Re-closable Long Term Storage / Preservation Bag (RCLTSP bag); for the prevention of corrosion on military and / or commercial weaponry

a long-term storage and preservation bag technology, applied in the direction of flexible container closure, sustainable manufacturing/processing, arms wearables, etc., can solve the problems of untrained personnel being used to carry out weapon preservation, and achieve the effect of effective corrosion prevention storage and/or shipping enclosure, high degree of puncture and tear resistance, and easy and rapid packing of weapons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

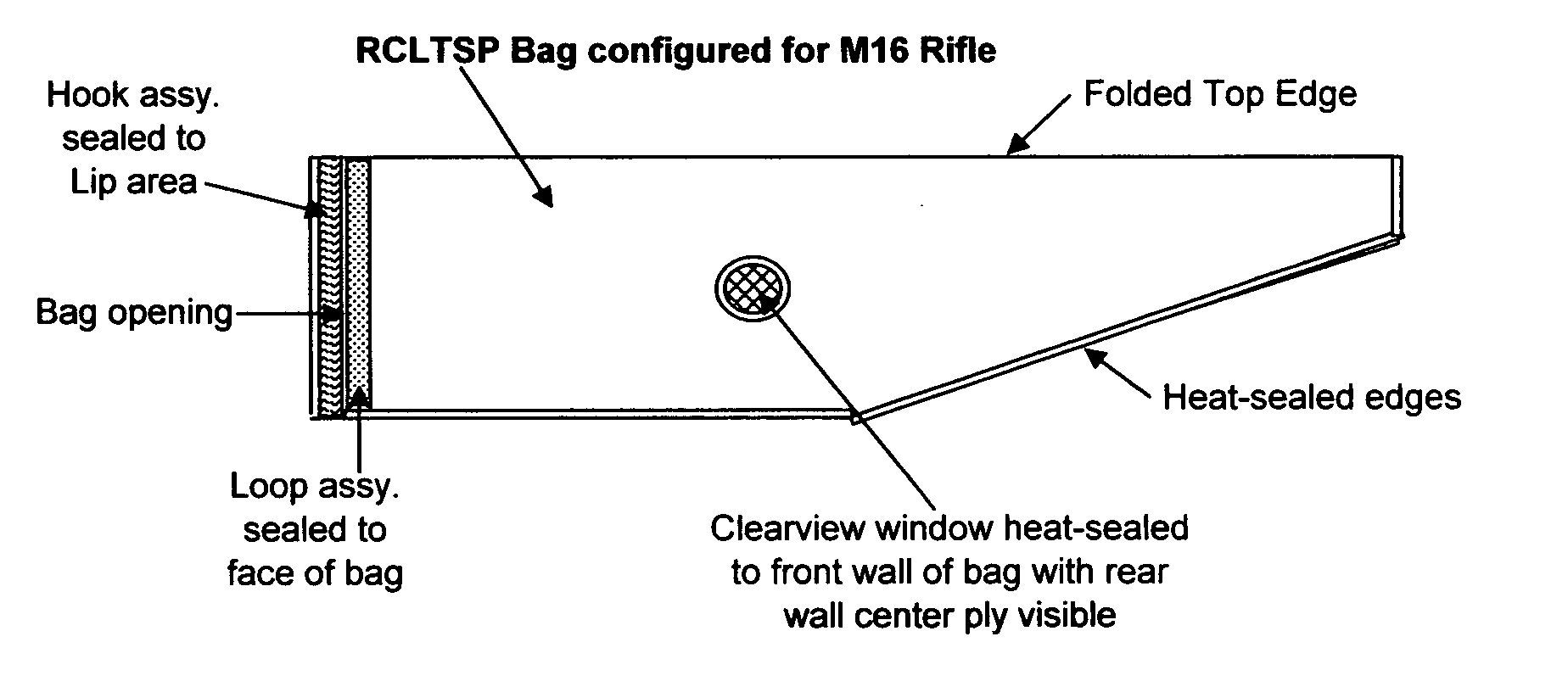

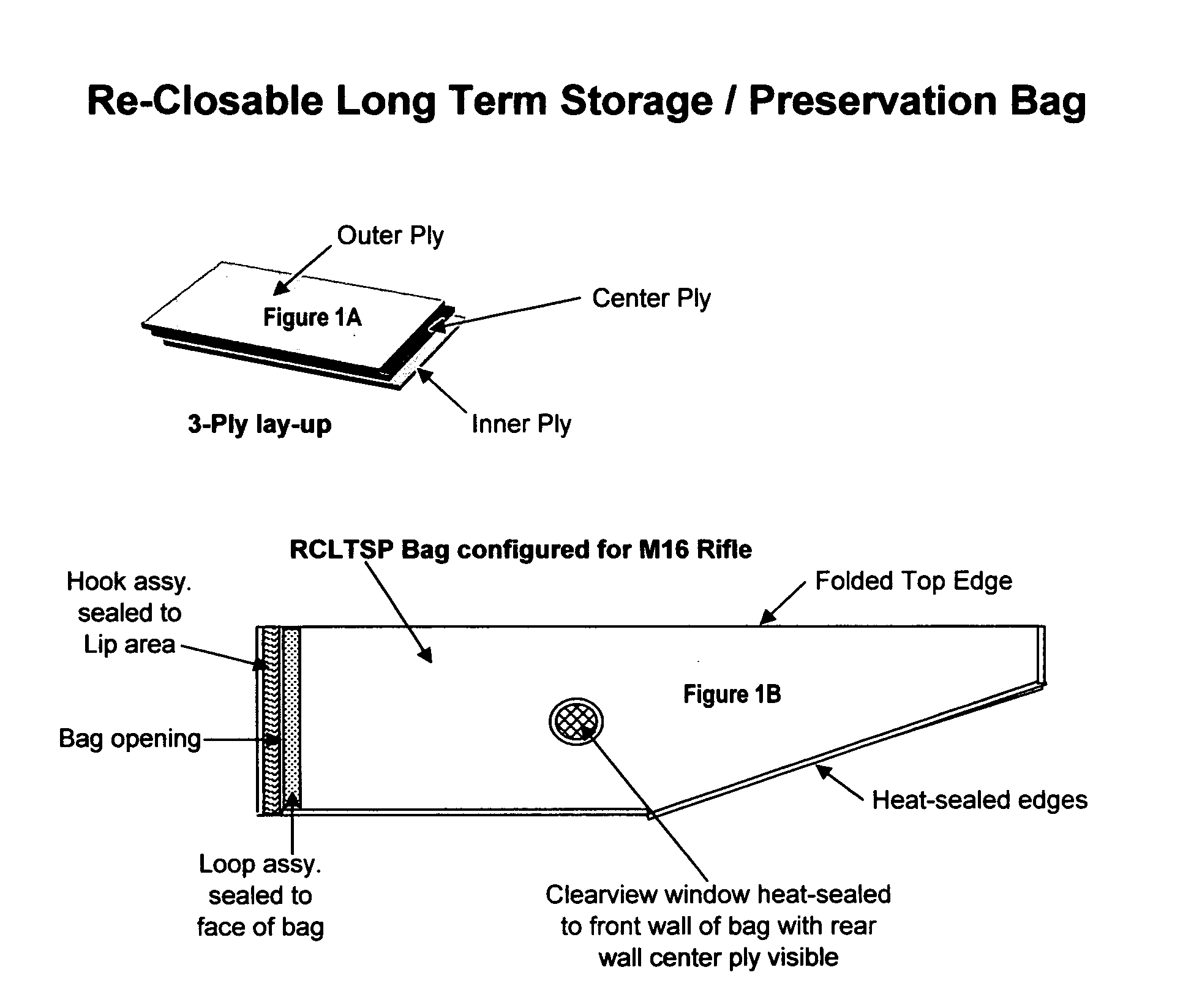

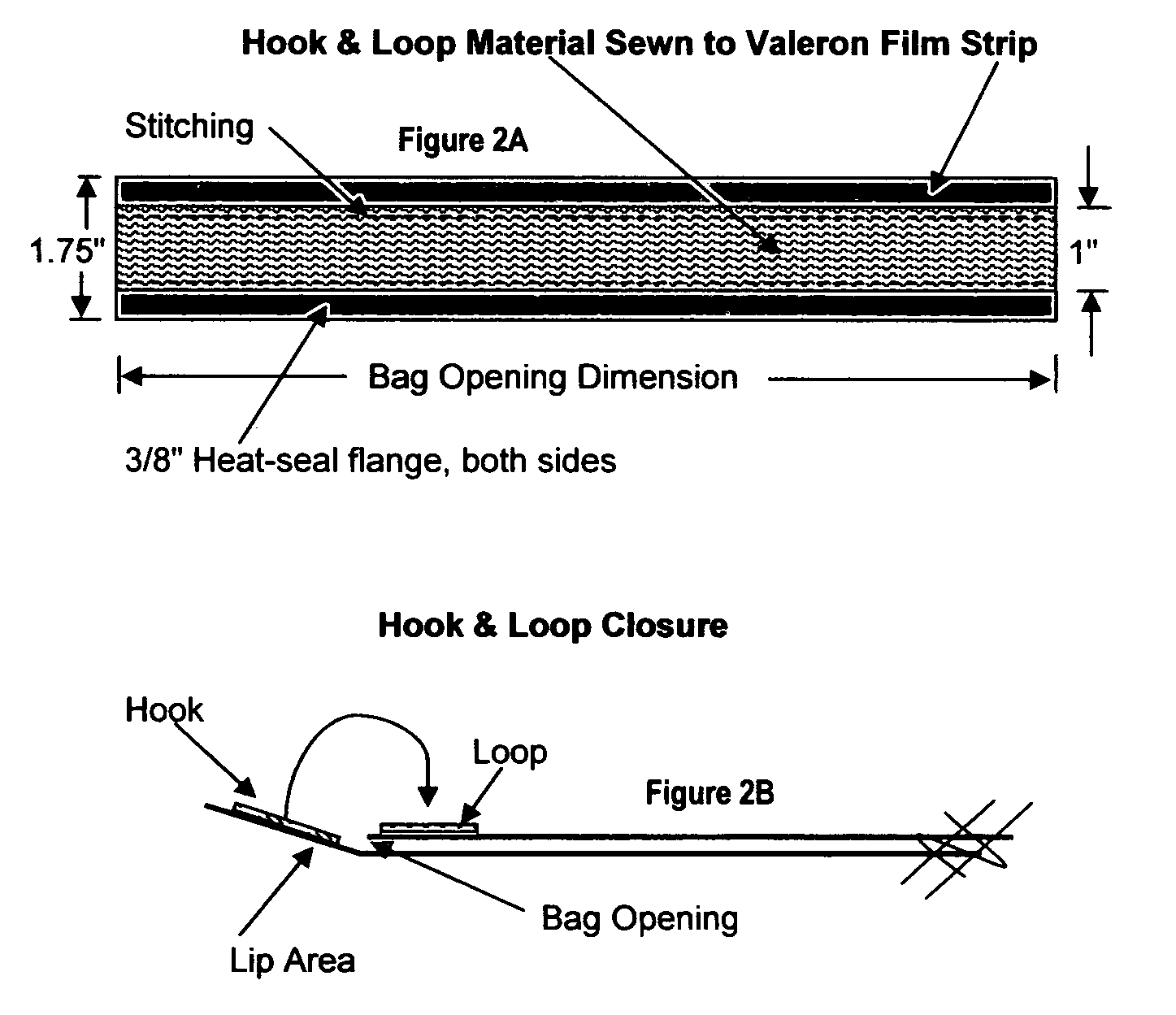

[0015] This invention is a pre-made, re-closable, barrier providing, anti-corrosion protective bag which may, or may not, have a clear viewing port(s) or window(s) installed into the bag wall(s) (see FIG. 1B). The bag shall be of a 3-ply construction utilizing three separate materials that each individually provides certain performance aspects which collectively produce an optimally protective package for whatever metal bearing asset the bag is configured for (see FIG. 1A). Both the outer and inner plies of material must be heat-sealable to one another while the center ply may, or may not be.

[0016] The outer ply is to be a flexible packaging material that provides barrier properties that are equal to or greater than those specified in MIL-PRF-131 J. Typically a film / foil / poly lamination would be utilized, however; any heat-sealable flexible material that exhibits barrier capacity as noted above may be utilized as the outer ply. Examples of possible substitute materials for the tri-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com