Precious stone cut and method of making

a precious stone and cut technology, applied in the field of cutting precious stones, can solve the problems of requiring extraordinary loss of rough diamond material, limited ability to significantly return white light, and loss of light through the bottom of the diamond to create dead zones, etc., and achieve the effect of increasing scintillation, brilliance, and dispersion of ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

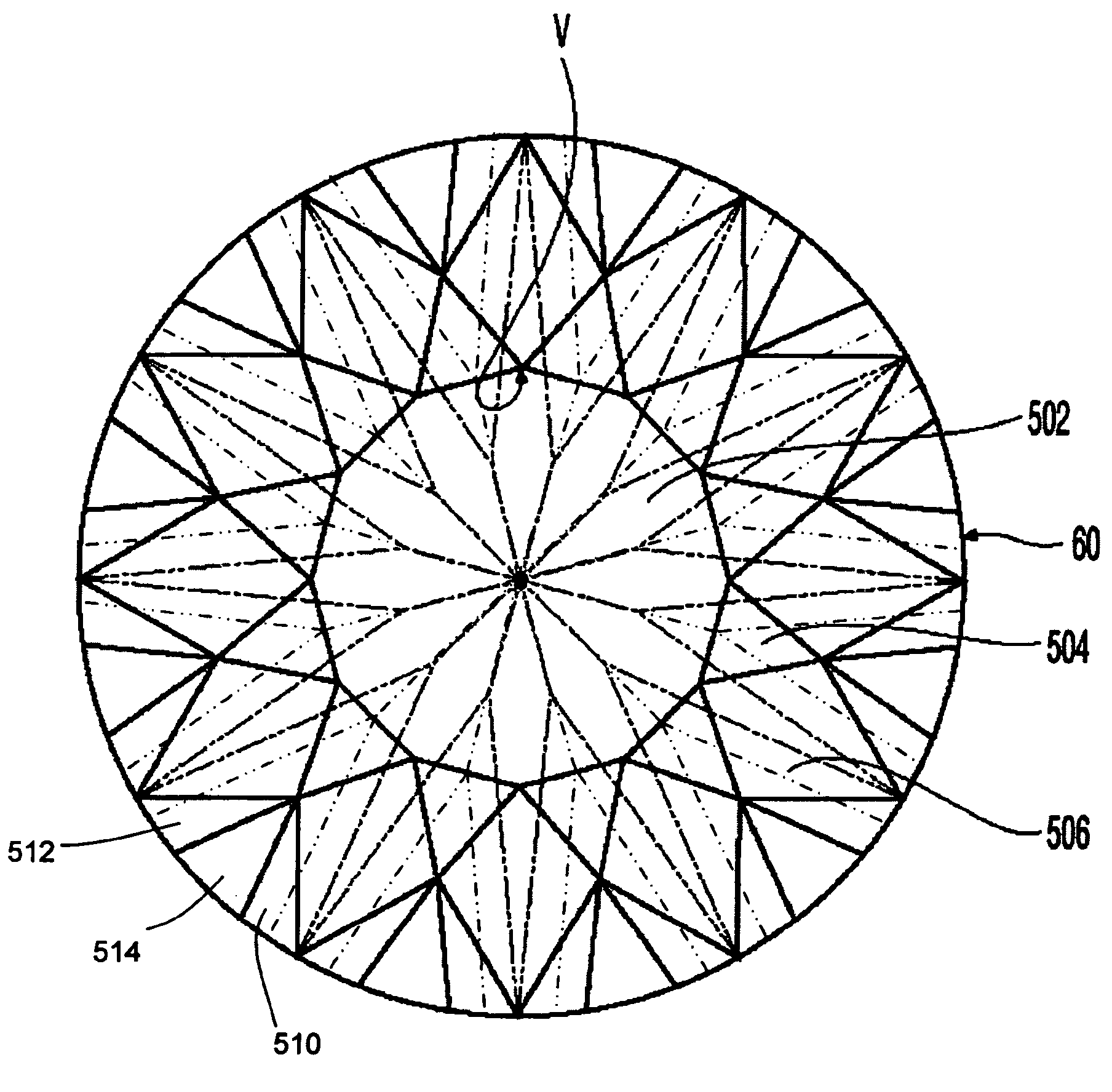

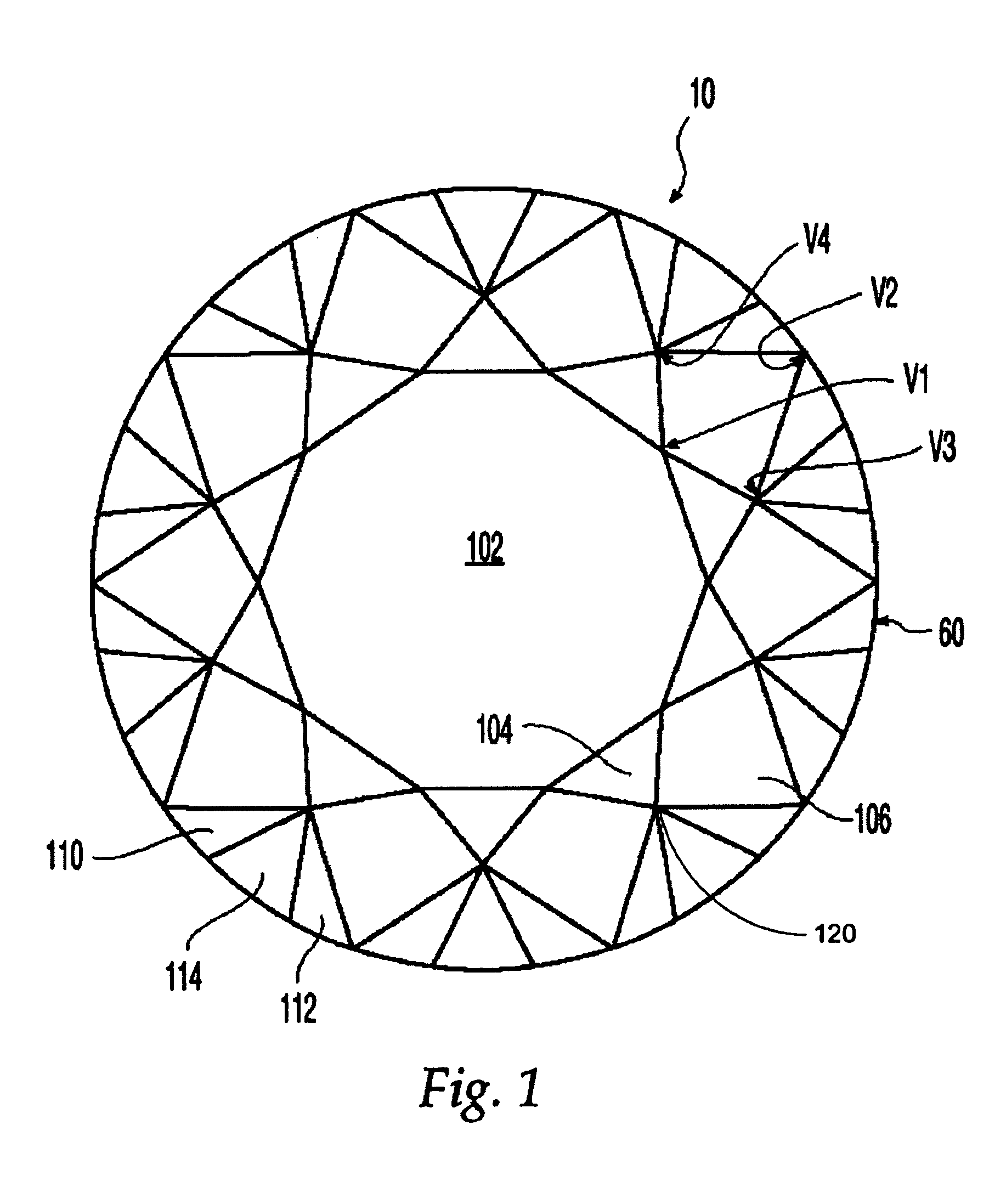

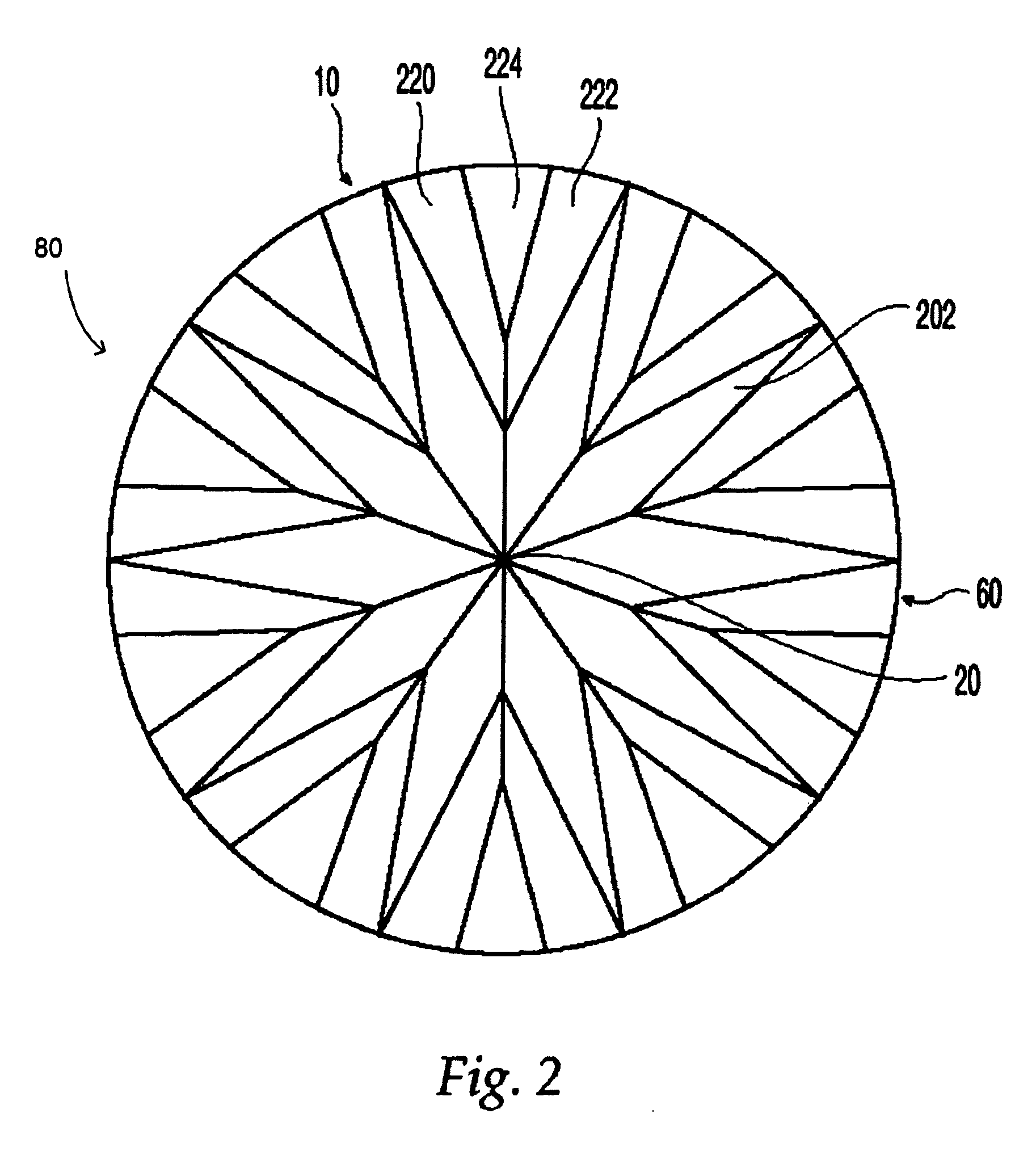

[0021] According to FIGS. 1-3, stone 10, such as a diamond, cut according to an embodiment of the present invention, is generally similar to a brilliant-cut diamond. Stone 10 has a generally round shape, when viewed from the top downward or bottom upward, and a generally pyramidal shape when viewed from the side. Stone 10 generally has girdle 60 defining the outer edge and widest portion of stone 10 in a top downward or bottom upward view; crown 40 defining the upper portion above girdle 60; pavilion 80 defining the lower portion below girdle 60; and culet 20 defining the lowest portion of pavilion 80. For purposes of explanation, features of stone 10 will be referenced with respect to central axis 12 that extends from culet 20 (FIG. 3), at a lower portion of stone 10, through the center of table 102, as represented by the dashed line 12 of FIG. 3. Furthermore, the outer edge of stone 10, girdle 60, will be referred to as the periphery of stone 10.

[0022]FIG. 1 shows a top view of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com