Contact lens handling and inserting device and storage container

a technology for inserting devices and contact lenses, which is applied in the field of contact lens handling and inserting devices and storage containers, can solve the problems of introducing the possibility that the lens will become contaminated, affecting the use of the contact lens, and the user's grasping of the contact lens is much more difficul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

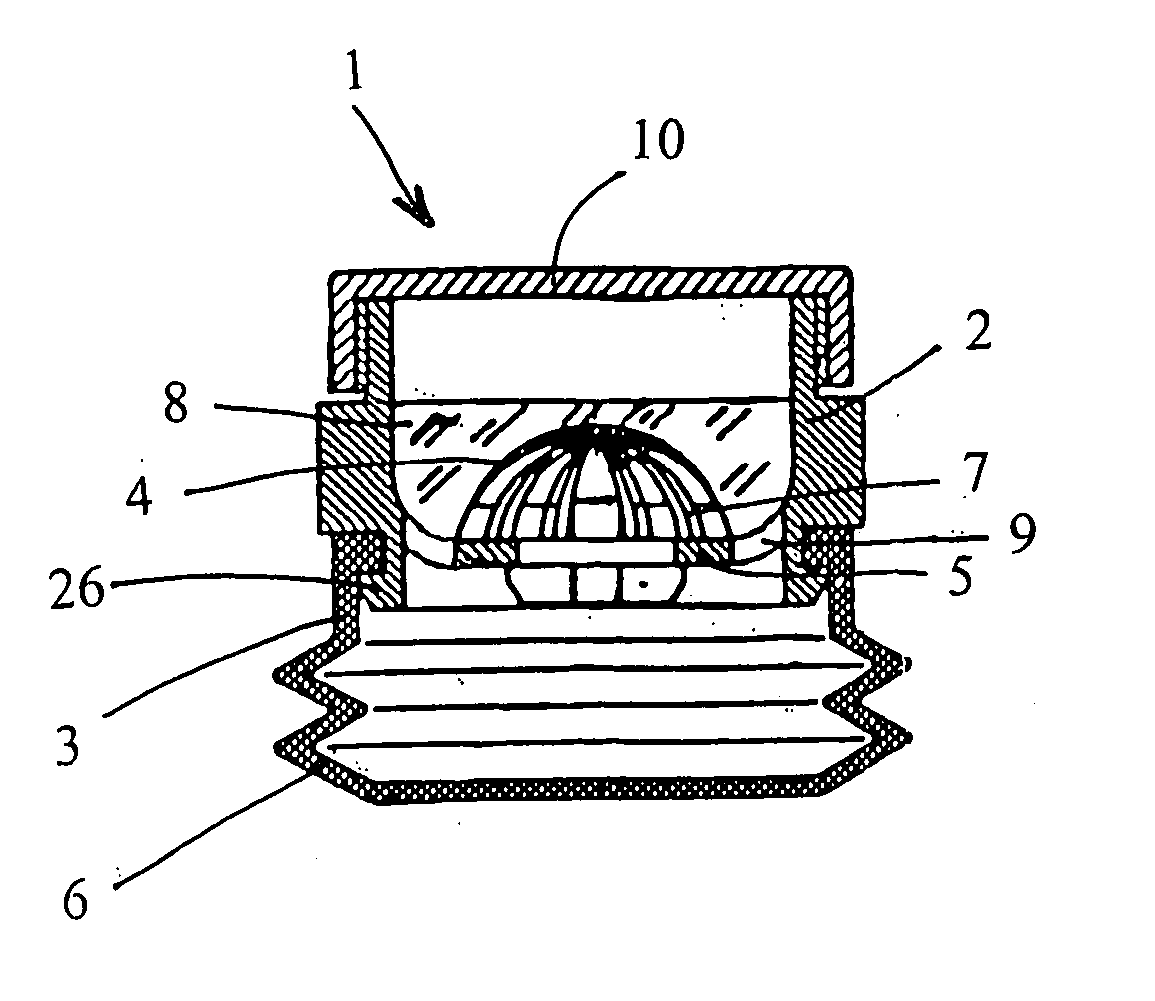

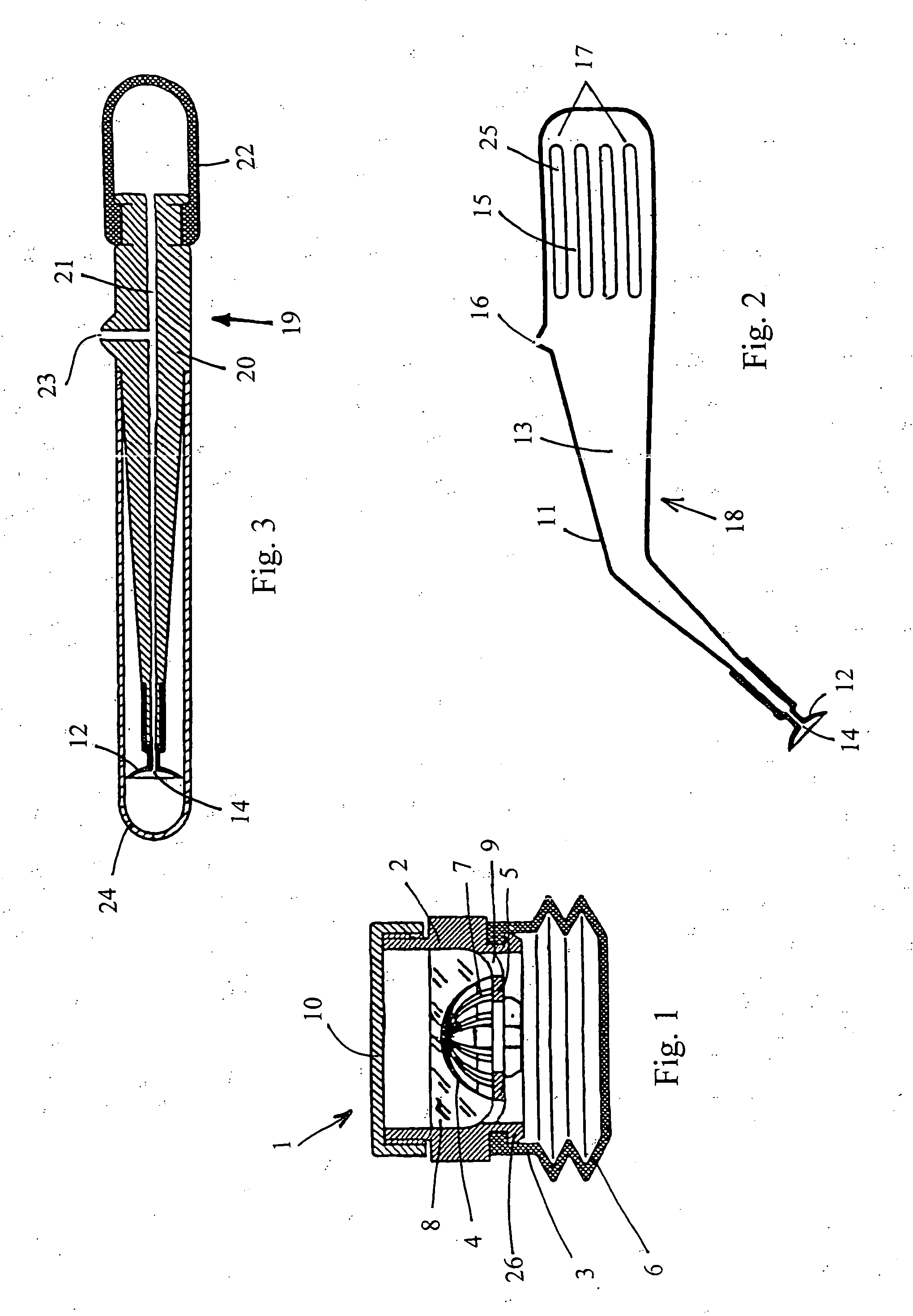

[0025] the inserting and handling device 18 as shown in FIG. 2 includes a main body which is hollow body 11. A suction cup 12 is located at a first end of the hollow body 11 and has an opening 14 that leads to and communicates with a hollow portion 13 of the hollow body 11. The suction cup is shown fitted onto one end of the hollow body 11. According to this embodiment of the inserting and handling device 18 of the present invention, the hollow body 11 has a deformable portion 15. This allows a user to create a vacuum at the suction cup 12 so as to permit the suction cup 12 to grasp an object such as a contact lens by deforming the deformable portion 15 of the hollow body 11 until air is discharged from the opening, and then applying a lesser force on the deformable portion 15 of the hollow body 11 such that a vacuum is formed in the hollow body 11. When a user places his finger over vacuum bleed hole 16 on the hollow body 11 of the device to seal the vacuum bleed hole 16, the user ...

second embodiment

[0029] the inserting and handling device 19 as shown in FIG. 3 includes a main body 20. A suction cup 12 is located at a first end of the main body 20 and has an opening 14 that leads to and communicates with an axial channel 21 which extends from a first end of the main body 20 to a second end of the main body 20. The suction cup 12 is shown fitted onto one end of the main body 20. According to this embodiment of the inserting and handling device 19 of the present invention, the hollow main body 20 has a bulb 22. The bulb 22 is flexible and can be formed from any known flexible material which is substantially airtight.

[0030] The bulb 22 allows a user to create a vacuum at the suction cup 12 so as to permit the suction cup 12 to grasp an object such as a contact lens by squeezing the bulb 22 until air is discharged from the opening of the suction cup 12 and then applying a lesser force on the bulb 22 such that a vaccum is formed in the axial channel 21 and at the opening 14 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com