prepared monodisperse swellable polystyrene particles (seeds), with a particle size of 1.5 μm and a CV of 2.8, were added to 1300 g of deionized water containing 1 g of hydroxypropyl cellulose; Stir and heat to 85°C at a speed of 150 rpm.

[0055] After mixing 800g styrene with 10g dibenzoyl peroxide, add 1500g water containing 0.5g KI, 0.5g hydroxypropyl cellulose and 4.0g Triton X-405, emulsify after mixing, at 85°C at an increasing rate Added into the aqueous solution, for example, the initial rate is 1ml / min, the final rate is 10ml / min, dropwise for a total of 6 hours, to carry out the first stage reaction, the reaction degree is controlled to be about 80%.

[0056] Add 800g of styrene and 10g of dibenzoyl peroxide into 1500g of water containing 0.5g of hydroxypropyl cellulose and 4.0g of Triton X-405, mix and emulsify, adjust the temperature of the reaction kettle to 50°C, and add all the ingredients dropwise within 2 hours The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com