Apparatus and method for measuring the weight of an occupant in a vehicle

a technology for measuring the weight of an occupant and a vehicle seat, which is applied in the direction of instruments, apparatus for force/torque/work measurement, tractors, etc., can solve the problems of not providing an accurate measurement of the weight of the occupant, the sensor the seat and any sensor coupled to the seat is subject to error-inducing loads, so as to prevent inaccurate readings of the occupant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0034] Several embodiments of the present invention will be described below. Some features of each embodiment are similar and are therefore given similar reference numbers. For example, a feature labeled as element “9” in one embodiment, may be labeled as element “109,”“209,” etc. in other embodiments. Although some features may share a common number, it does not mean that the features are identical. Rather, it indicates that these features are similarly situated, share structural similarities, or perform similar functions. The features that are common to one or more embodiments will generally only be described once. Thus, it will be described in the first embodiment in which it appears. The descriptions of common elements will generally not be repeated in subsequent embodiments. Thus, reference to previous embodiments may be required in some instances to fully understand certain embodiments.

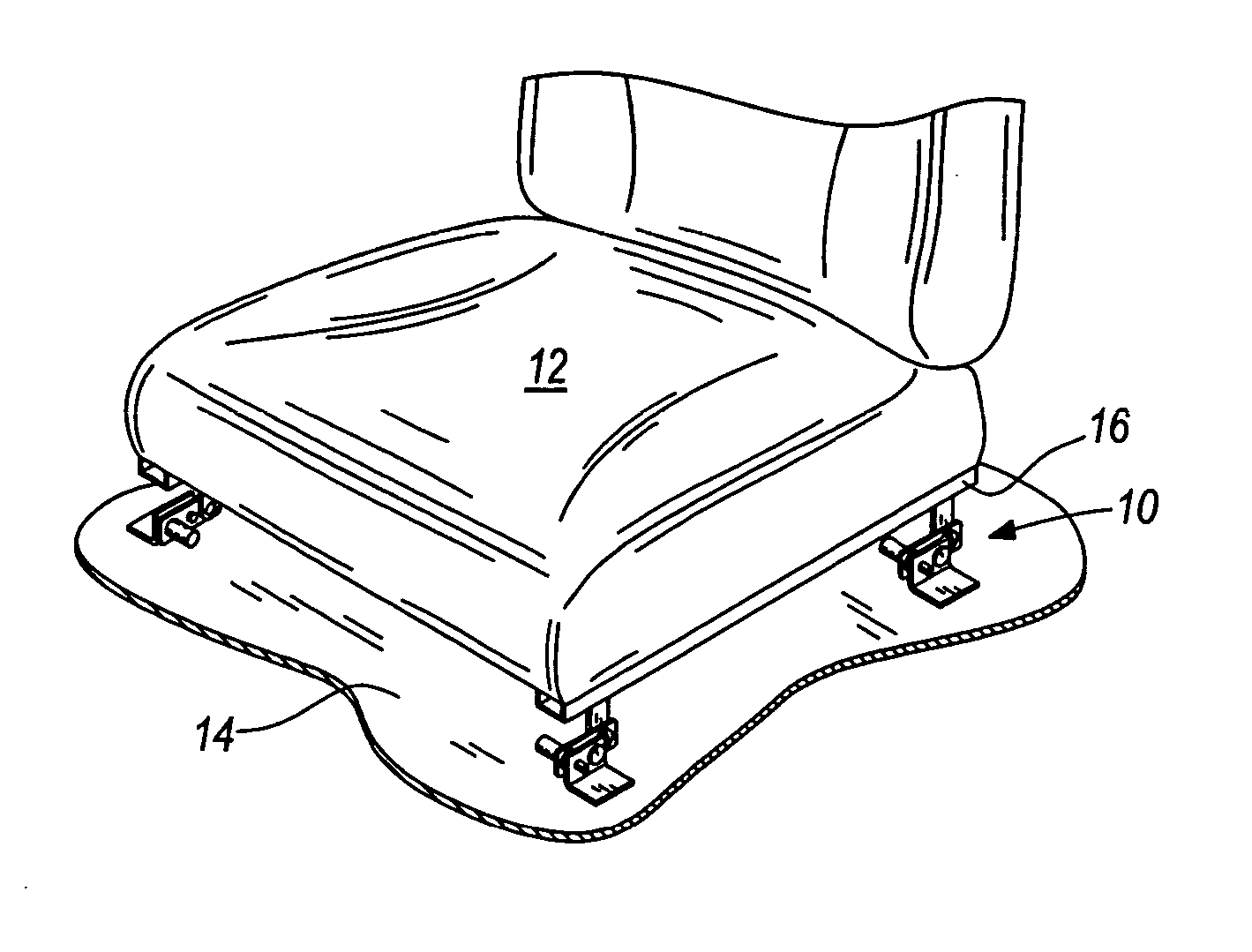

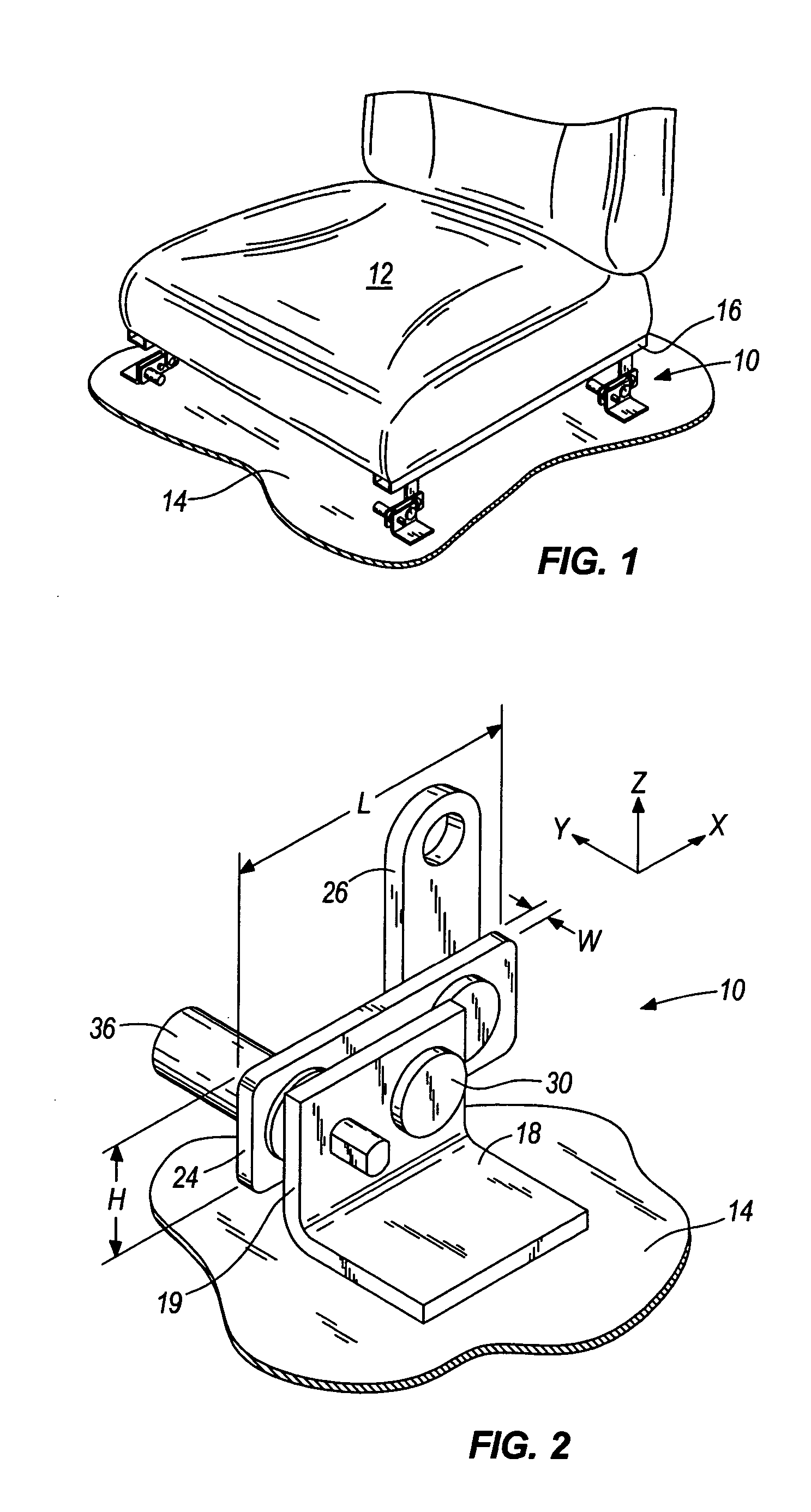

[0035]FIG. 1 illustrates a plurality of brackets 10 positioned below a seat 12 to support an...

sixth embodiment

[0063] By closing off the bifurcated portion 527 at both ends, the linkage 526 can be connected in a different manner with the As illustrated in FIG. 12, the linkage 527 is connected to the closed end of the bifurcated portion 527 with a fastener. Unlike the previous embodiment, the illustrated fastener of this embodiment has an axis that is substantially normal to the axis of the pivot 530. Such an arrangement can help reduce y-direction forces and moments about the x-axis (see FIG. 2) transferred to the lever 524. Consequently, this reduces the number of extraneous forces that need to be filtered by the remainder of the apparatus. This arrangement between the lever and the linkage can be utilized in other embodiments disclosed herein.

[0064] Although a pivot having a single axis is illustrated in the sixth embodiment, other connections between the linkage 526 and the lever 524 can be utilized. For example, a ball joint can be used in place of the pivot. A ball joint can prevent mo...

fourth embodiment

[0066] Each lever 624 is substantially identical and has a three portions: a first portion 661 located near a first corner of the seat, a second portion 662 located near a second corner of the seat, and a third portion 663 connecting the two portions 661, 662 together. The first and second portions 661, 662 are substantially identical. Therefore, only one will be discussed. The first portion 661 is substantially similar to the lever 324 of the Specifically, the first portion is split between a first segment 627 that is bifurcated and a second segment 628 adjacent the bifurcated portion. Like the previous embodiments, the pivot 630 and the seat are coupled to the first portion 661 along the bifurcated segment 627. However, unlike the previous embodiments, the third portion 663 of the lever 624 stretches underneath the seat from the first portion 661 located adjacent one side of the seat to the second portion 662 located adjacent an opposite side of the seat. Additionally, a tab 664 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com