Excavation tooth installation assembly and method

a technology for installing assembly and excavation teeth, which is applied in the direction of soil-shifting machines/dredgers, construction, etc., can solve the problems of tooth loss, tooth is no longer serviceable, and has to be replaced, so as to limit upward movement of pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

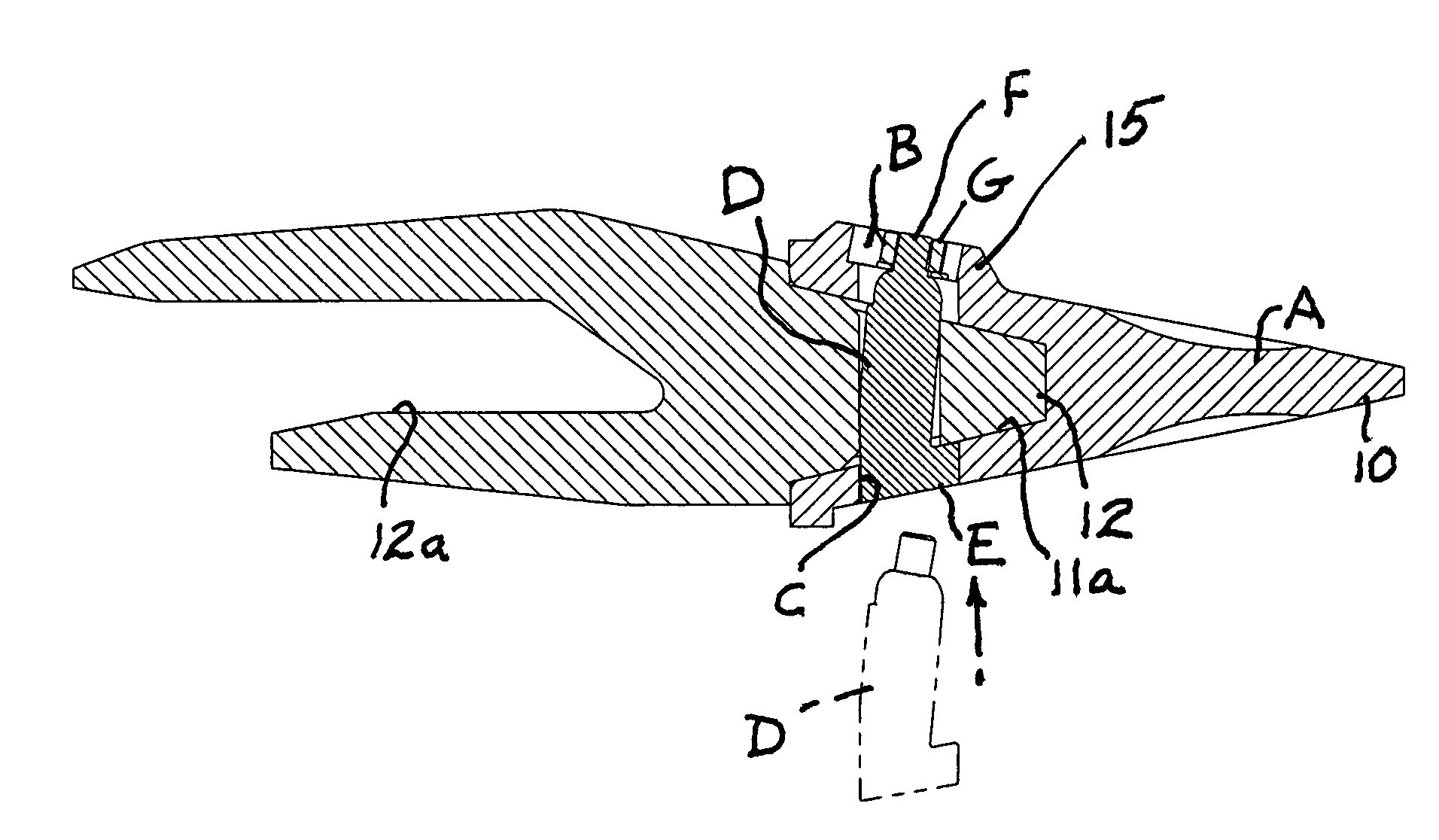

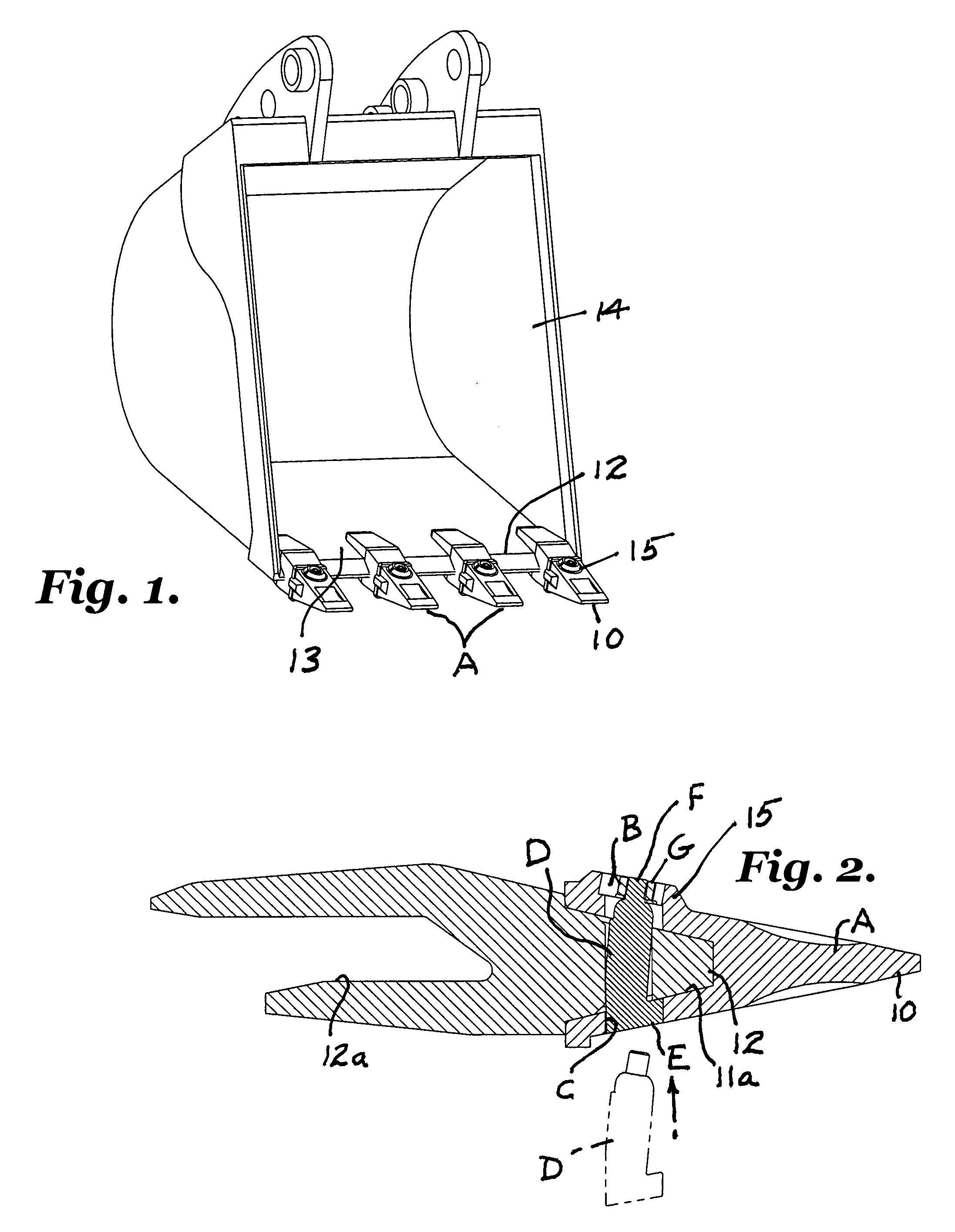

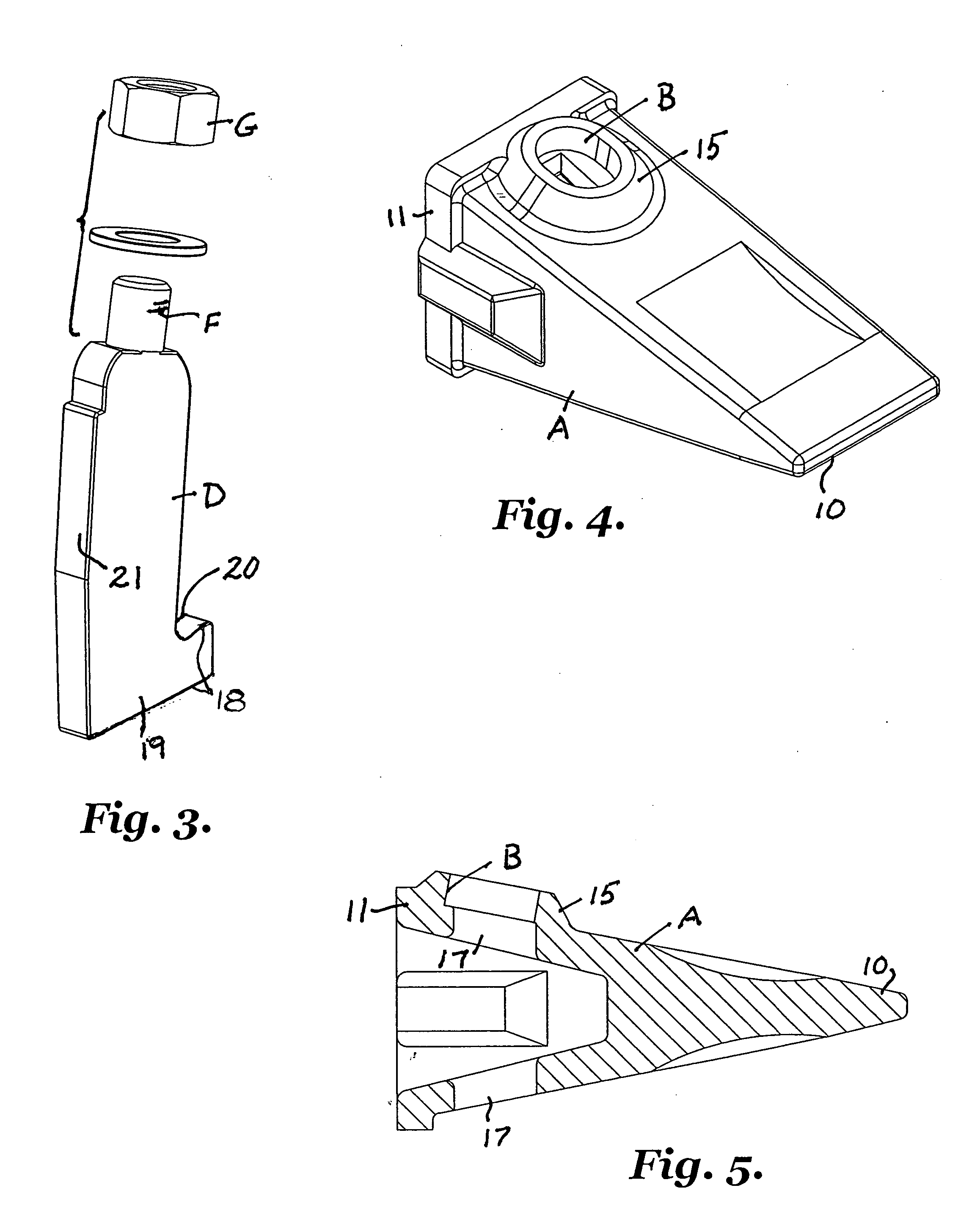

[0024] The drawings illustrate an excavation tooth and fastener assembly and method of excavation installing teeth on an adapter secured to a leading edge of an earth-moving implement. An excavation tooth A has a tooth point on one end and a tooth base at the other end configured for reception upon the adapter. An upper recess B in the tooth base is accessible from an exterior of the tooth base. A lower recess C in the tooth base opposite the upper recess is also accessible from an exterior of the tooth base.

[0025] An elongated retaining pin D has a stop member E to limit the extent to which the pin enters a vertical opening in the adapter during installation. An upright threaded shank F carried by one end of the retaining pin is configured for engagement by a compatible fastener G so that, after the retaining pin is inserted through the adapter into the upper and lower recesses in the tooth base and secured by the fastener, a new tooth is fixed upon the adapter.

[0026] The method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com