Abrasion-resistant sleeve for wiring and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

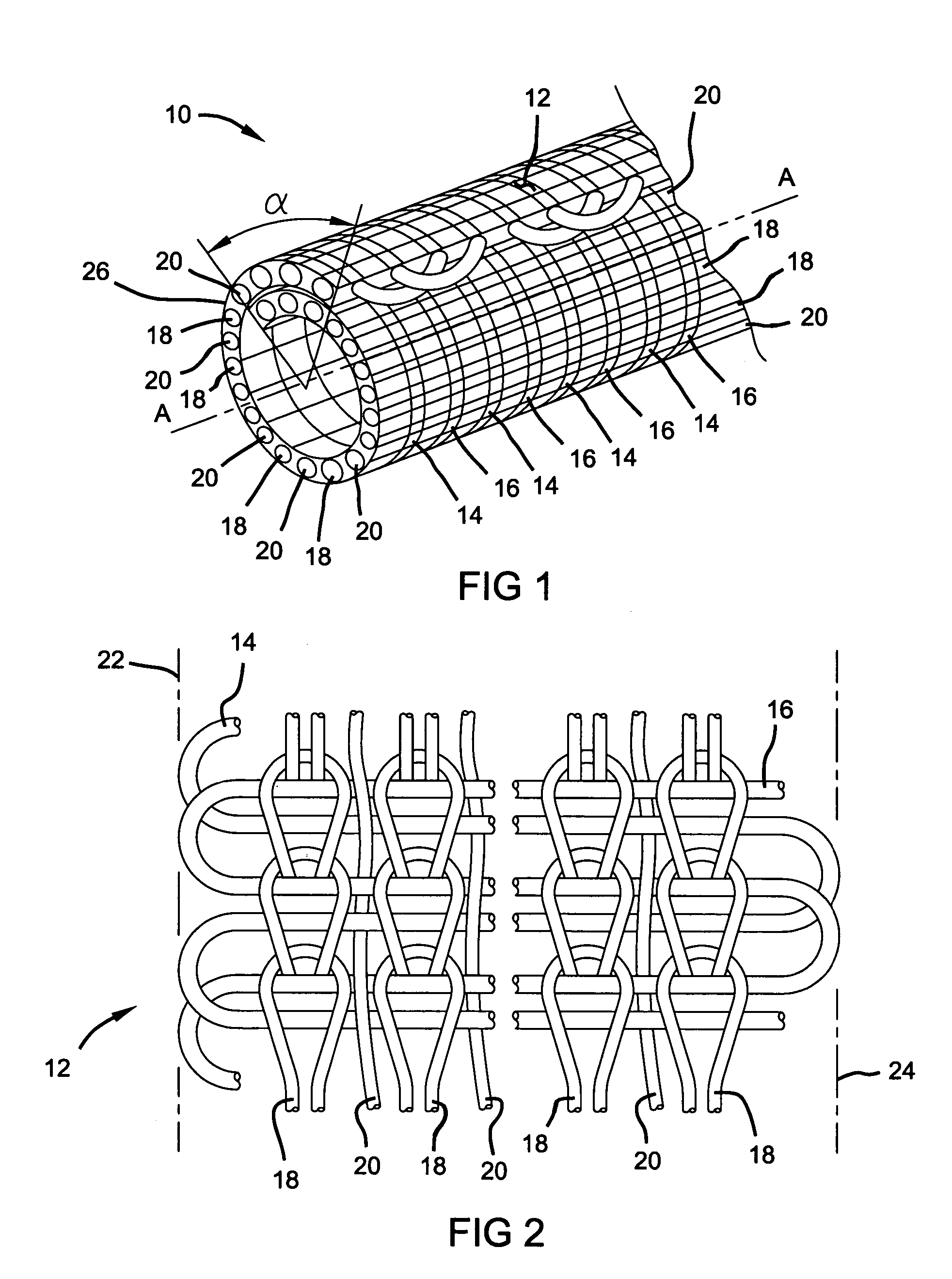

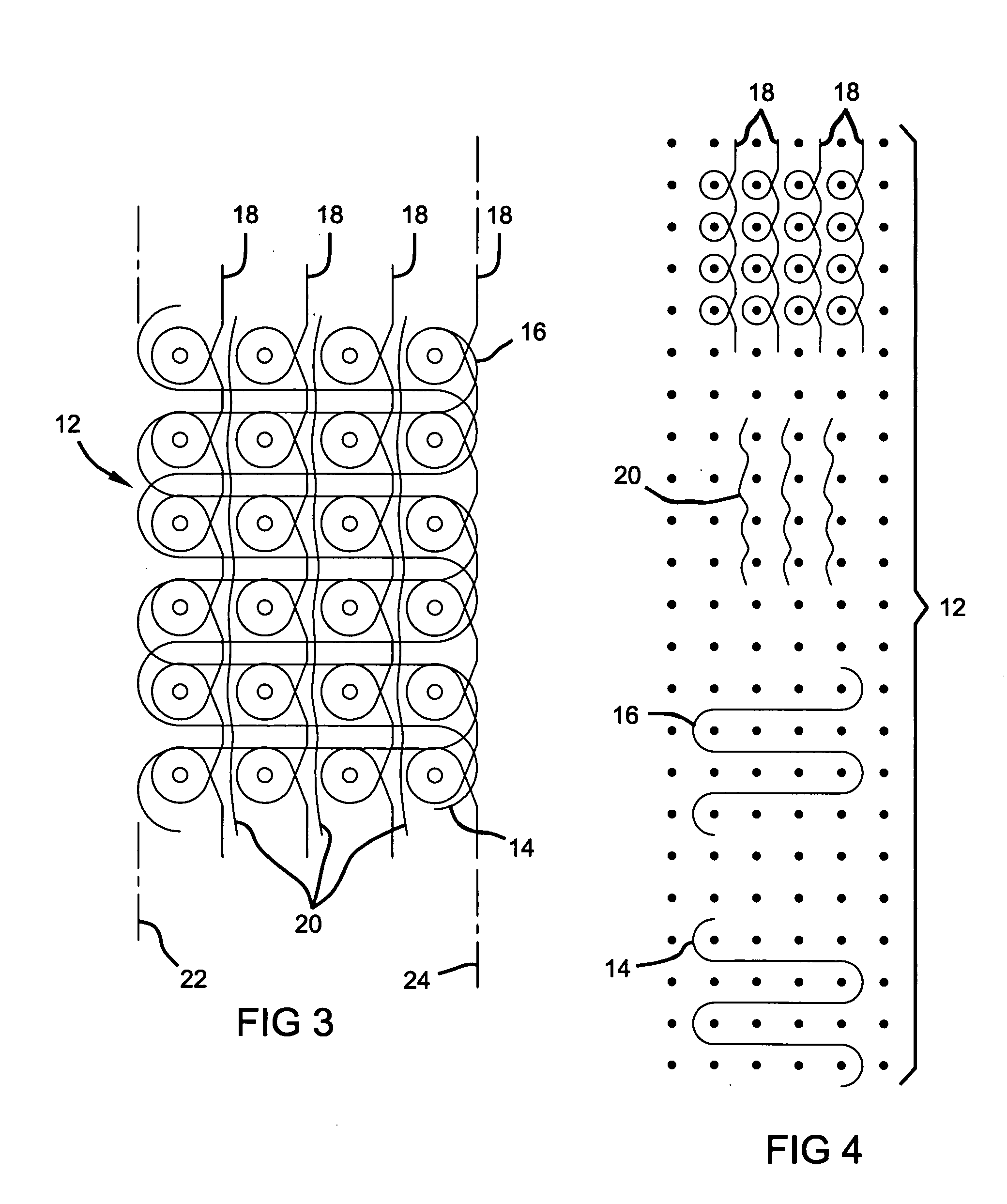

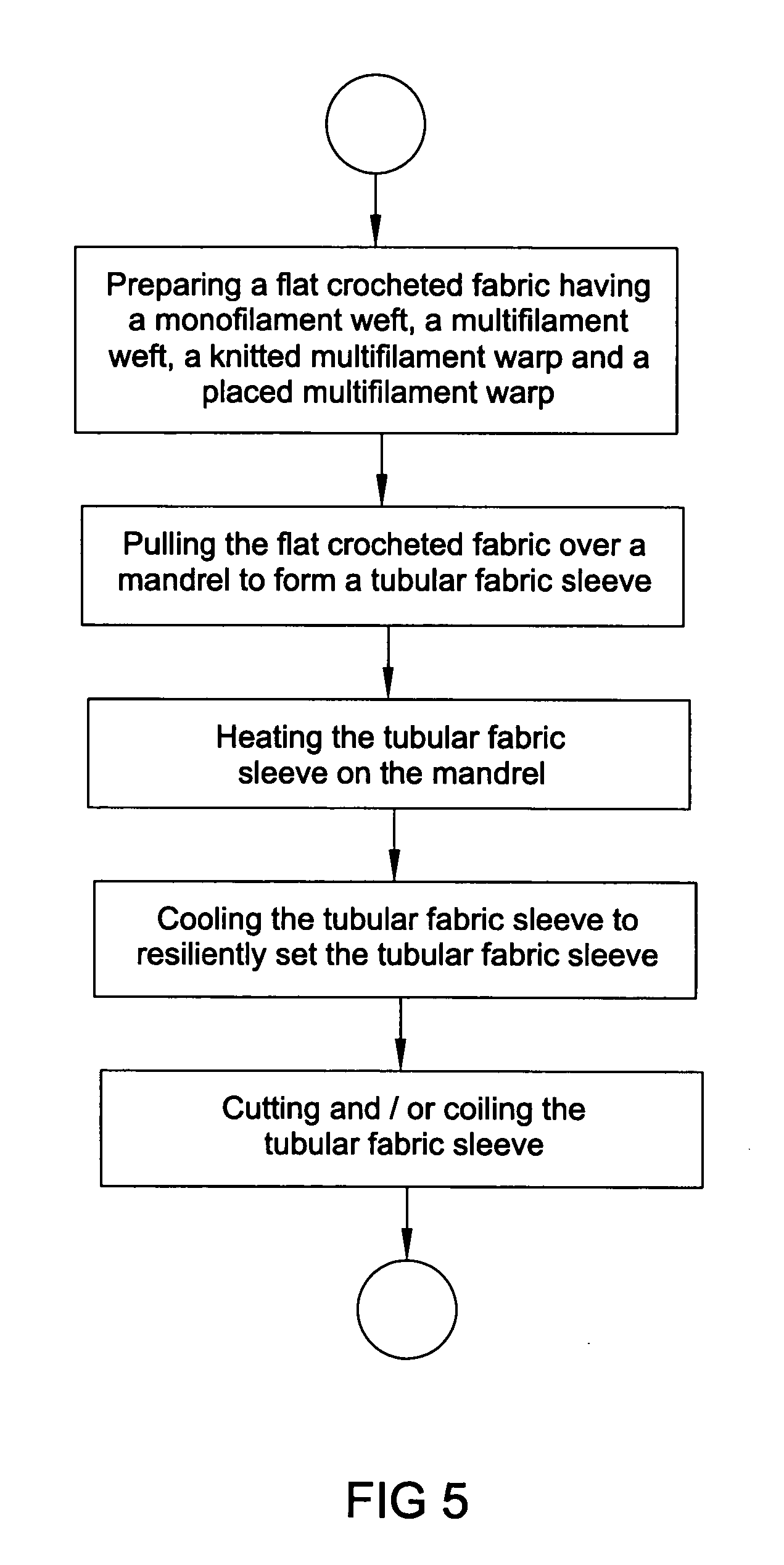

[0014] With reference to FIGS. 1-4, the present invention is directed to a generally flat crocheted fabric cloth 12 formed into a resilient sleeve which maintains its tubular shape. The fabric cloth 12 includes a monofilament yarn 14 forming a first weft and a textured multifilament yarn 16 forming a second weft in the fabric cloth 12. Fabric cloth 12 further includes a set of crocheted warps in the form of textured multifilament yarns forming a chain stitch lap 18 in the fabric cloth 12. In a preferred embodiment, the fabric cloth 12 further includes a set of placed warps including a plurality of multifilament yarns forming a lay-in stitch lap 20 in fabric cloth 12. The lay-in stitch lap 20 is utilized to fill the spacing on the face of the fabric cloth 12 in between the chain stitch lap 18 to provide a smoother surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com