Assembled floating cover for a storage tank

a floating cover and storage tank technology, applied in the direction of transportation and packaging, packaging, large containers, etc., can solve the problems of inconvenient mounting, difficult fabrication, and complex construction, and achieve the effect of reducing maintenance time, increasing the amount of oil to be reserved, and lightening weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

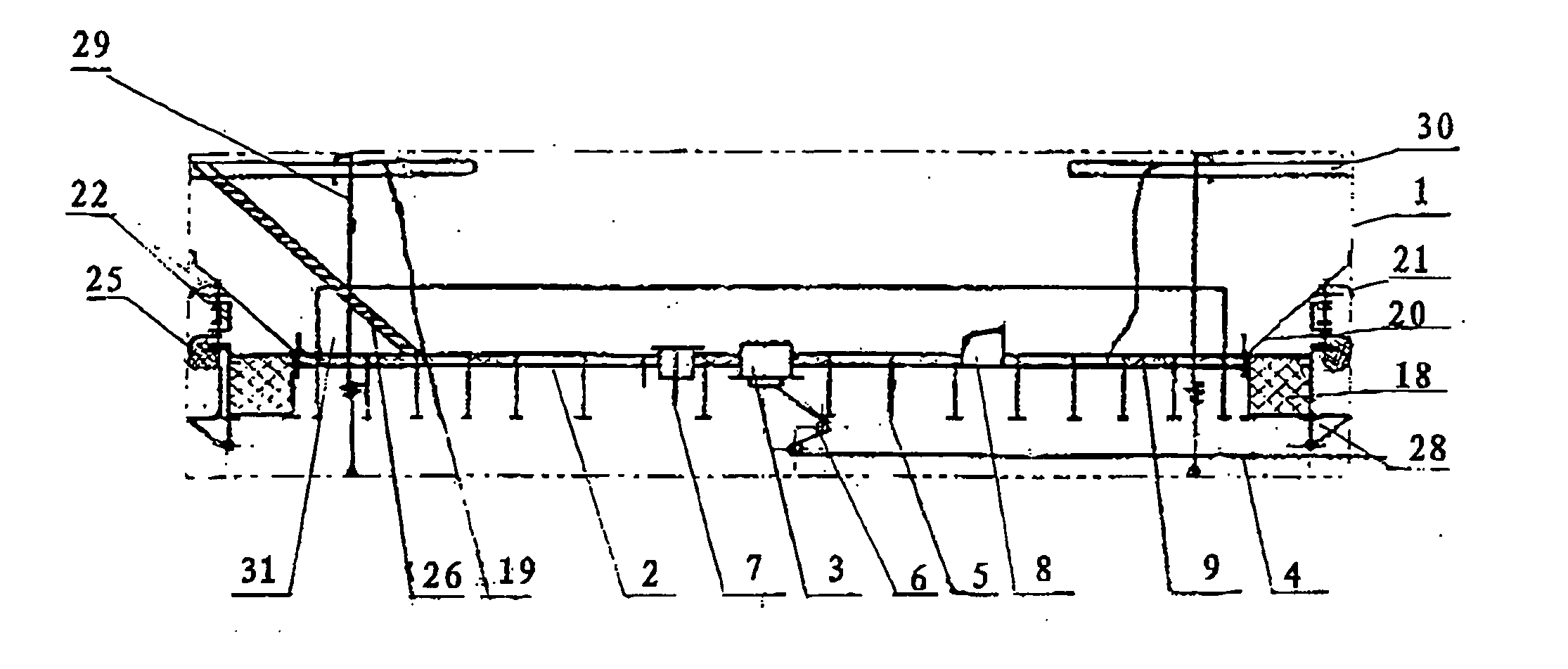

[0008] It can be seen from FIG. 1, within the body (1) of reservoir, there mounts an outer floating disc (2). At its central position, there mounts a central water draining funnel (3) which is connected with a lower water draining pipe (4). At the bottom of outer floating disc (2), there mount several supporting legs (5), and an emergency water discharging valve (6). At the central position of the disc, there further mounts a safety venting valve (7). On the upper face of outer floating disc (2), there provides a manhole (8) for inspection and repair. On the body of the floater, there further mounts a fire-extinguishing foam protecting plate (31). And over the top of body (1) of the reservoir, a supporting frame (30) is installed.

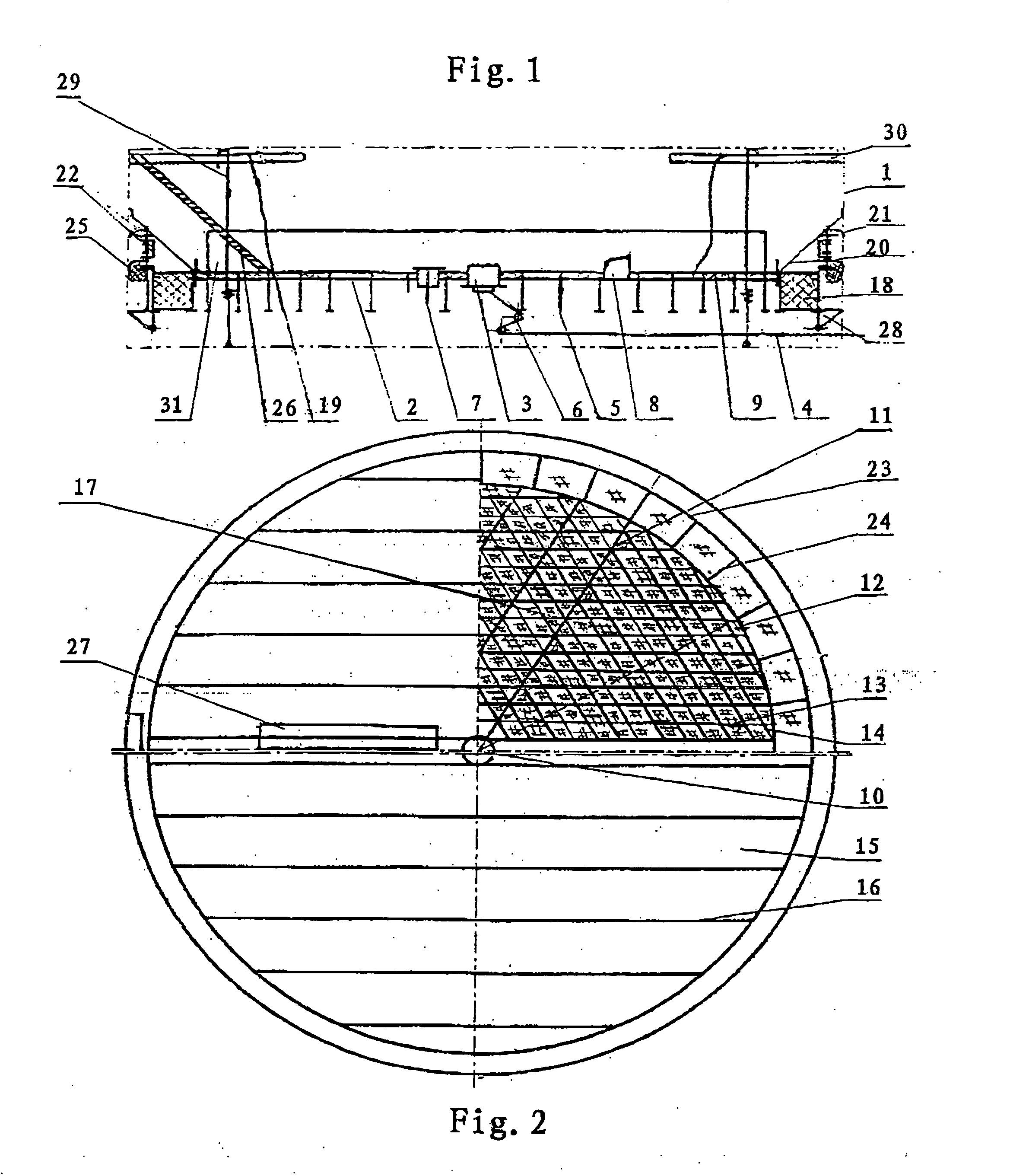

[0009] It can be seen from FIG. 2, the components with I-shaped profile are made from steel plate and joined by bolts into a radiant skeleton structure, the floaters (9) made from oil resistant hard poly-urethane plastics are light and are laid full of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com