Light source structure, backlight module and display device

A technology of backlight module and optical structure, applied in the direction of light source, flat light source, lighting device, etc., can solve the problems of uneven light mixing, weak light intensity, and high light intensity, achieve uniform light, reduce contrast, and improve brilliance degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

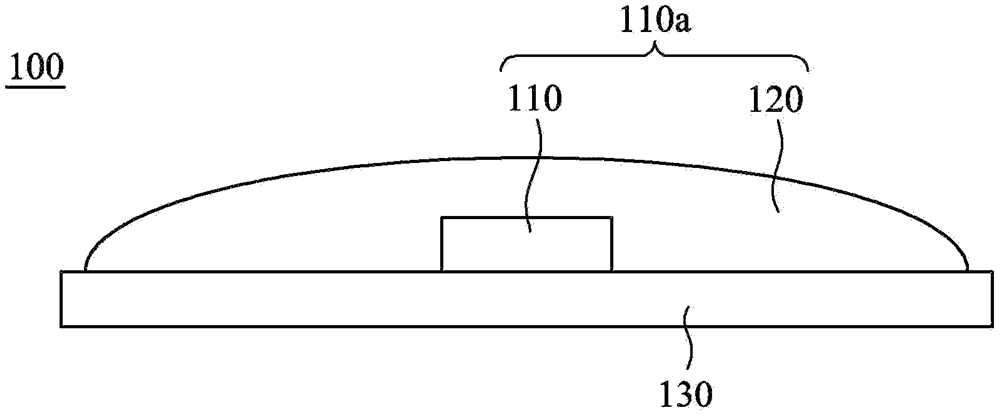

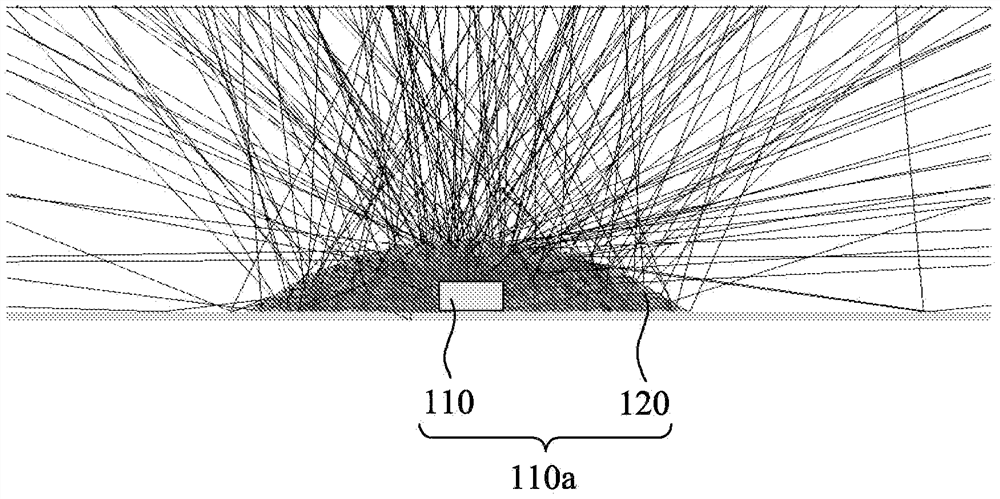

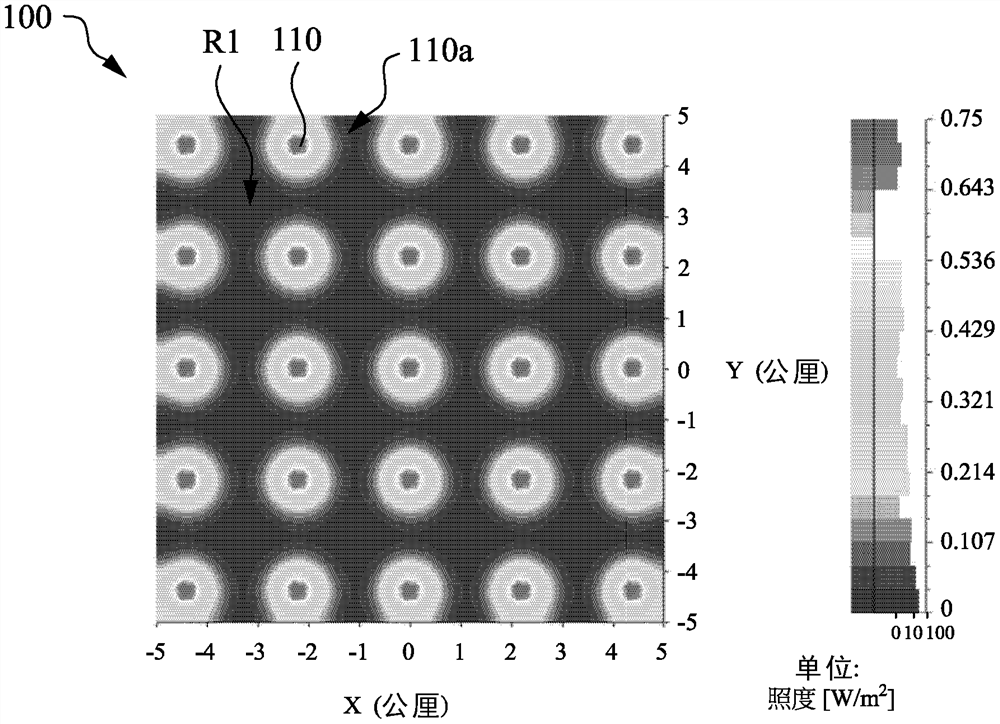

[0038] Please also refer to Figure 4 and Figure 5 ,in Figure 4 is a schematic diagram of a device illustrating a structure of a light source according to an embodiment of the present invention, Figure 5 It is a partial side view of a device illustrating a light source structure according to an embodiment of the present invention. The light source structure 300 of this embodiment mainly includes a substrate 310 , a plurality of light emitting units 320 and a plurality of packaging structures 330 . Wherein, the light emitting units 320 are arranged in an array on the substrate 310 , and each light emitting unit 320 has a central optical axis S1 perpendicular to the substrate 310 . In this embodiment, the central optical axis S1 is a normal line passing through the center of the light emitting surface of the light emitting unit 320 . Such as Figure 4 As shown, in one embodiment, the light emitting units 320 may be arranged in an array along the first direction D1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com