Ostomy appliance

a technology for ostomy and ossomy, which is applied in the field of ostomy appliances, can solve the problem of limitless reshaping of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

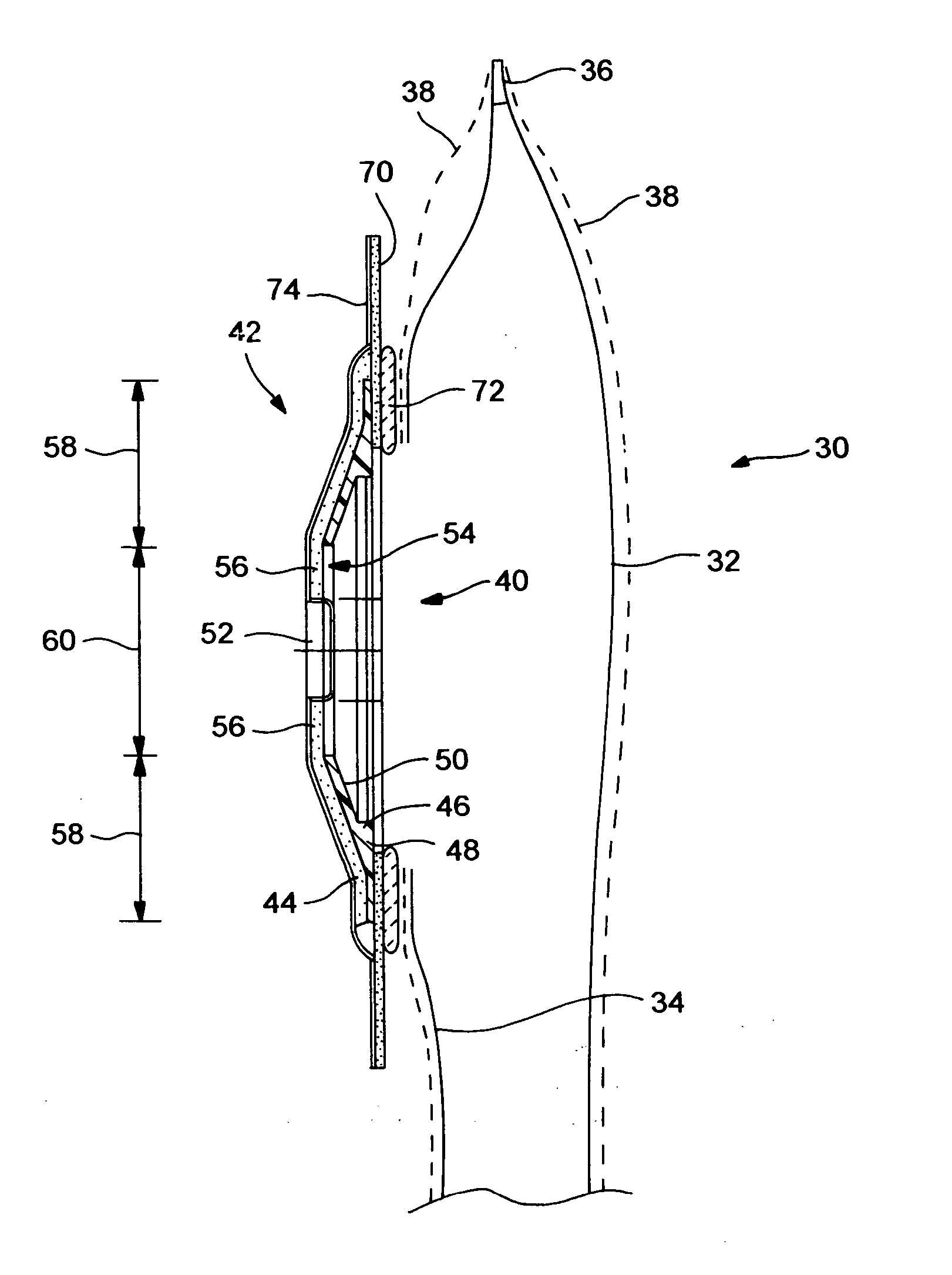

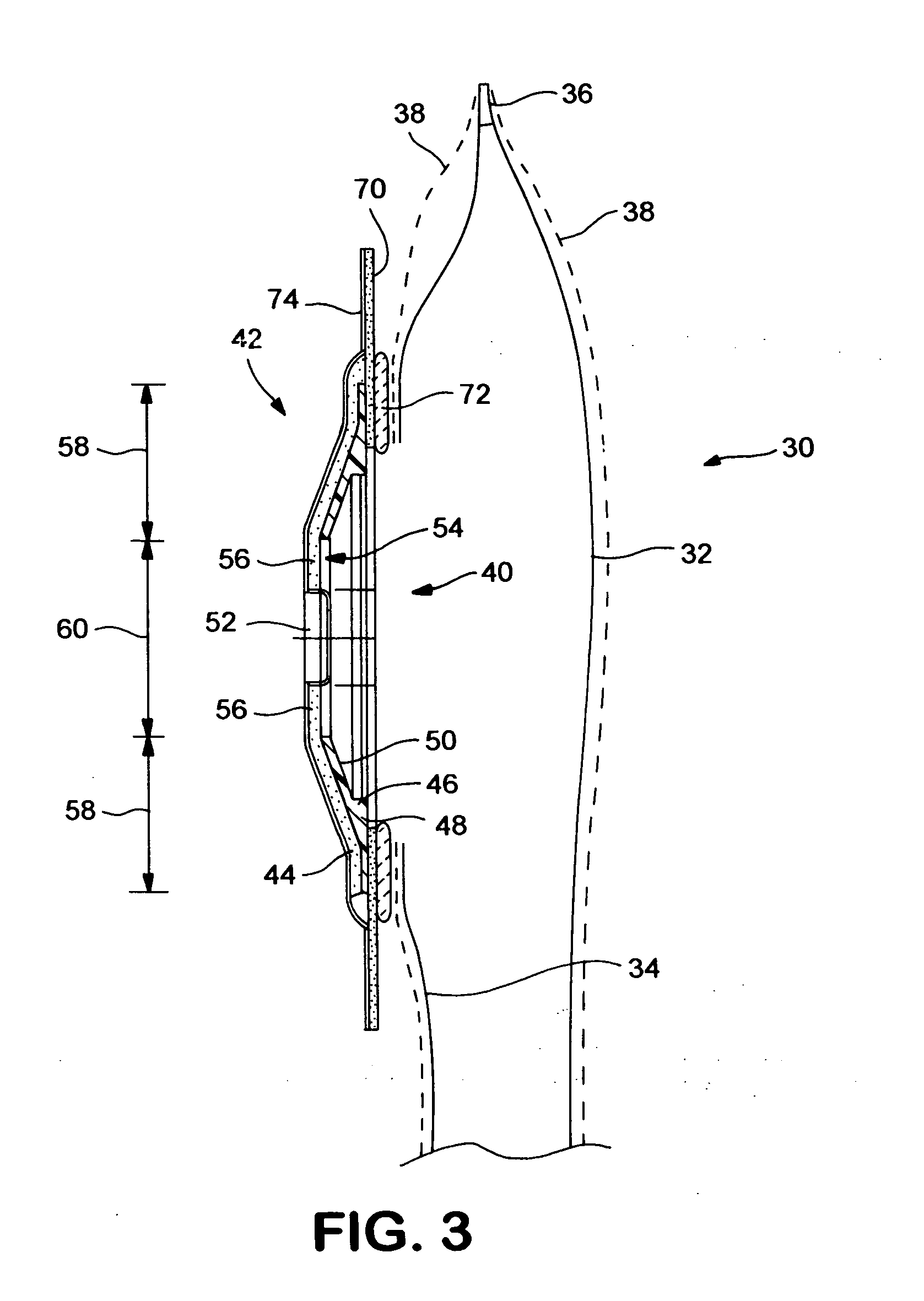

[0048] Referring to FIGS. 3-6, a first embodiment of the invention is illustrated in the form of a one-piece pouch 30. This application of a shapeable adhesive with a one-piece pouch is believed to be novel in one non-limiting aspect of the invention.

[0049] The pouch 30 comprises front and rear walls, 32 and 34 respectively, welded together around their periphery 36 to define a pouch envelope. The walls 32 and 34 are of a liquid and gas impermeable material, for example, a laminate of one or more layers of polyvinylethylene (PVE) and a barrier layer of polyvinyledine chloride (PVDC). A comfort layer 38 of a soft, cushioning material may be provided outside the front and rear walls 32 and 34, and secured in the weld at the periphery 36. Although not shown explicitly, the pouch 30 may be provided with a conventional filtered vent for allowing gases to vent through a deodorizing filter. The bottom of the pouch 30 may be closed, or it may be provided with a closable, drainage chute for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com