Light conducting plate and manufacturing method thereof

A manufacturing method and technology of a light guide plate, applied in the fields of optics, optomechanical equipment, nonlinear optics, etc., can solve the problem of low luminance of the light guide plate, and achieve the goal of improving light utilization, reducing light loss, and increasing luminance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

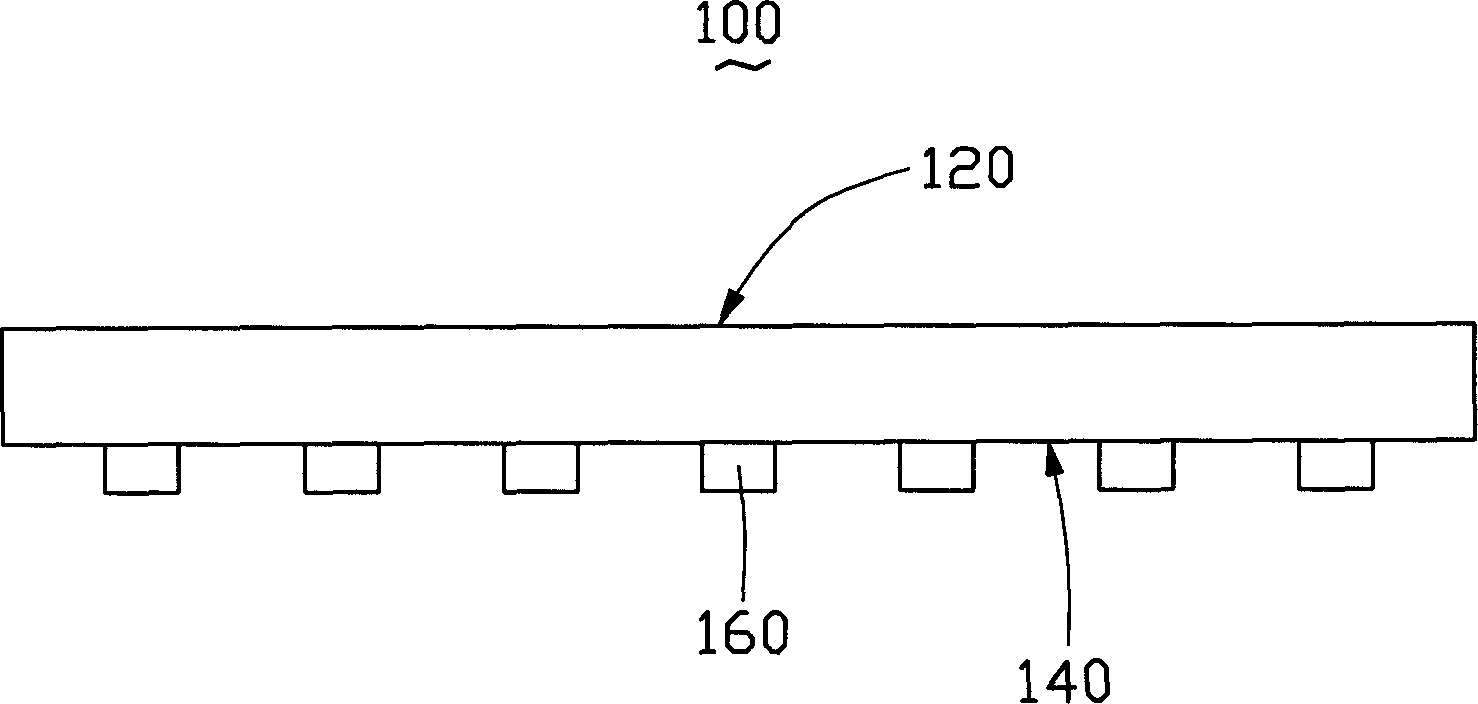

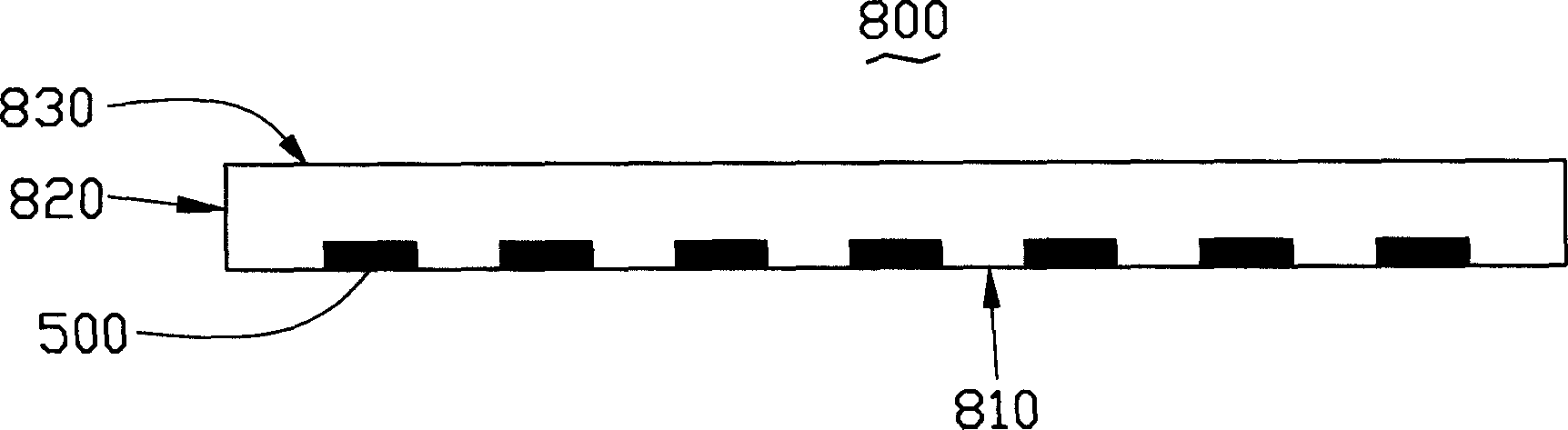

[0021] see figure 2 , the light guide plate 800 of the present invention includes at least a light incident surface 820 , a light output surface 830 and a bottom surface 810 . Wherein, the light-emitting surface 830 is opposite to the bottom surface 810 , and the metal layer 500 with a cylindrical fine structure is embedded in the bottom surface 810 . Since the refractive index of the metal layer 500 is different from that of the material of the light guide plate 800, the total reflection condition of the light is destroyed, and the light is effectively reflected to the light-emitting surface 830 of the light guide plate, which can reduce light loss, make the light output uniform, and increase the brightness.

[0022] see Figure 3 to Figure 10 , is the manufacturing method of the light guide plate of the present invention.

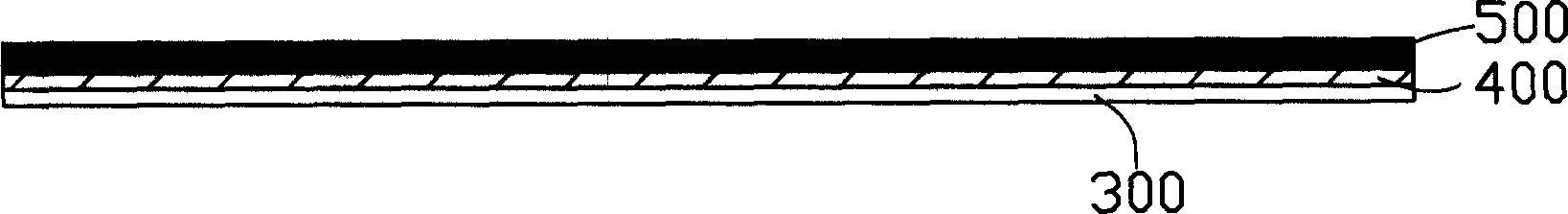

[0023] see image 3 , provide a base 300, the base 300 is made of polymer material, such as polyethylene terephthalate (Polyethylene Terephthalate, P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com