Roller level adjustment device for roller blind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

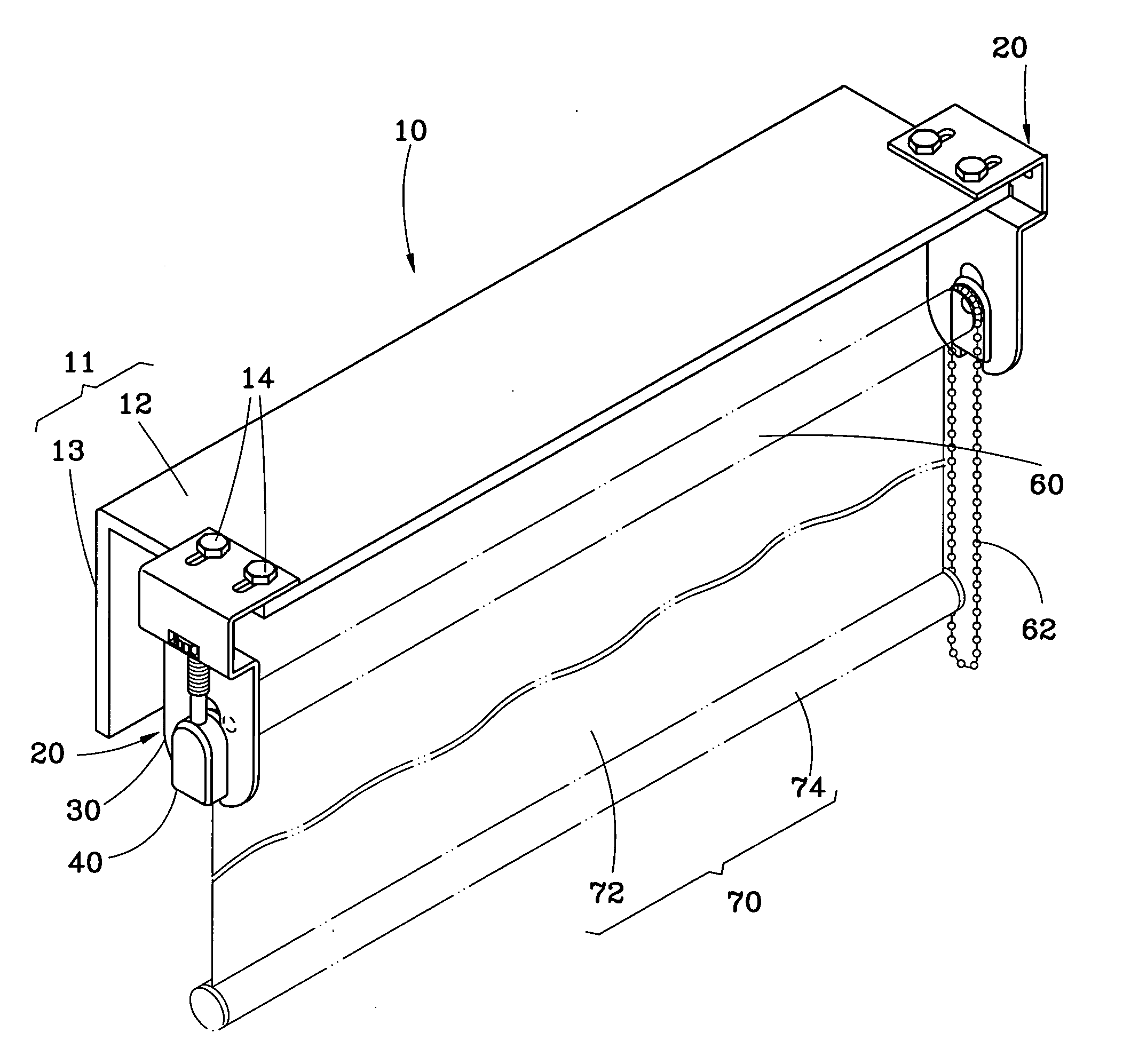

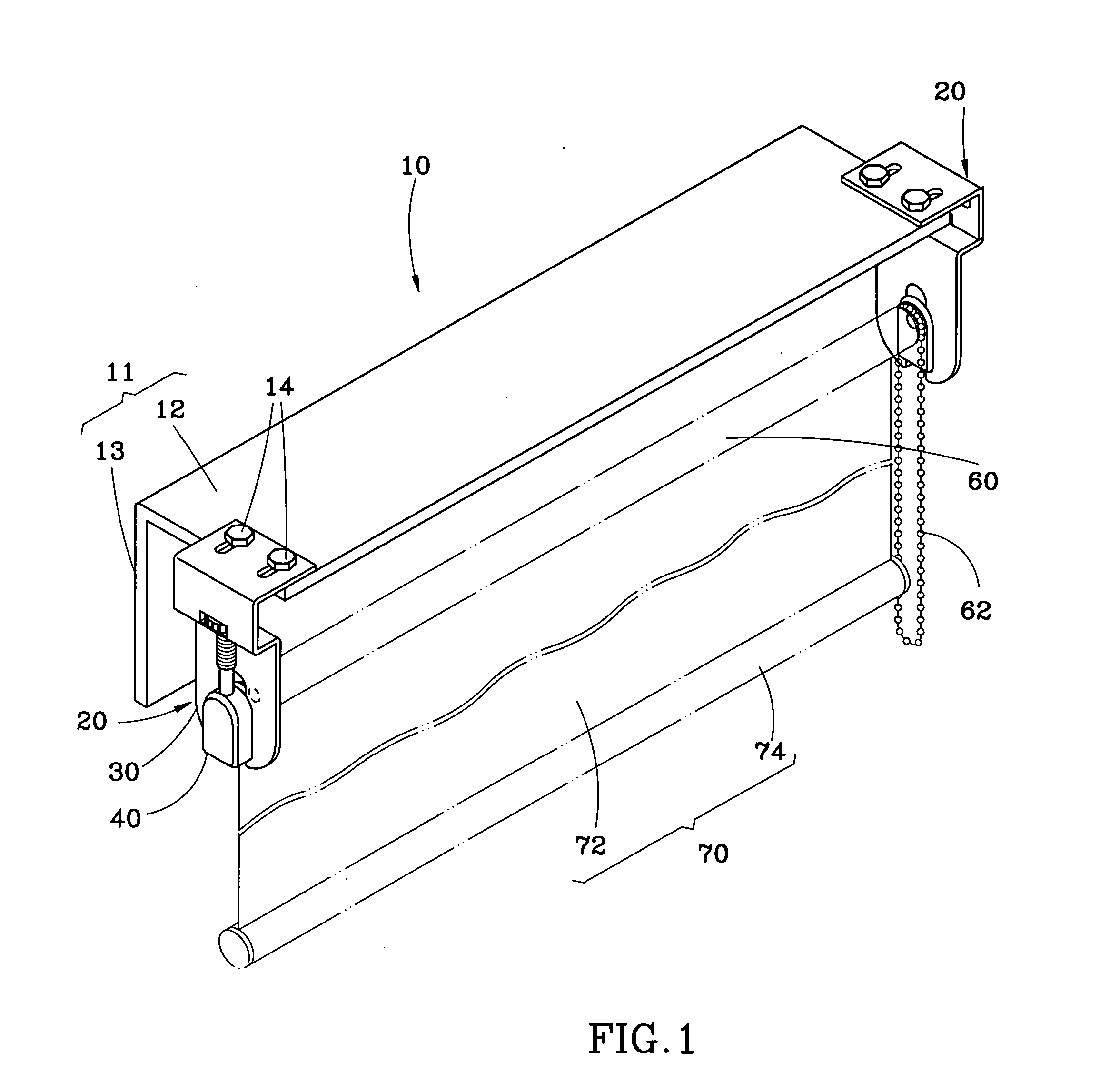

[0014] Referring to FIGS. 1-4, two roller level adjustment devices 20 are shown used in a roller blind 10. The roller blind 10 comprises a bracket 11, a roller 60, and a shade 70. The bracket 11 is shaped like an angle bar, having a top wall 12 transversely (horizontally) provided at the top side of the window, and a side wall 13 perpendicularly downwardly extended from the top wall 12 along the length. The roller 60 is a cylinder transversely (horizontally) pivotally connected between the roller level adjustment devices 20 below the top wall 12 of the bracket 11. An operating cord (chain) 62 is provided at one end of the roller 60 for pulling by the user to rotate the roller 60. The shade 70 comprises a fabric shade body 71 and a weight rod 72. The roller level adjustment devices 20 are provided at the two distal ends of the bracket 11.

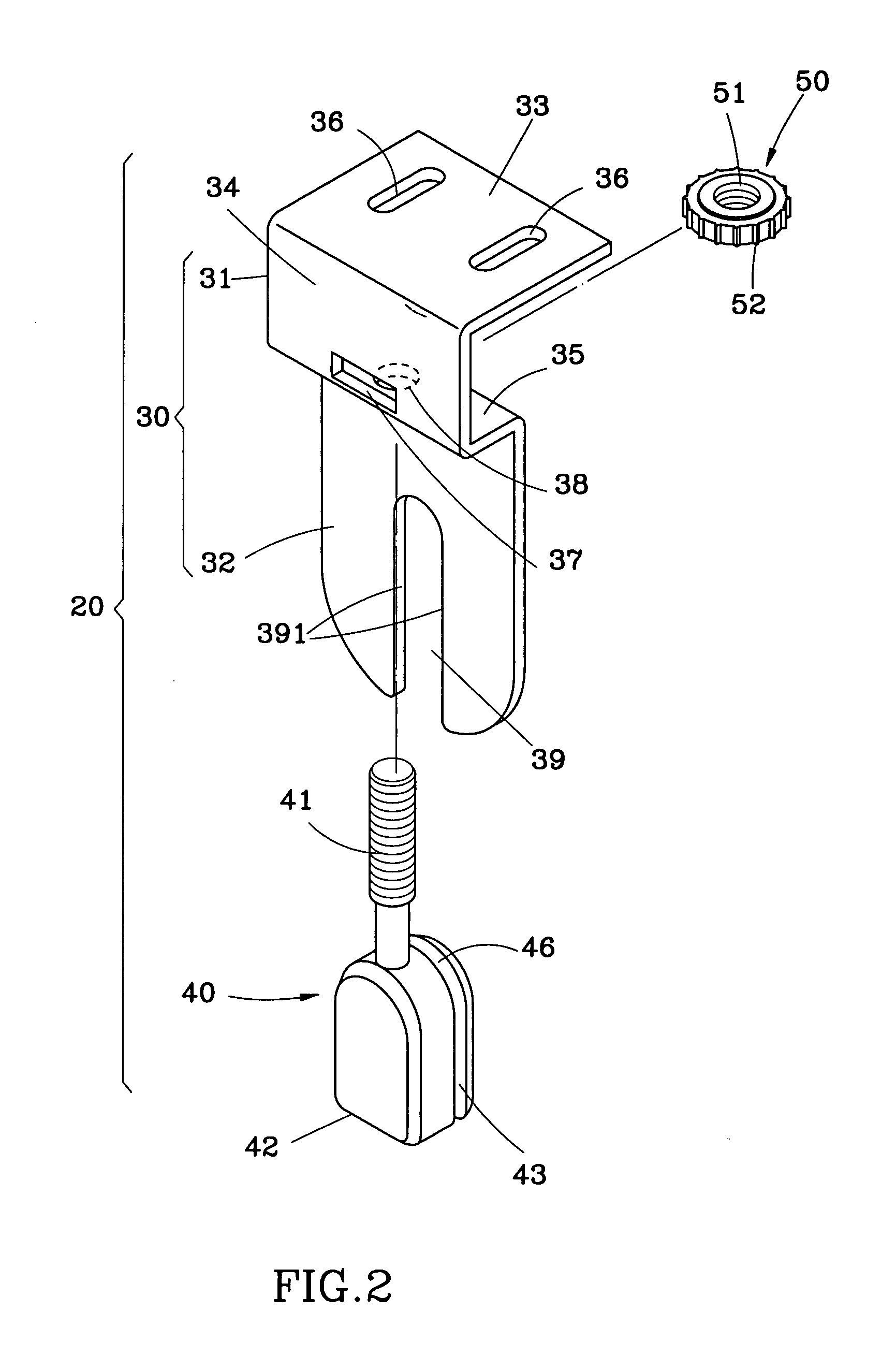

[0015] Each roller level adjustment device 20 comprises a base frame 30, a moveable member 40, and an adjustment member 50. The base frame 30 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com