Suction head for vacuum cleaner

a vacuum cleaner and suction head technology, applied in the direction of vacuum cleaners, cleaning equipment, domestic applications, etc., can solve the problems of shortening the life inconvenient cleaning of the suction head b>2/b>, and failure of the vacuum cleaner, so as to facilitate the cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

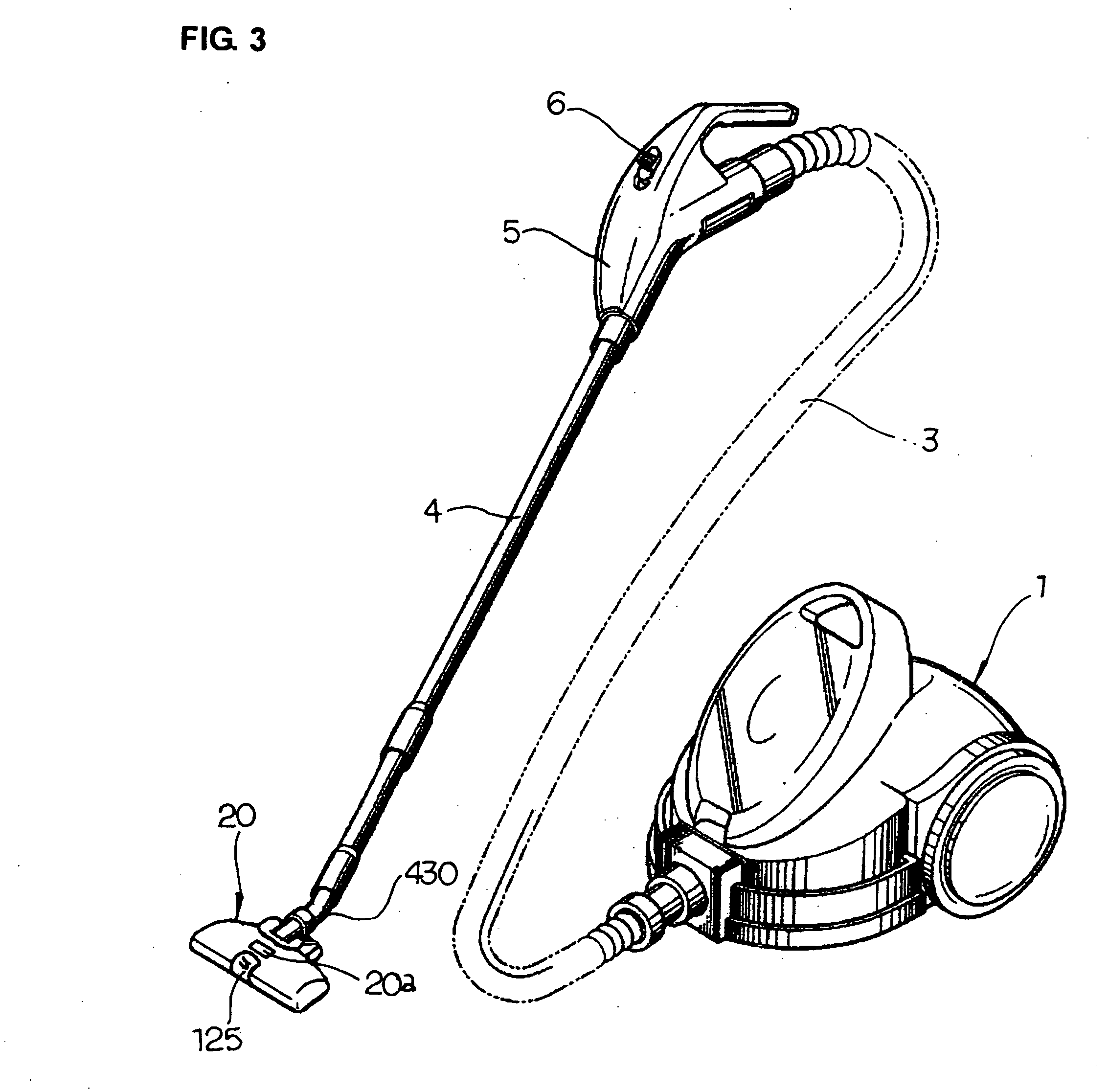

[0029]FIG. 3 is a perspective view showing a vacuum cleaner equipped with a suction head according to the present invention, in which the same reference numeral as shown in FIG. 1 designates the same component and it is not described in detail here.

[0030] As shown in FIG. 3, the suction head according to the present invention includes a main body 20, and the main body 20 includes upper and lower cases 21 and 22 combined in contact with each other. A connection member 430 communicated with the main body 1 of the vacuum cleaner is mounted to one side of the suction head, and a suction hole 121 is formed in the lower case 22 adjacent to the connection member 430.

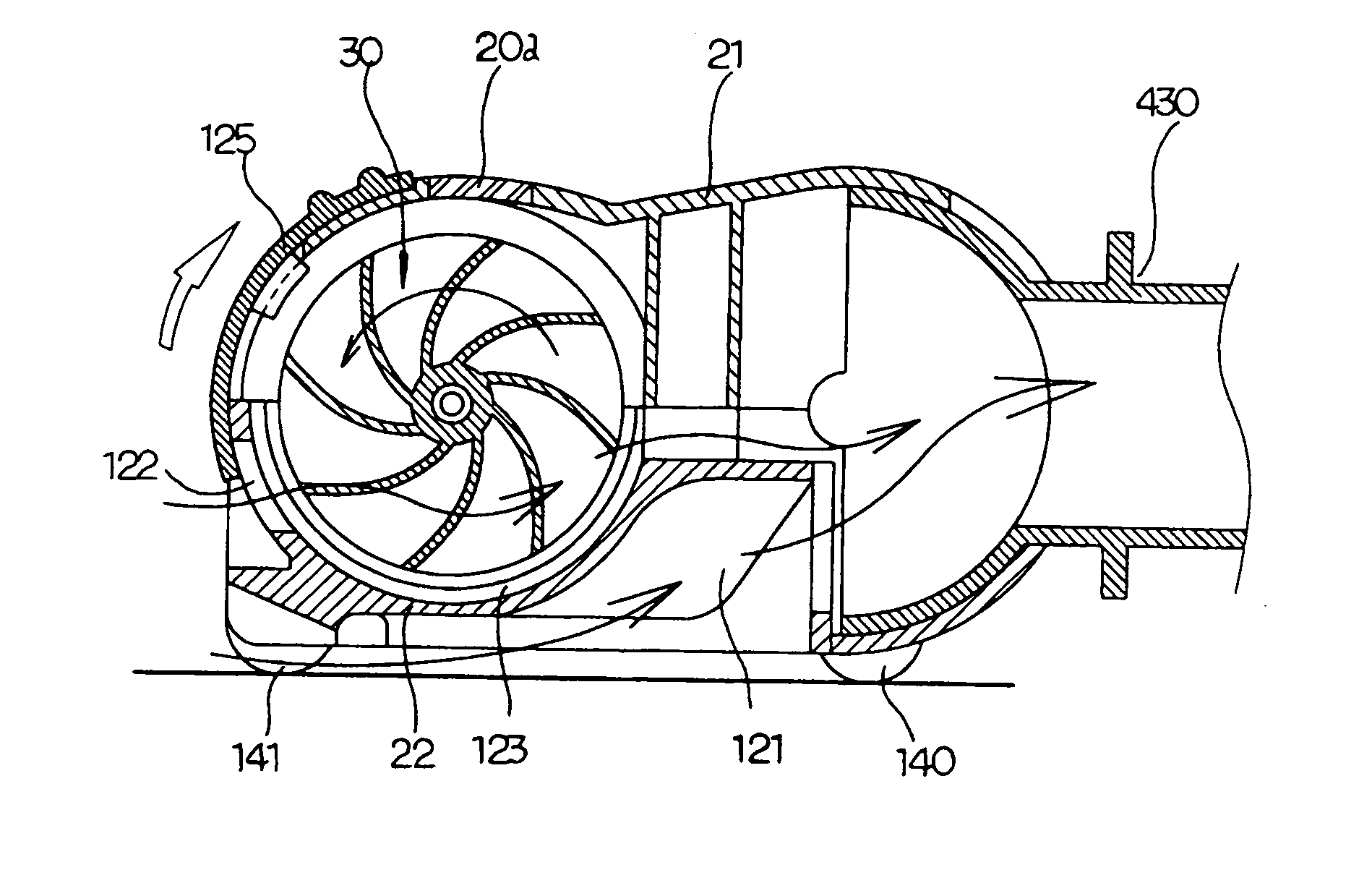

[0031] In addition, an air introduction hole 122 is formed in front of the suction hole 121 so as to selectively operate a turbine 30 and control a rotating speed of the turbine 30, and a turbine container 123 and a plurality of sliding holes 124 are formed between the air introduction hole 122 and the suction hole 121. As we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com