Method of fabricating custom-fitted footbed

a technology of custom-fitting footbeds and footbeds, which is applied in the field of footbed fabrication, can solve the problems of relative stiffness and unyelding, unsuitability of certain footwear insoles fabricated by this process, and burns to wearers during their fabrication, so as to avoid injury or burns to wearers, simple and rapid manner, and minimal effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

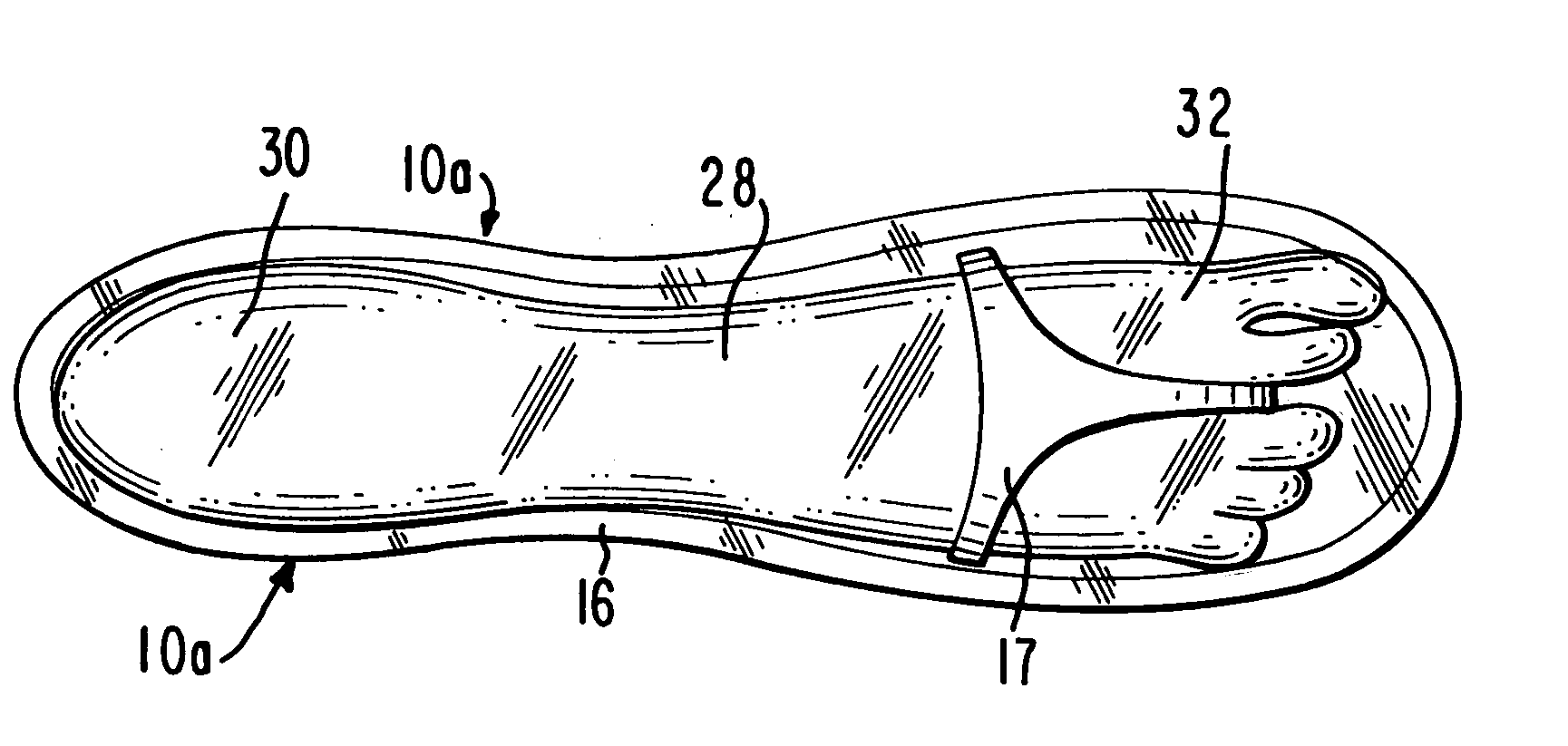

[0021] Referring to the drawings, there is shown in FIG. 1 a moldable footbed generally designated 10, which as therein shown, is generally in the shape of a human foot having a toe end 12, a heel end 14 and a central arch portion 15. A thong or toe strap 17 is secured to the forward end of the footbed 10. The thong or toe strap 17 may me made either of hemp, a standard cloth-like fabric, a biological nutrient that can be returned to the biological cycle, or a biodegradable cloth-like fabric such as that sold under the trade name Polyactide by Cargill Dow of Minnetonka, Minn.

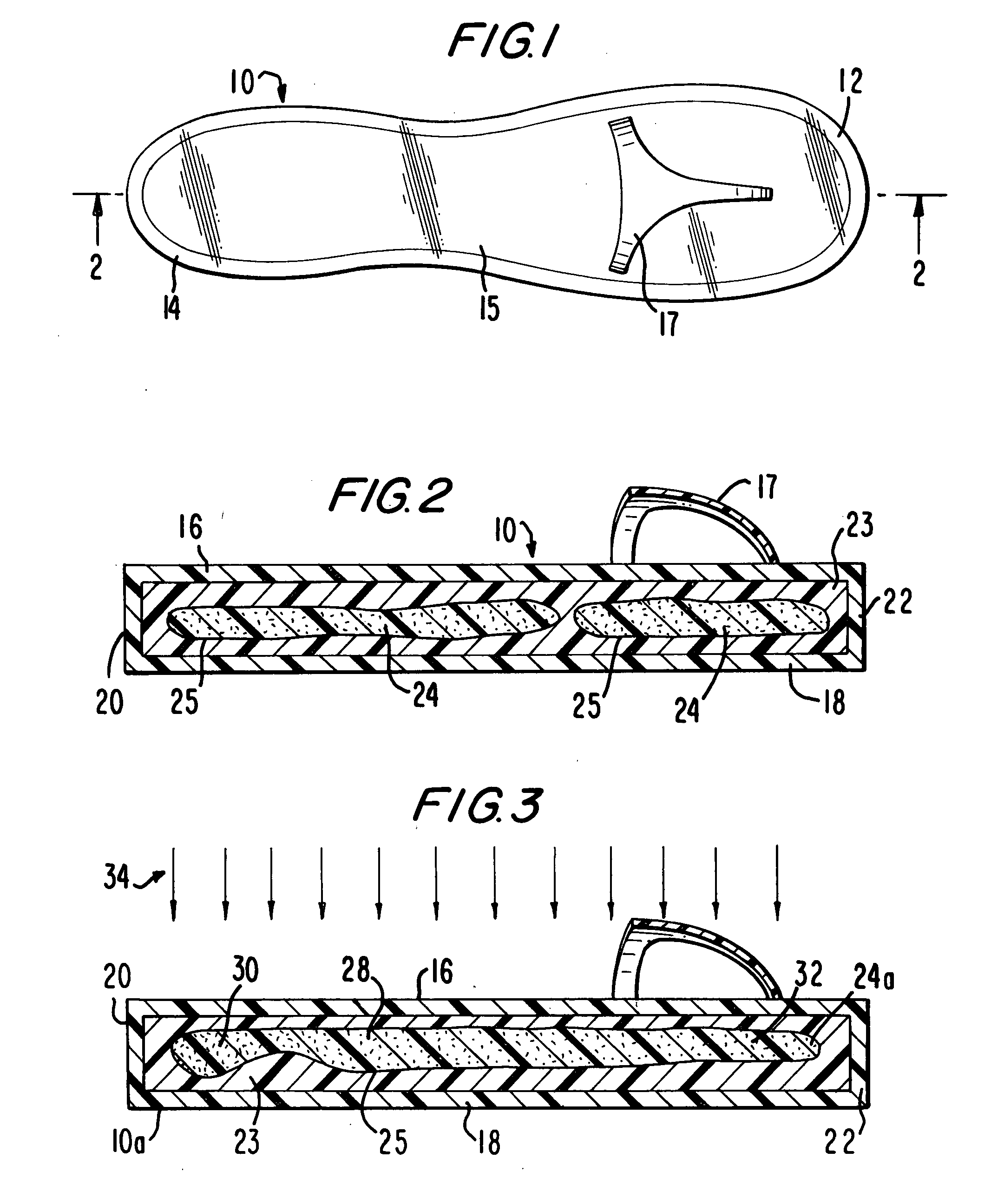

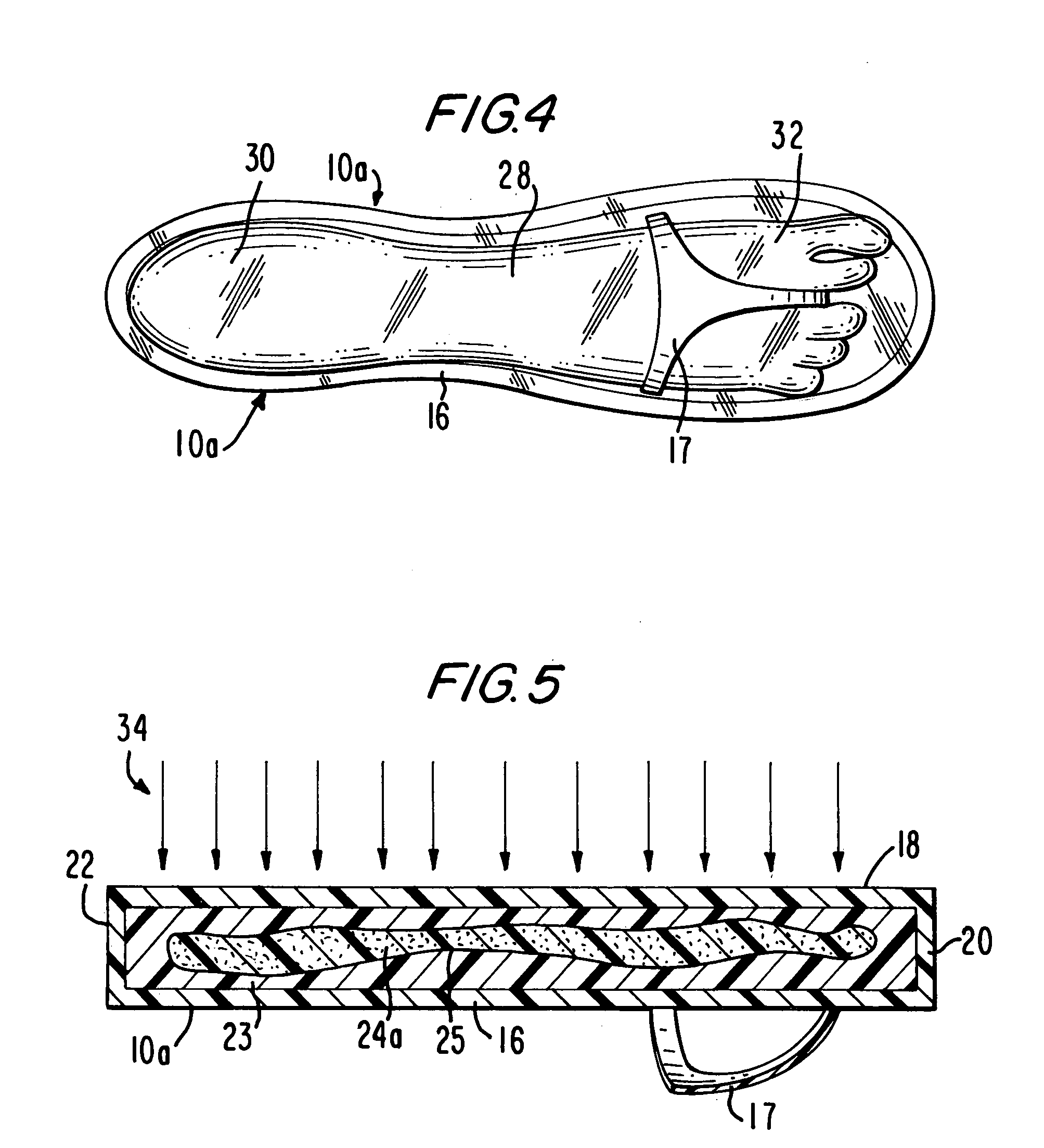

[0022] As shown in FIG. 2, the unformed footbed 10, prior to being molded to conform to the wearer's foot in the manner described below, includes an upper contact layer 16, a lower or bottom layer 18 and front, rear and side walls 20 and 22. The upper layer 16 is preferably relatively thin, typically between 1 / 16 and ½ inch, and is made of a flexible or moldable material made up of a foam rubber material, a rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com