Combined piston fluid motor and pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

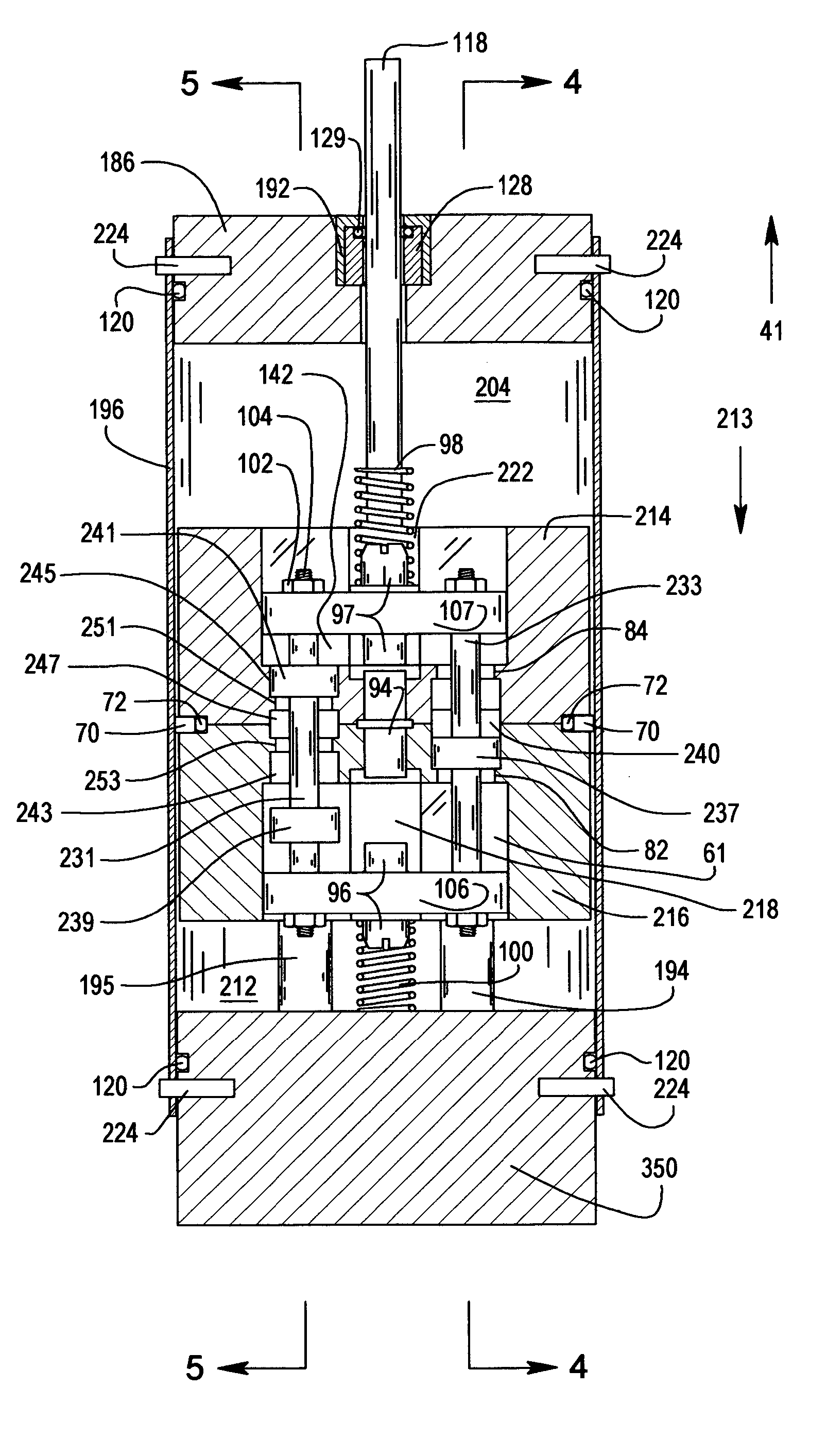

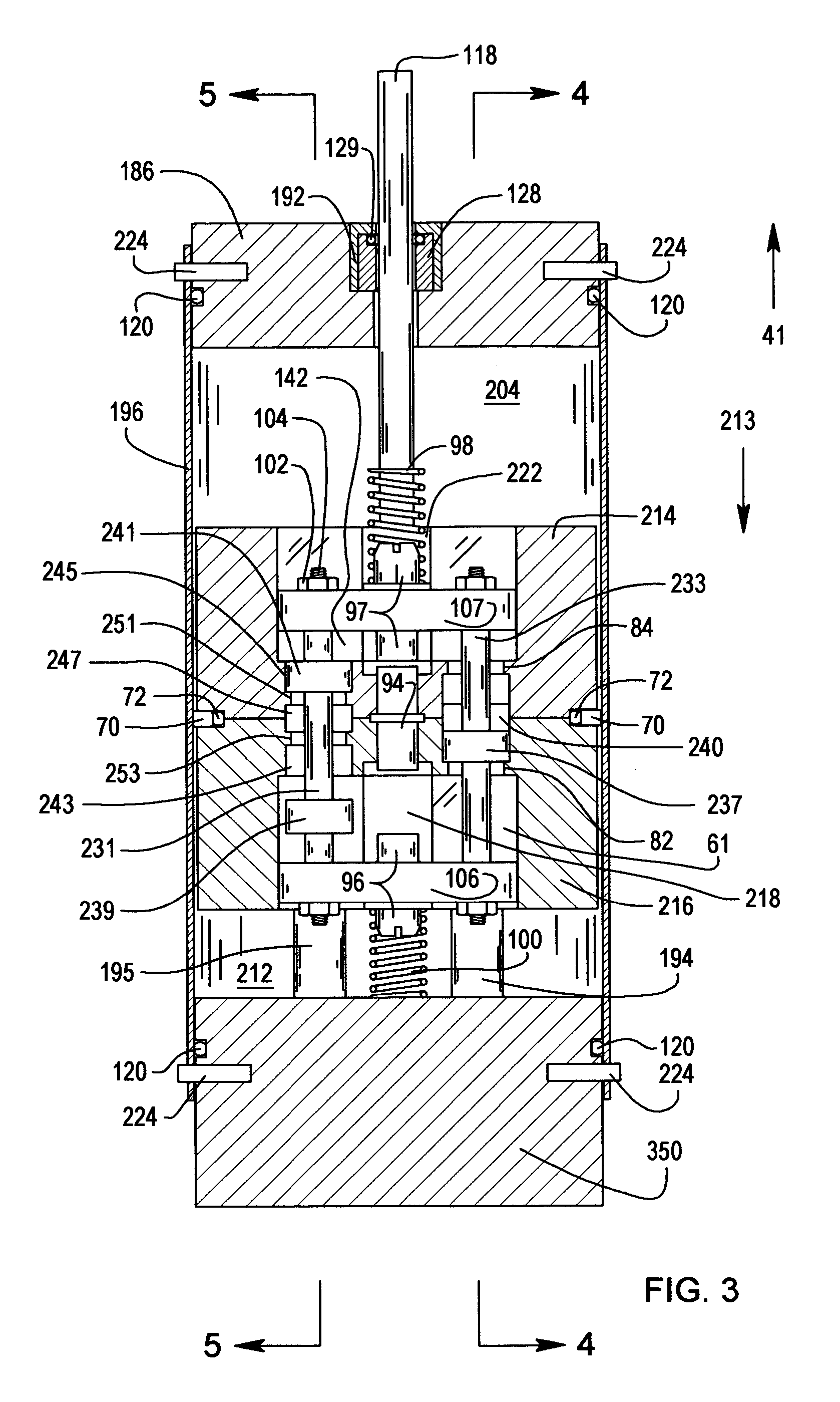

[0061] Reference will now be made in detail to exemplary embodiments of the invention, an example of which is illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

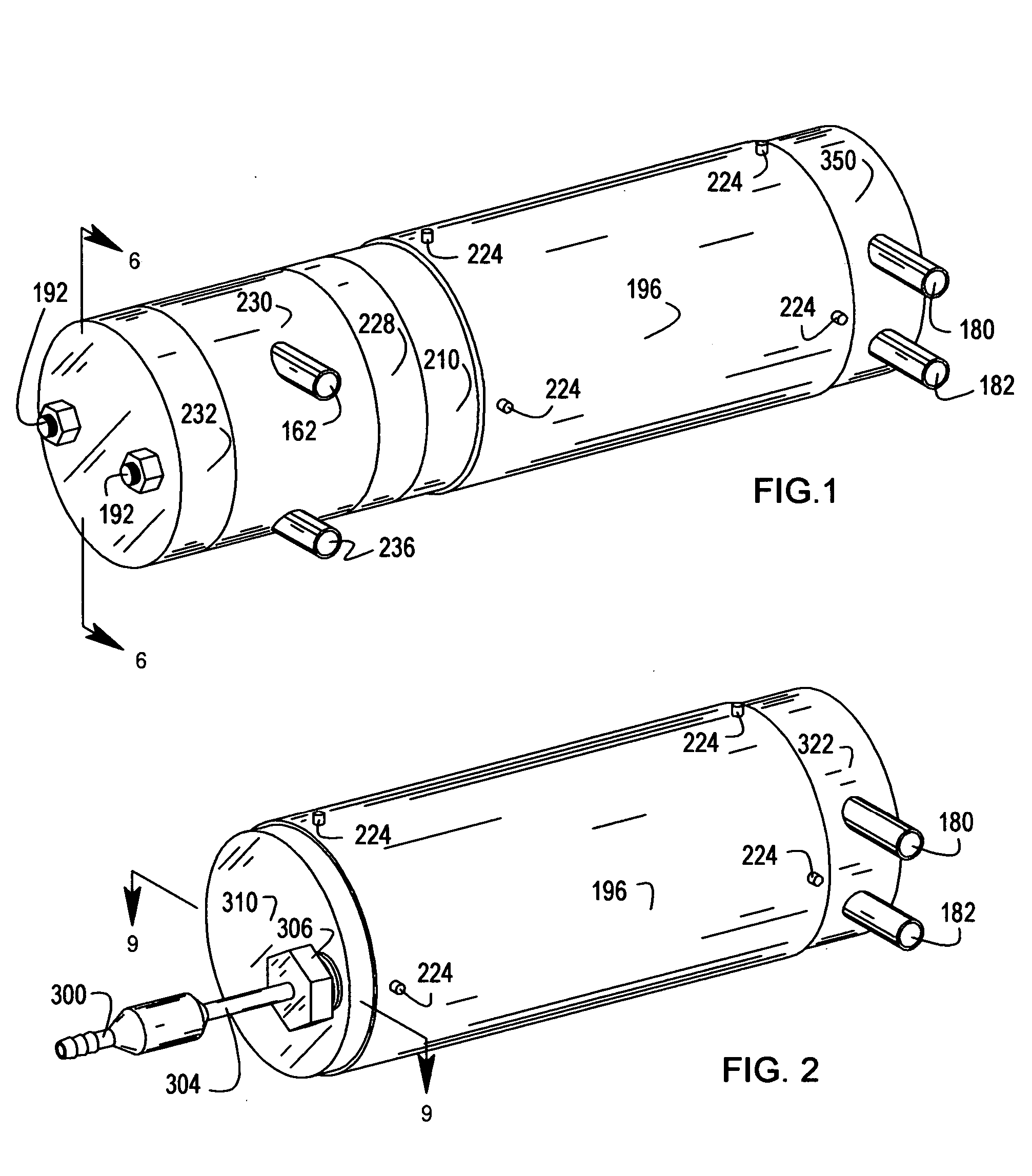

[0062]FIG. 1 shows a trimetric, general arrangement of an exemplary end port motor combined with an exemplary close coupled, shaft connected, fixed displacement pump in one exemplary embodiment of the present invention. A exemplary fluid motor housing is comprised of end cap 210, casing 196 and end cap 350. End cap 350 contains inlet port 180 and outlet port 182. End cap 350 and end cap 210 may be connected to casing 196 using any attachment system, including, for example, dowels 224.

[0063] An exemplary fluid pump is comprised of housing segments 228, 230 and 232. Segment 230 contains pump inlet port 162 and pump outlet port 236. Segments 232, 230, 228, and end cap 210 may be held together in compression by fastener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com