Indexable cutting inserts and methods for producing the same

a cutting edge and indexing technology, applied in the direction of cutting inserts, tool workpiece connection, manufacturing tools, etc., can solve the problems of limiting the useful operating period of that particular cutting edge, superhard material presented to the workpiece, and inherent weak point in the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Exemplary arrangements and techniques according to the present invention will now be described by reference to the drawing figures.

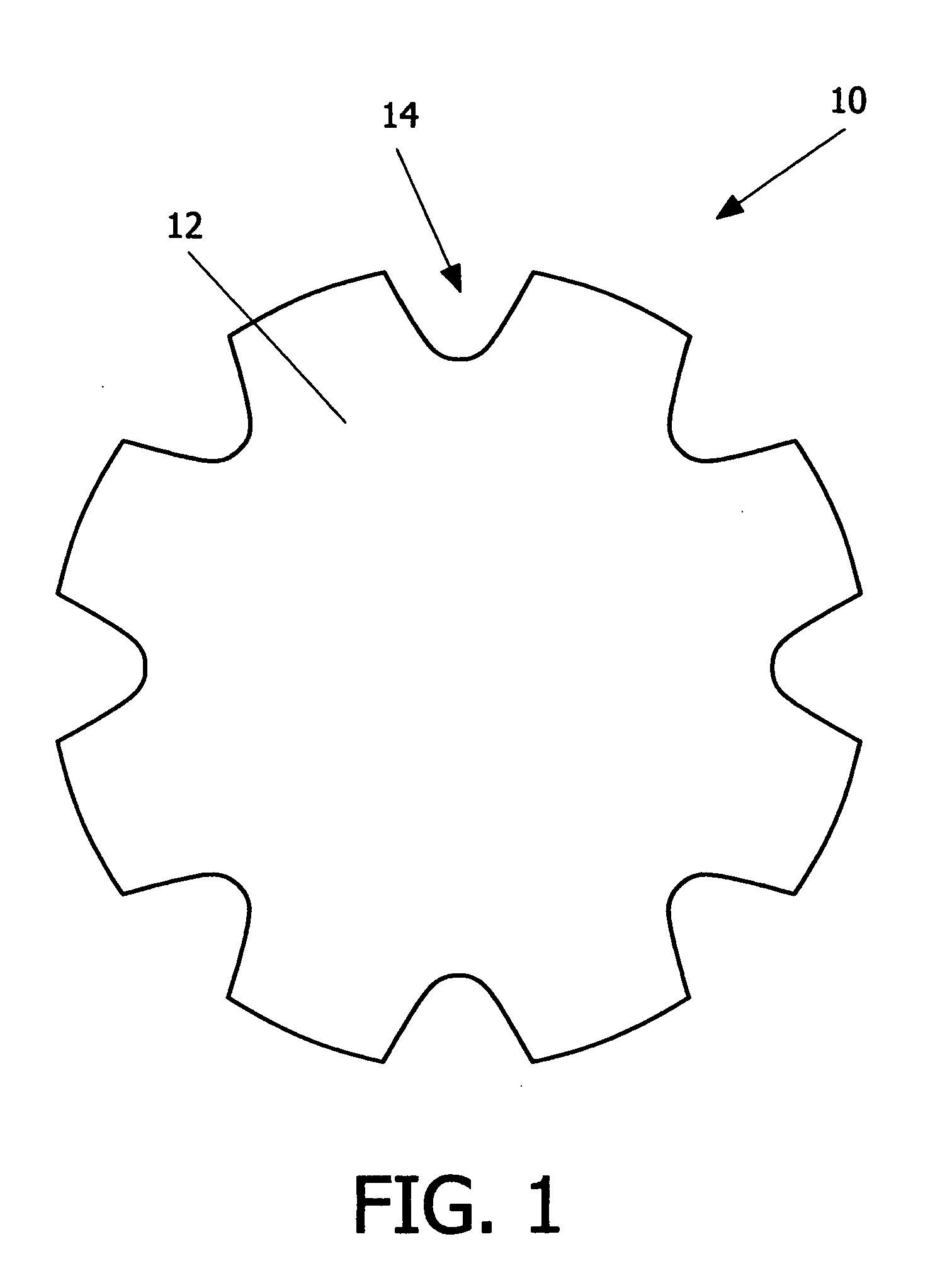

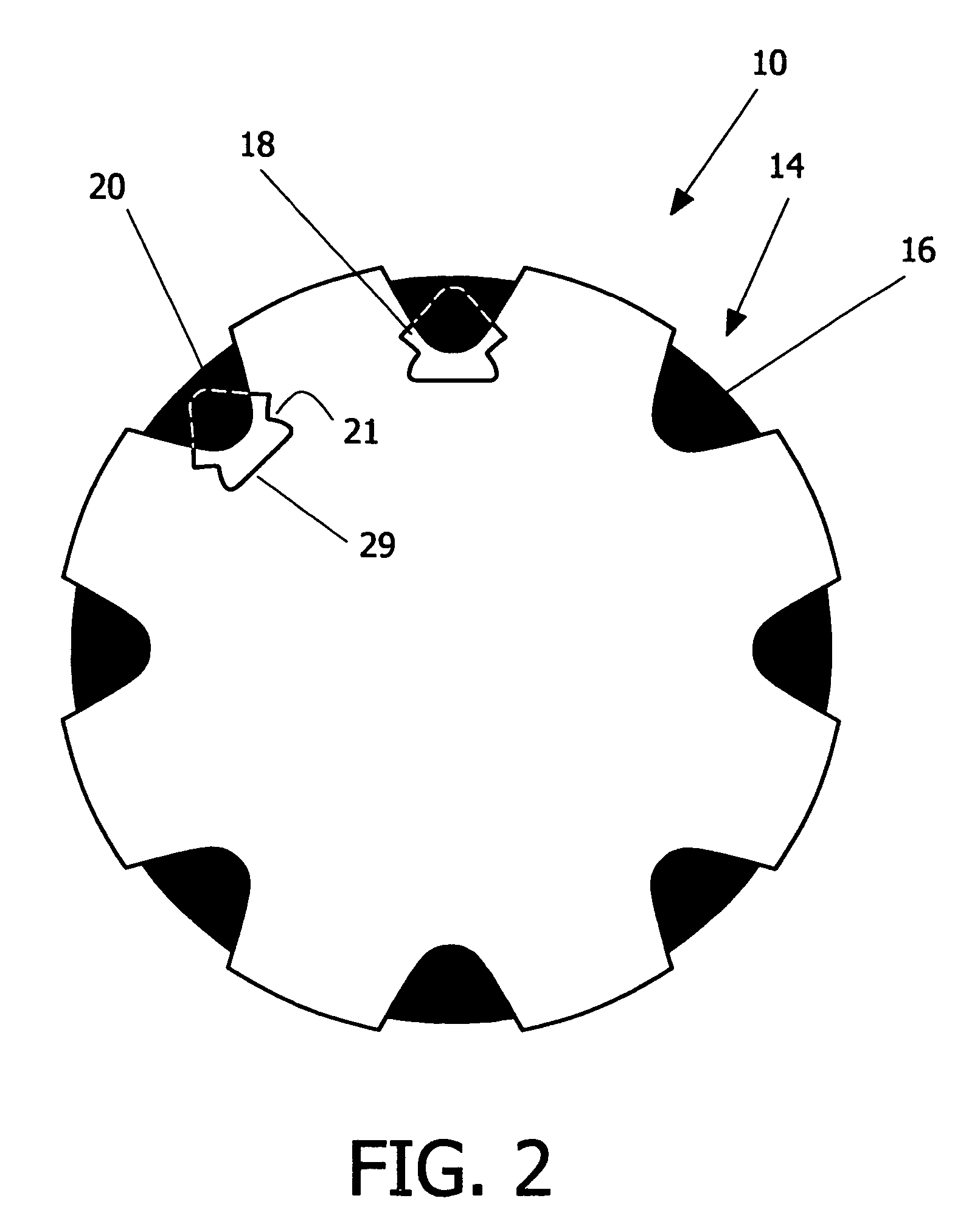

[0033] According to the present invention, a blank is formed from a hard material and a superhard cutting material. The blank having a number of pockets for receiving superhard cutting material and a superhard cutting material therein. An illustrative embodiment of such a blank is shown in FIG. 1. As shown in FIG. 1, the blank 10 comprises a substrate 12 of a hard material having a plurality of pockets 14 formed therein. While the blank 10 is illustrated as having a disk-like shape, other geometries are clearly possible, such as a polygon. It is also possible to form a through-hole in the blank 10, which may facilitate handling. Similarly, the pockets 14 may have a size, location, distribution, and number with differ from the illustrated embodiment. For example, the pockets 14 are shown as having a curved or arcuate shape. However, other shapes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com