Compression coil spring device having discontinuous support structure

a coil spring and support structure technology, applied in the direction of springs/dampers, wound springs, mechanical equipment, etc., can solve the problems of increasing the spring load, reducing the number of effective turns of the coil spring, and the close wound turn and ground end are not effective in producing spring force, so as to minimize the spring force and minimize the variation in the spring property , the effect of friction resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

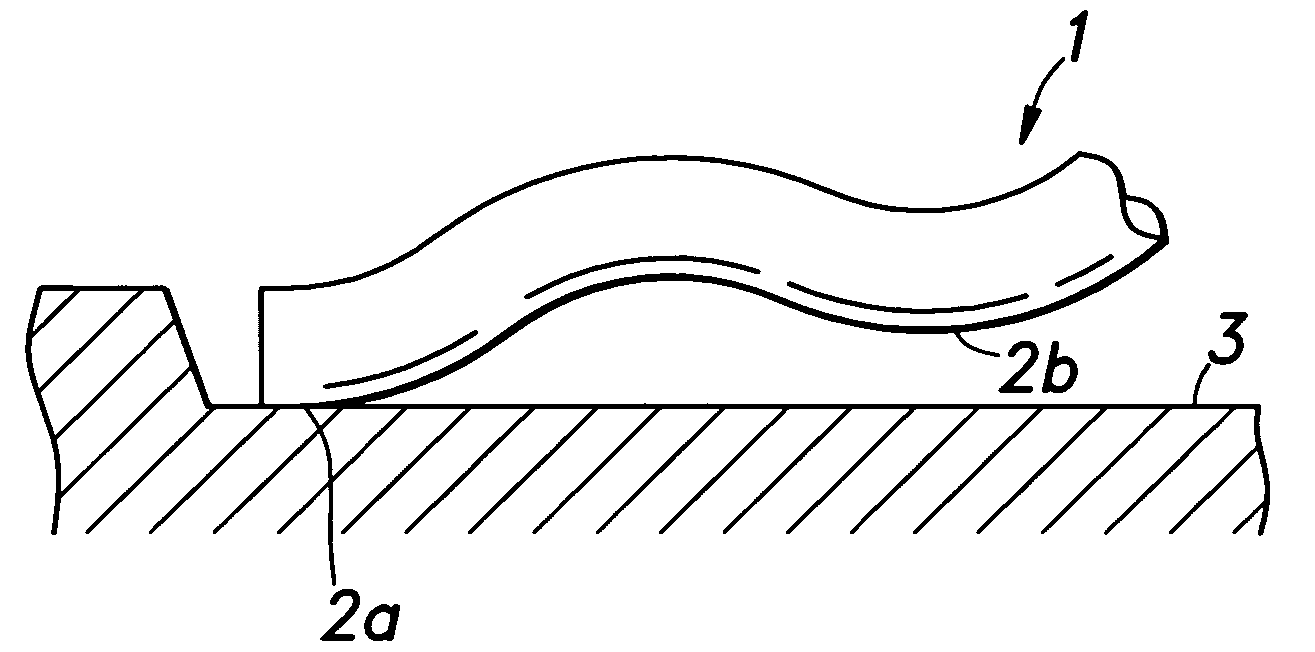

[0030]FIG. 1 shows an exemplary end turn of a coil spring embodying the present invention. The end turn 1 of this coil spring consists of an open end coil turn, and is provided with a wavy shape as represented by a plurality of bends 2a and 2b. As a result, the contact between the end turn 1 and a spring seat 3 is effected substantially as a point contact, instead of a line contact. According to the prior art, the length of contact between the end turn and the spring seat increased with the increase in the load. However, according to the illustrated embodiment, the part of the coil wire located between the two bends 2a and 2b is spaced from the spring seat 3 and thereby remains to be effective as a part of effective turns during the time the load is increased from a value by which only one of the bends 2a is in contact with the spring seat 3 to a value by which the next bend 2b is also brought into contact with the spring seat 3. In other words, because the contact position between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com