Gun trigger actuator

a technology of trigger actuator and trigger, which is applied in the direction of firing/trigger mechanism, weapons, ammunition loading, etc., can solve the problems of affecting the firing accuracy of the trigger, the inability to accurately determine the trigger position, so as to reduce the possibility of injury to the shooter, reduce the possibility of overtravel and premature hammer tripping, and minimize unnecessary forward movement of the trigger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

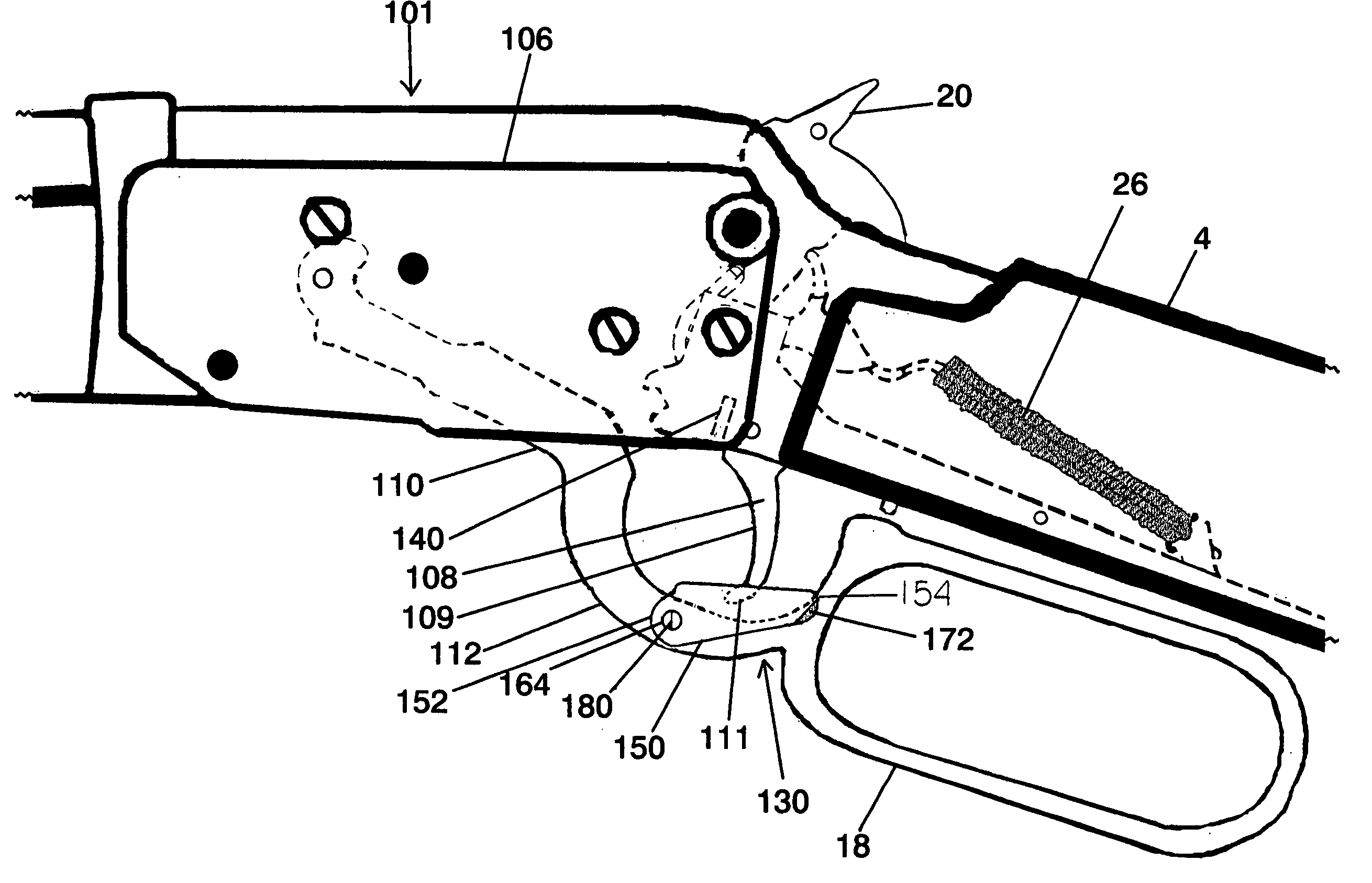

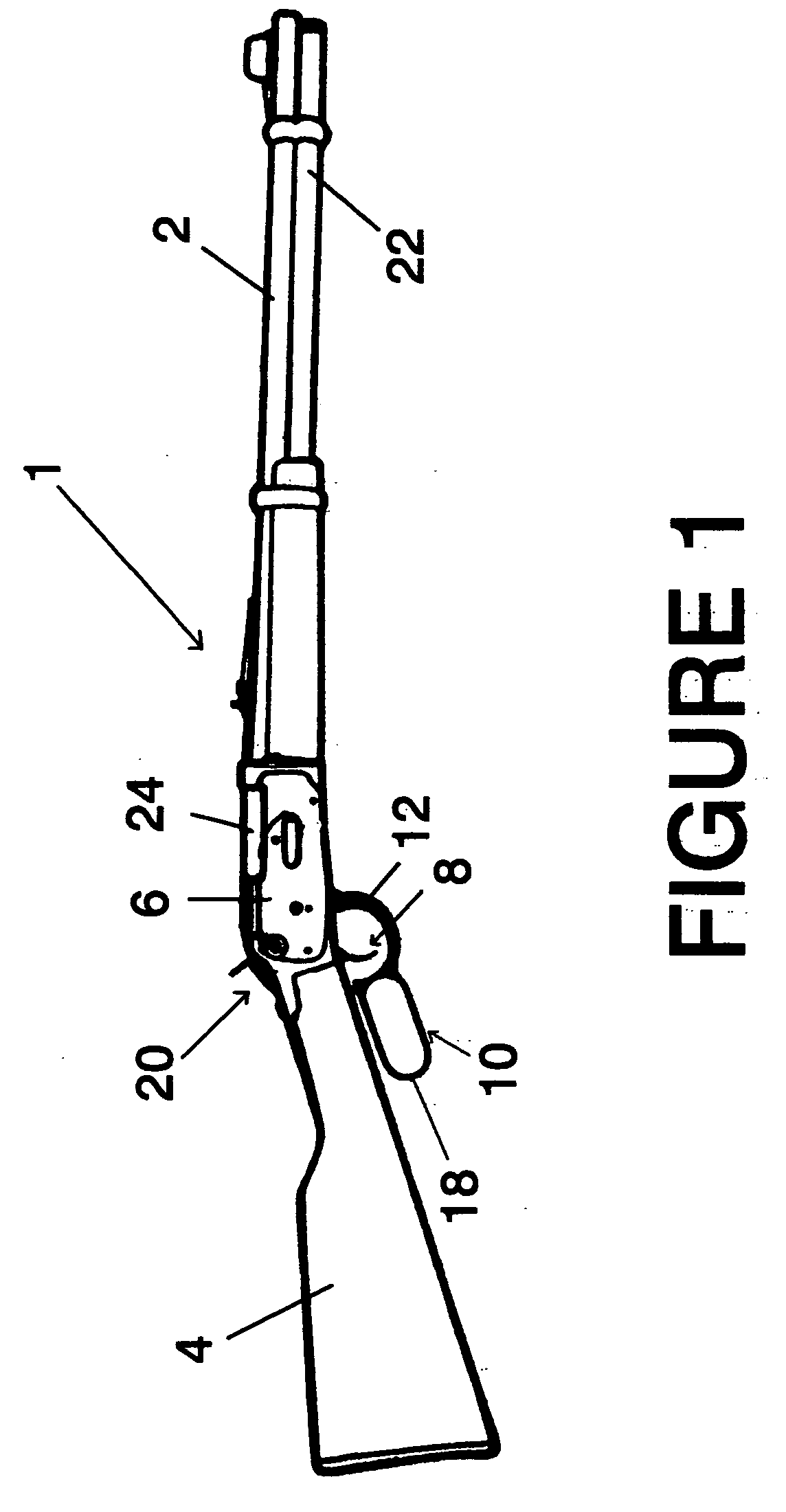

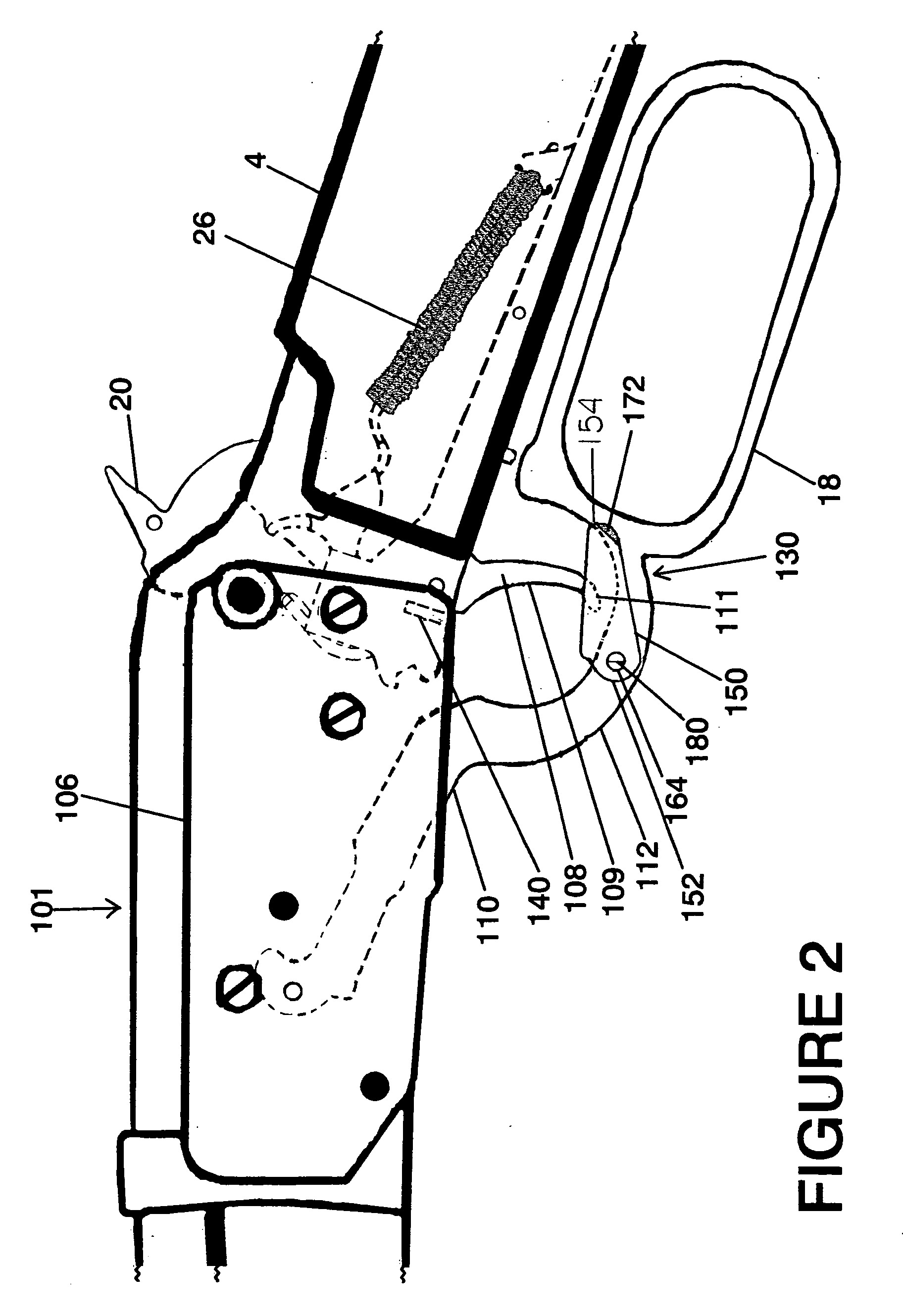

[0036] With reference to the Figures, FIG. 1 shows a prior art Winchester lever action rifle 1, having a barrel 2, a stock 4, a receiver 6, a trigger 8, a lever 10 having a trigger guard 12 towards the lever 10 front end and a finger lever 18 comprising the back portion of the lever 10, a hammer 20, a magazine 22, and an ejection port 24. When a live cartridge is in the chamber, the rifle 1 may be fired by cocking the hammer 20 and manually pulling or exerting rearward pressure on the trigger 8. If the magazine 22 contains one or more cartridges, another cartridge may be chambered after a cartridge is fired by rotating the lever 10 down through a short arc until the lever 10 is fully forward or open. This action of the lever 10 extracts the empty cartridge case from the chamber and ejects the empty cartridge through the ejection port 24, cocks the hammer 20 and chambers a fresh cartridge. Closing the lever 10, which positions the lever 10 close to and generally parallel with the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com