Airflow diverter for upright-type vacuum cleaner and upright-type vacuum cleaner having the same

a vacuum cleaner and airflow technology, applied in the field of upright-type vacuum cleaners, can solve the problems of cumbersome cleaning and unaddressed needs in the industry, and achieve the effect of improving the suction efficiency of reducing the distance between the vacuum generation device and the floor suction brush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinbelow, embodiments of an airflow diverter for an upright-type vacuum cleaner according to the present invention, and an upright-type vacuum cleaner equipped with such an airflow diverter, will be described in detail with reference to the accompanying drawings.

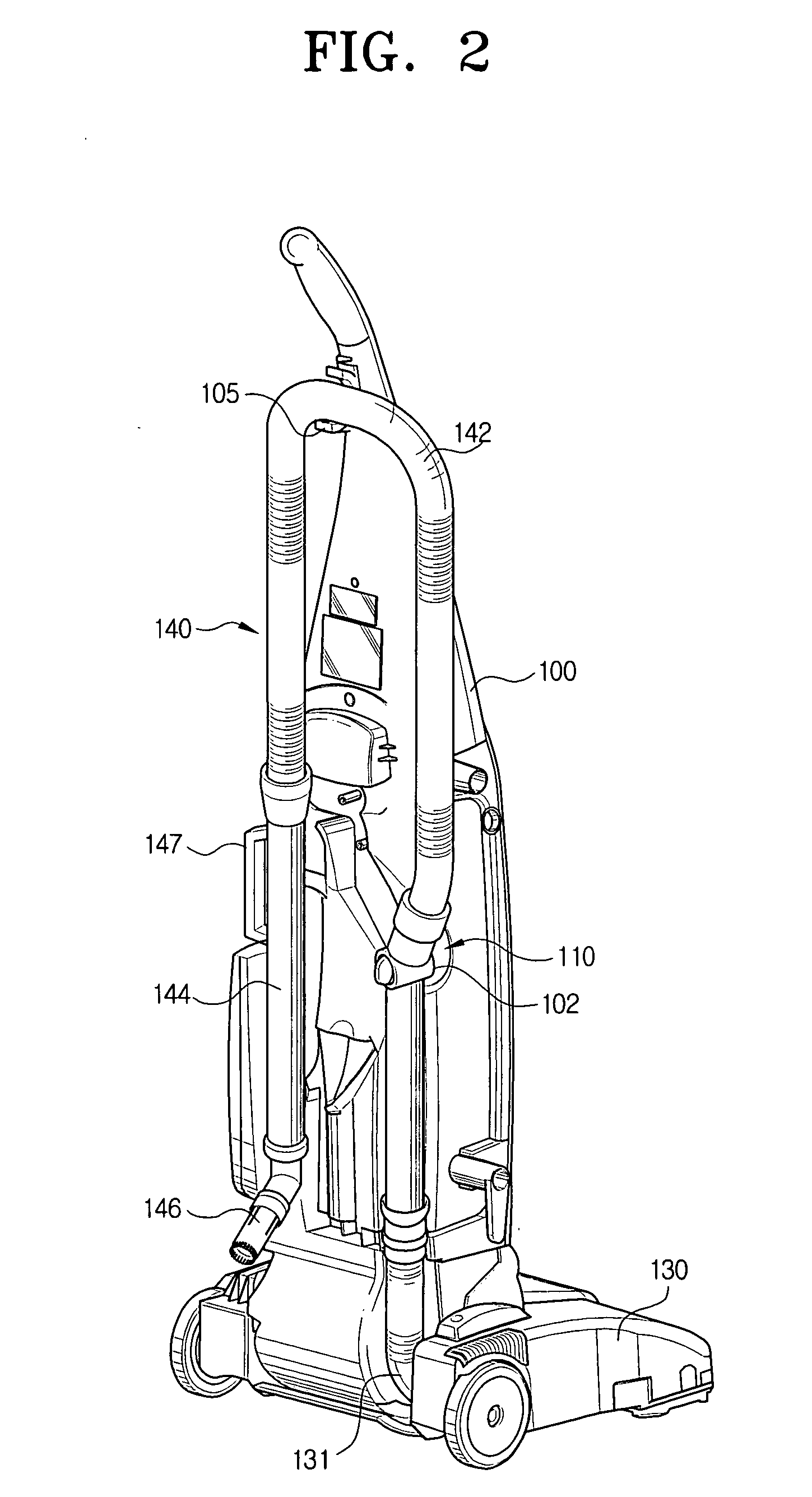

[0034] Referring to FIG. 2, the inventive upright-type vacuum cleaner comprises a cleaner body 100, an airflow diverter 110, a floor suction brush 130 and an auxiliary suction brush 140. The interior of the cleaner body 100 is divided into a dust collection chamber (not shown) at the upper part and a vacuum generation chamber (not shown) at the lower part. A dust filter or a cyclone dust collection device for filtering dust or various soils entrained in drawn-in air is removably installed in the dust collection chamber. The vacuum generation chamber is provided with a vacuum generation device for generating a suction force, wherein the vacuum generation device includes a fan (not shown) for generating the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com