Low/high temperature substrate holder to reduce edge rolloff and backside damage

a substrate and high temperature technology, applied in the field of substrate holders, can solve the problems of different reaction rate, non-uniform substrate temperature, and uneven substrate temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

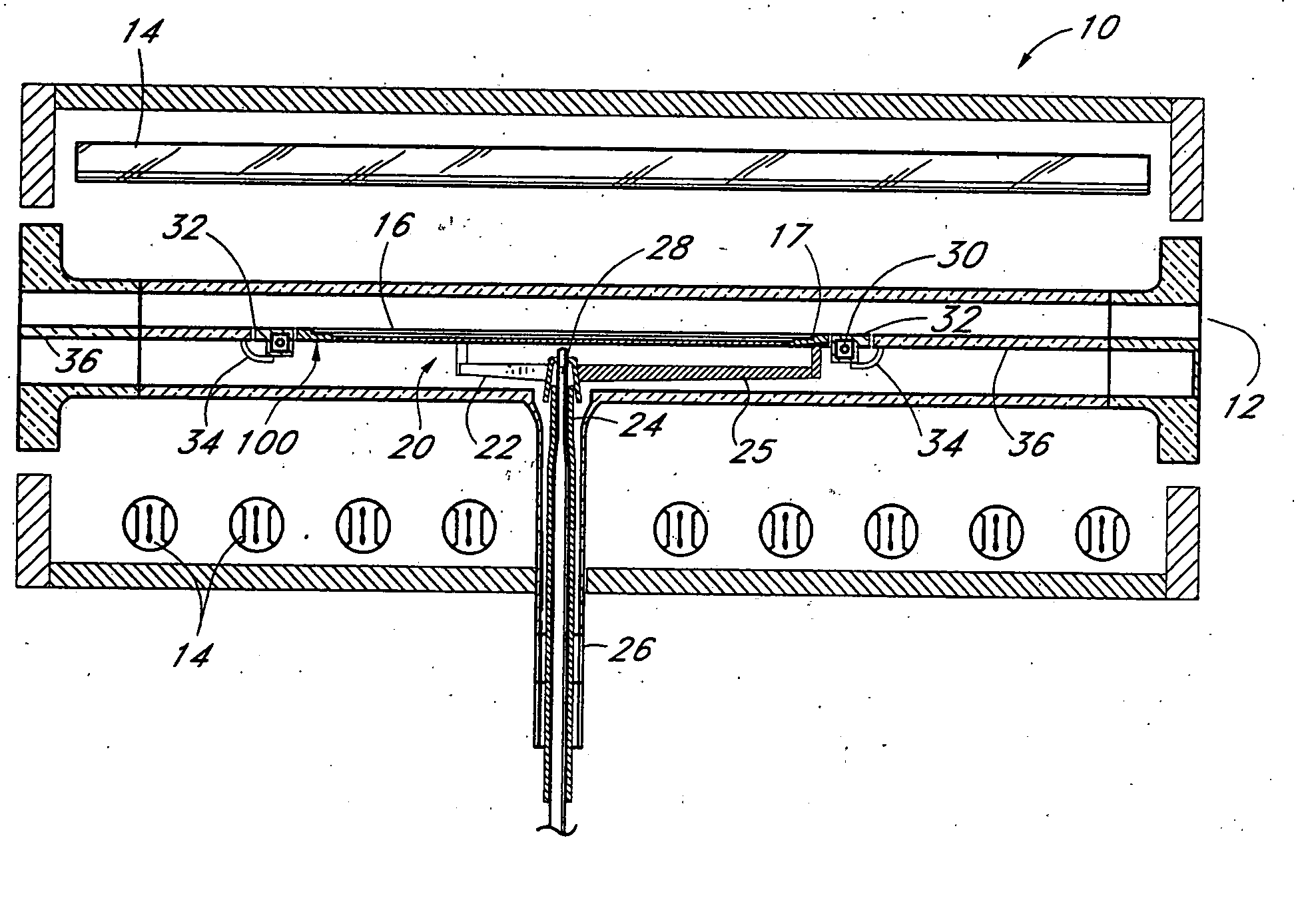

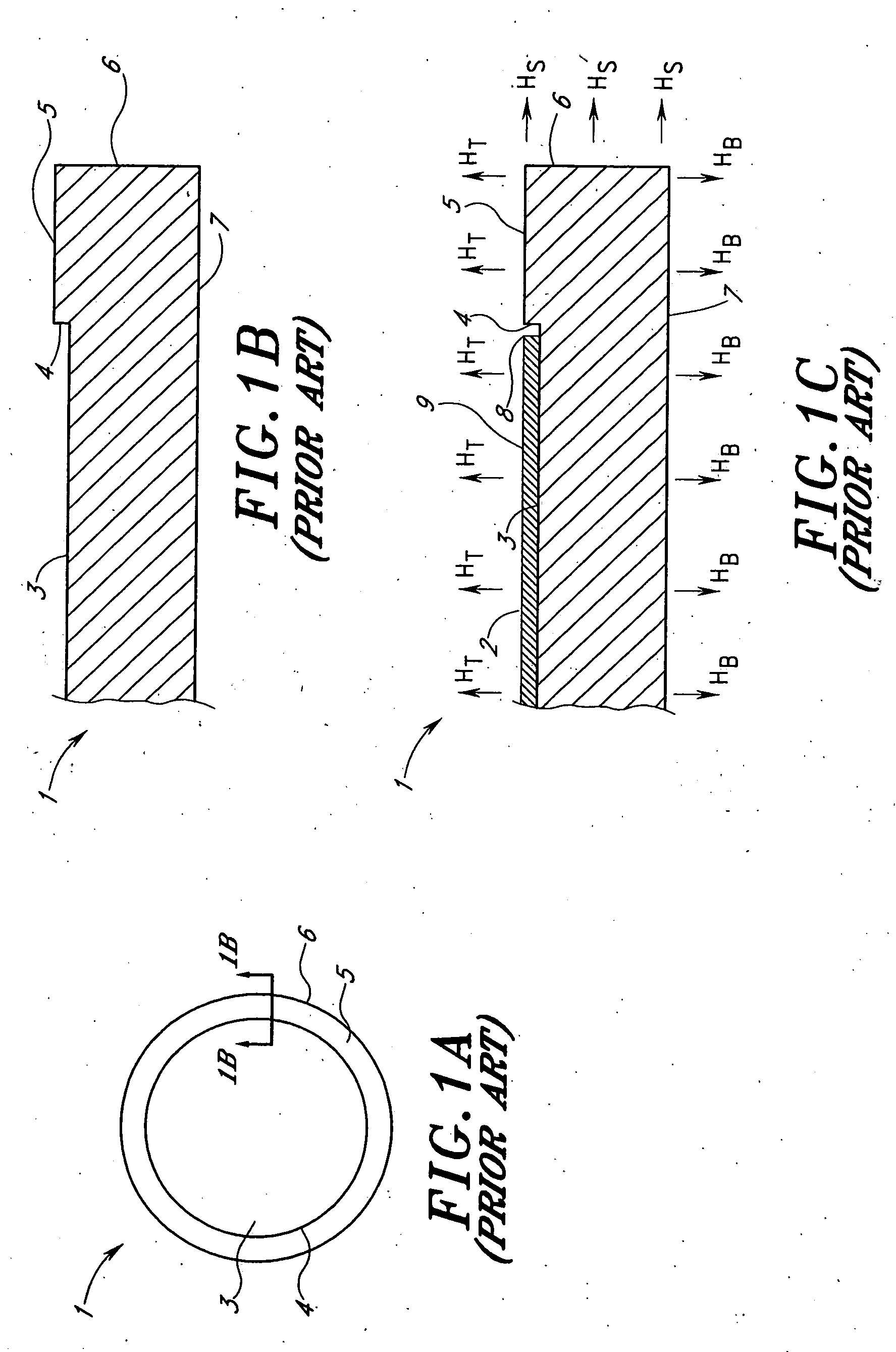

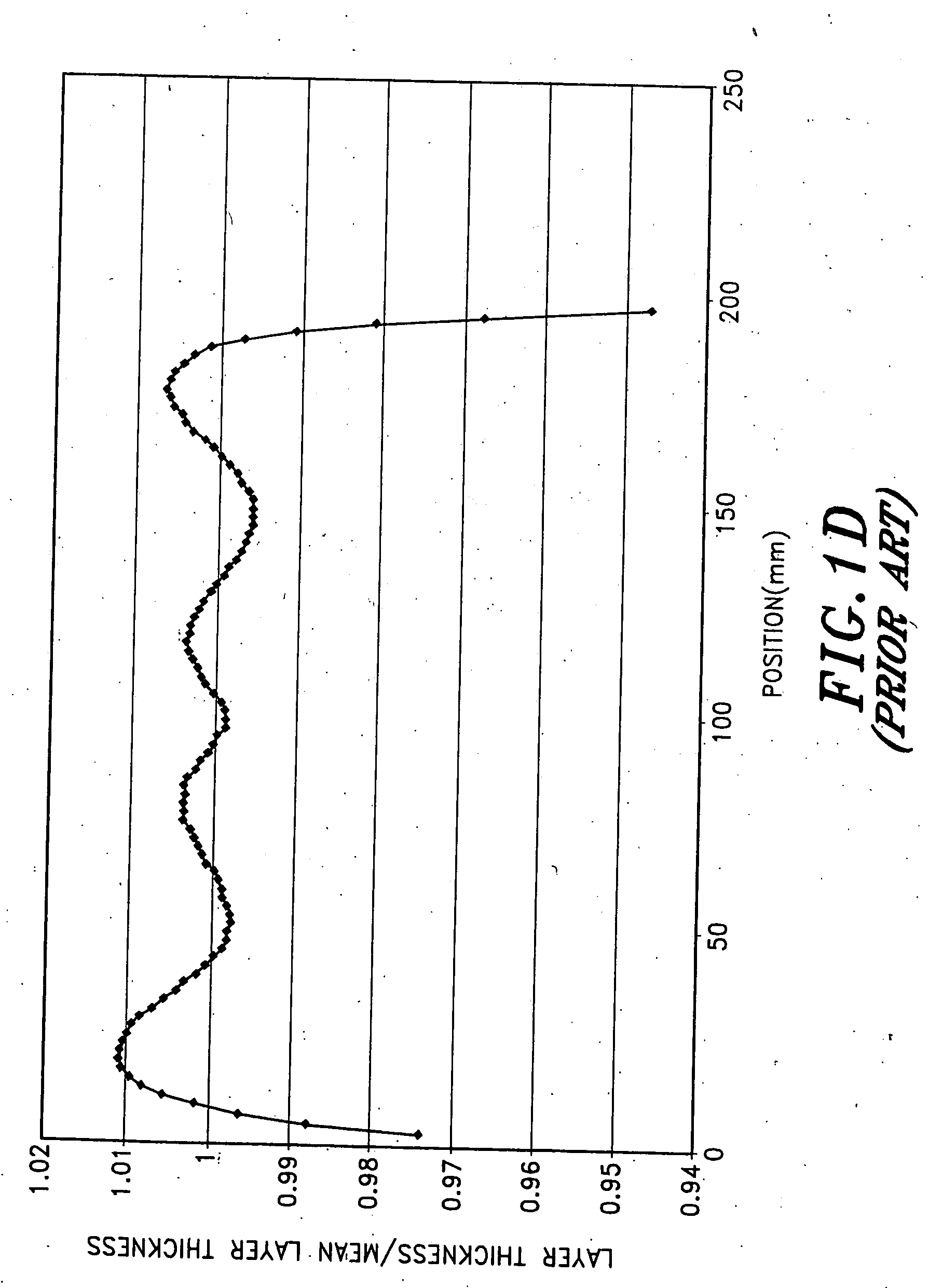

[0029] While the claimed invention is described in the context of CVD, it will be understood that the invention described herein is applicable to other types of thermal processing, including etching annealing, oxidation, nitridation, reduction and ALD. As noted above in the Background of the Invention section, processed substrates are typically characterized by an exclusion zone at the outer radial portion of each substrate, within which the deposited film has non-uniform qualities. This non-uniformity of the substrate is due in part to non-uniformity in temperature of the substrate holder upon which the substrate is supported. The outer radial portion of a typical substrate holder loses heat convectively at a greater rate than the remainder of the substrate holder. This disparity in the rate of heat loss is due to the outer radial portion of the substrate holder having a larger surface area over which heat loss can occur. The outer radial edge of the substrate holder also loses som...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com