Lubricant supported electric motor

a technology of electric motors and lubricants, applied in the direction of mechanical equipment, gearing details, magnetic circuit shapes/forms/construction, etc., can solve the problems of difficulty in spindle support, lack of mechanical robustness of on-wheel electric motors, lack of efficiency in converting electric power to mechanical power, etc., to reduce the torsional stiffness of output torque, increase the rotor, and produce additional torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

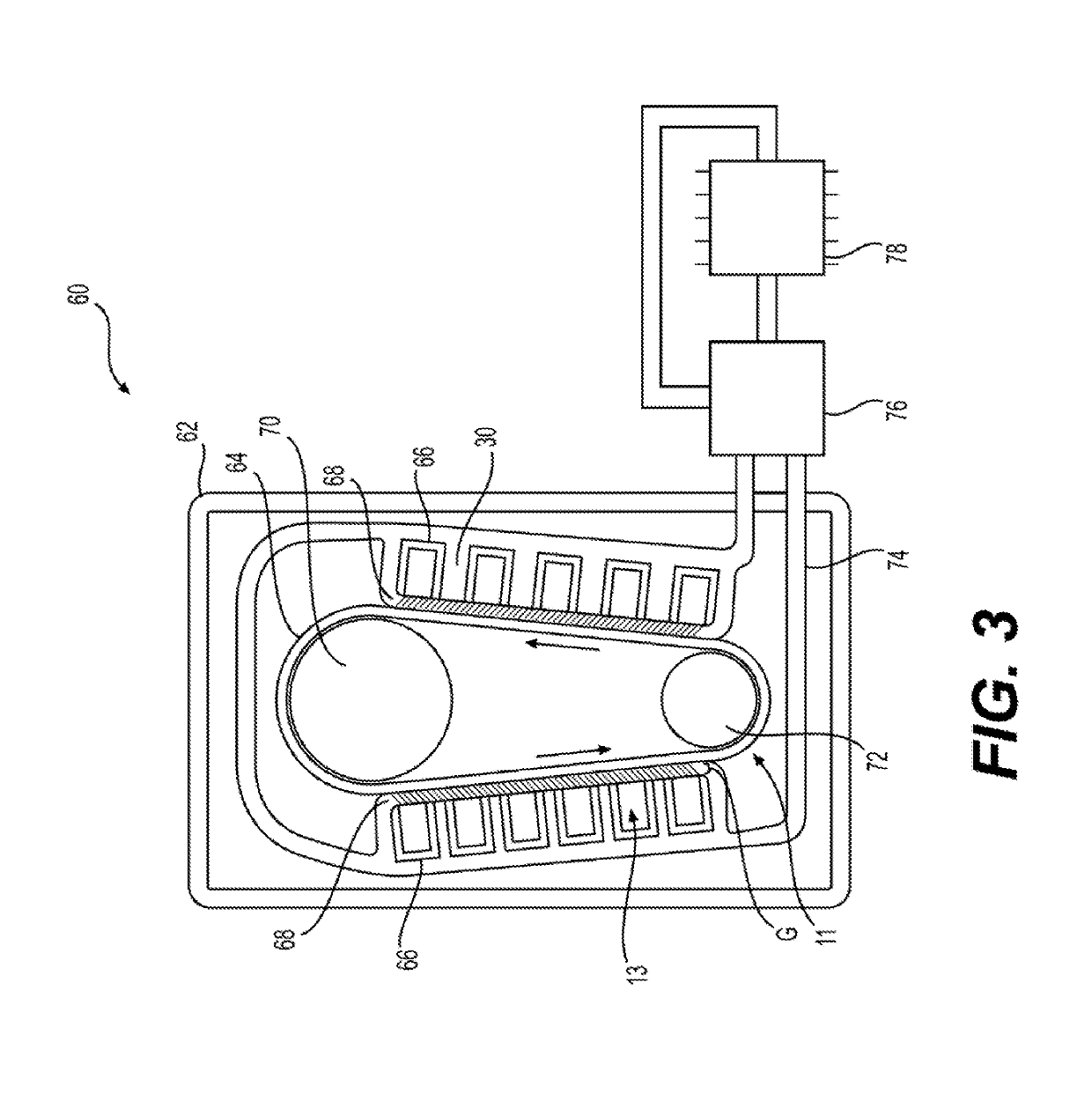

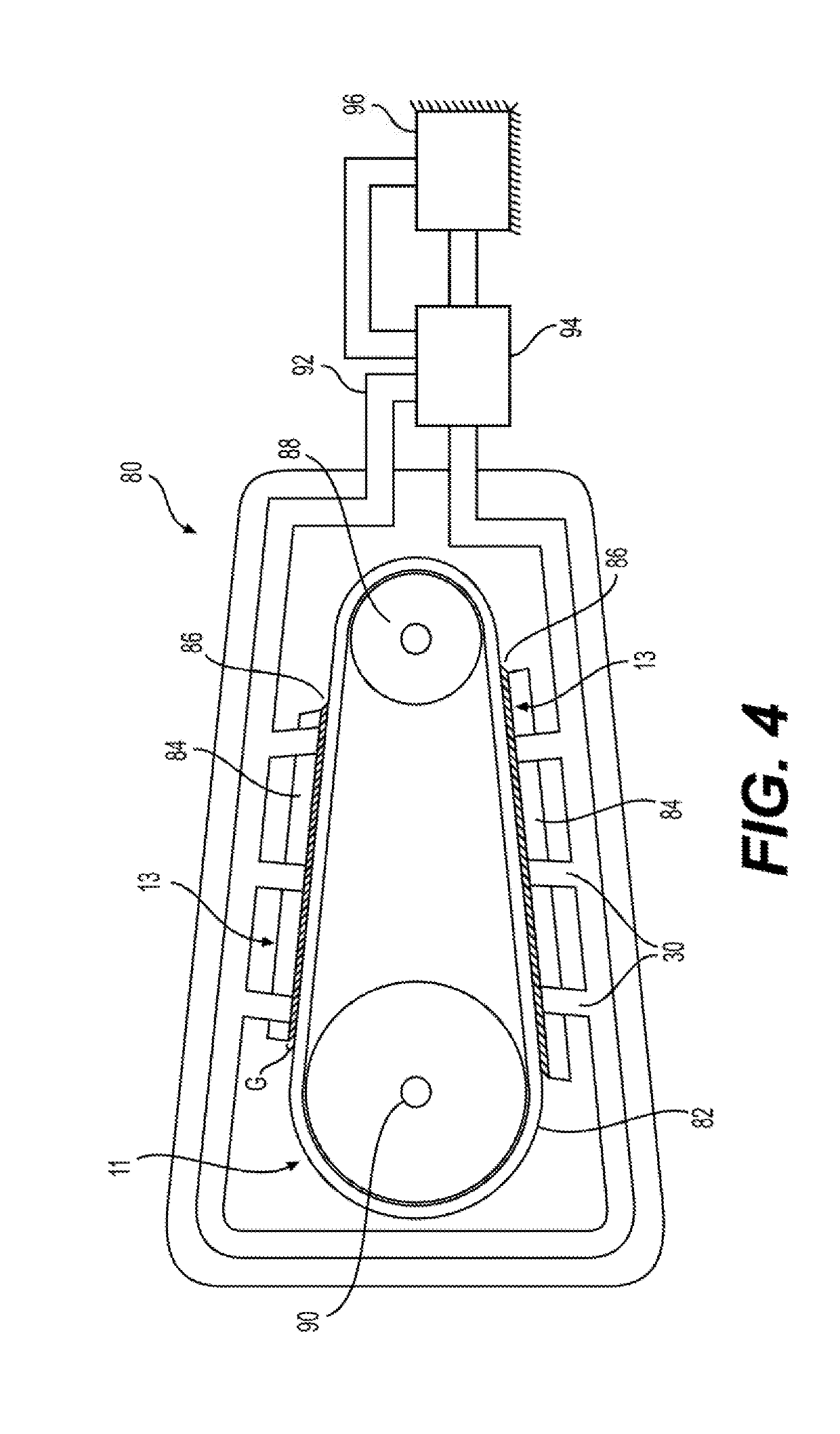

[0020]Exemplary aspects will now be described more fully with reference to the accompanying drawings. In particular, a number of non-limiting aspects of vehicle driveline components with a wheel support with or without an end gear reduction unit integrated with a wheel end motor is provided so that this disclosure will be thorough and will fully convey the true and intended scope to those who are skilled in the art. It will be apparent to those skilled in the art that specific details need not be employed, that example aspects may be embodied in many different forms and that neither should be construed to limit the scope of the disclosure. It should also be appreciated that the present disclosure can be utilized in connection with other types of vehicle components not described fully herein.

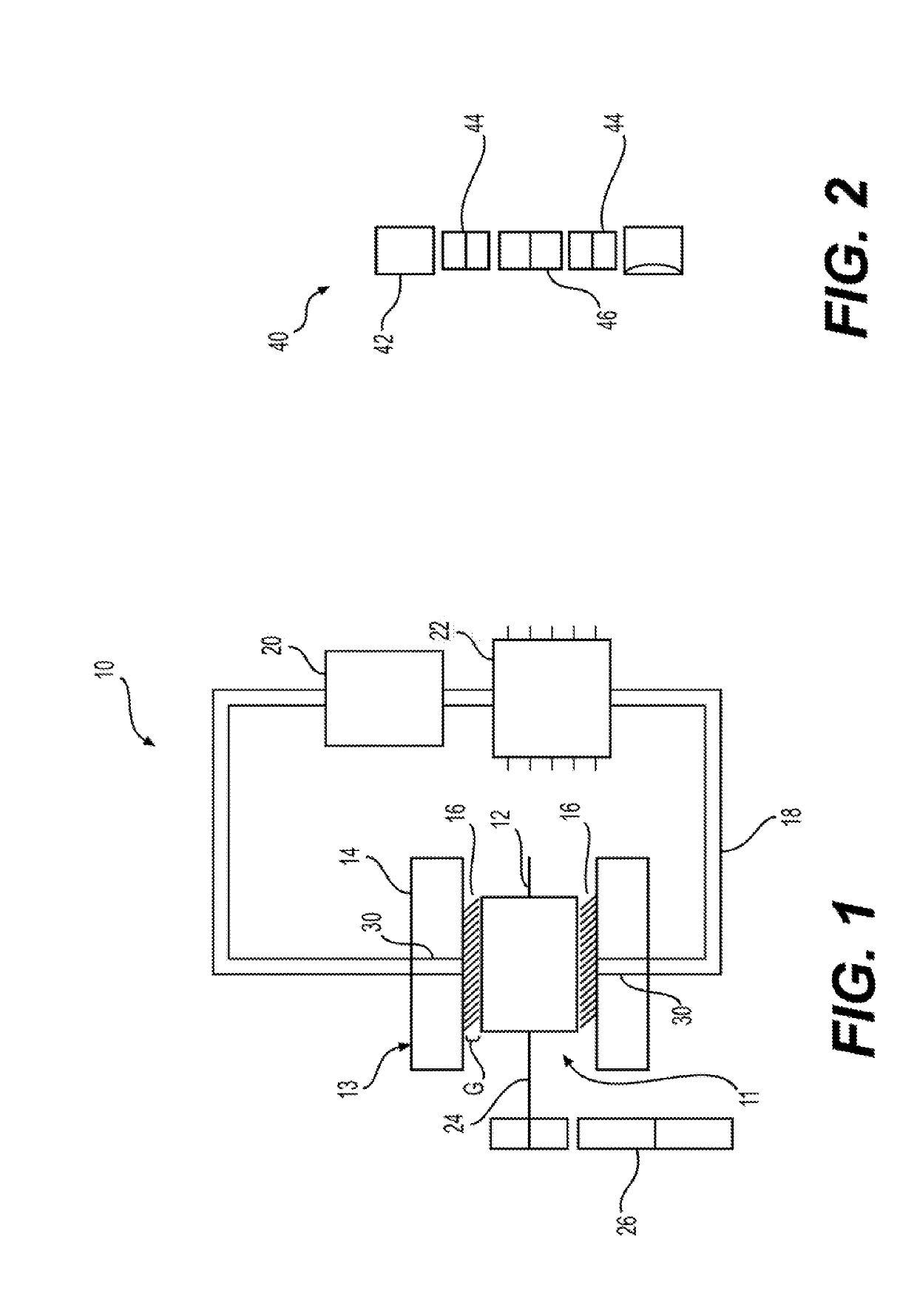

[0021]Referring to FIG. 1, a lubricant supported electric motor 10 is shown having a movable member 11 and a static member 13. The movable member 11 may be configured as a rotor 12 and the static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com