Rubber polyurethane line

a polyurethane line and rubber technology, applied in the field of liners, can solve the problems of limited functional life of steel pipes, persistent challenges for rubber liners, and expensive and problematic procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

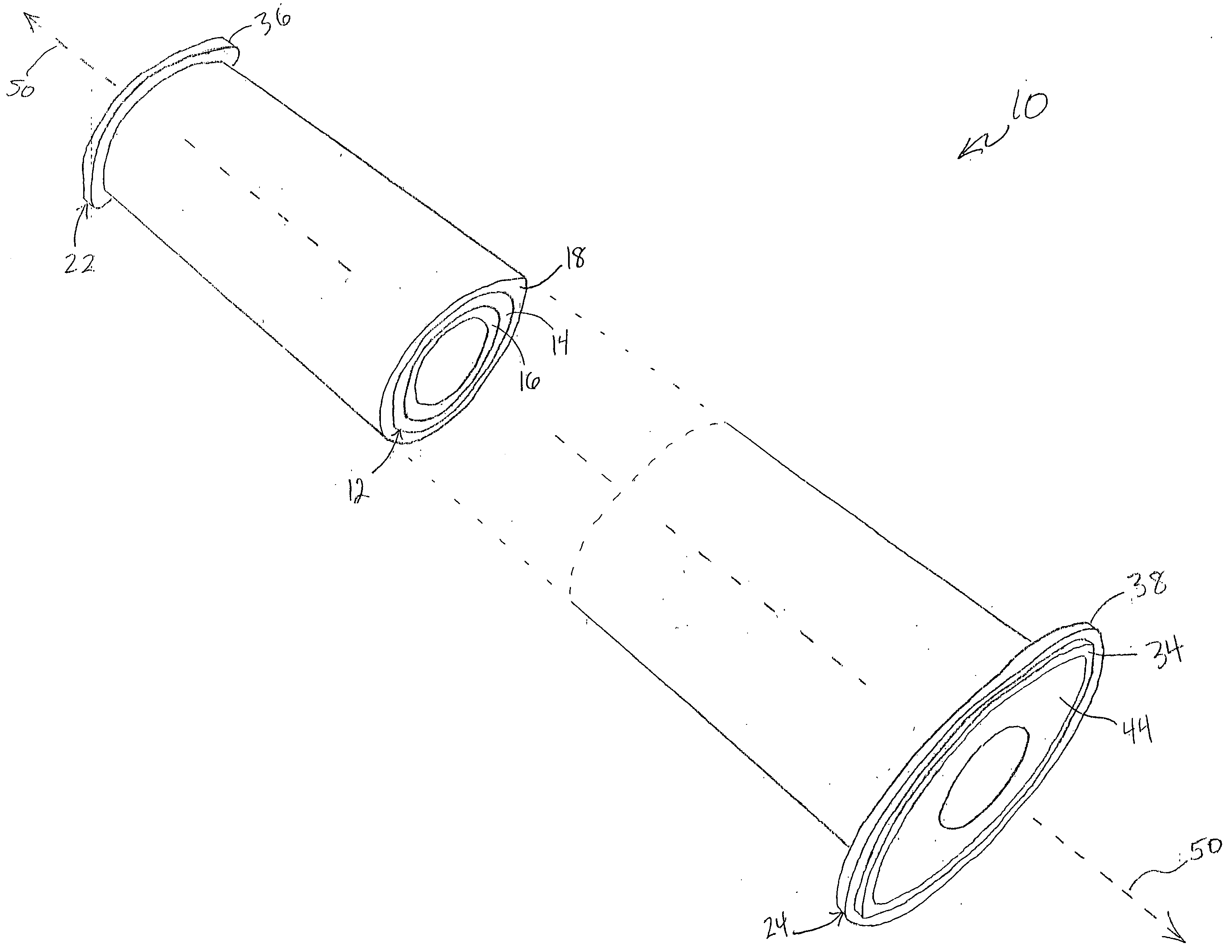

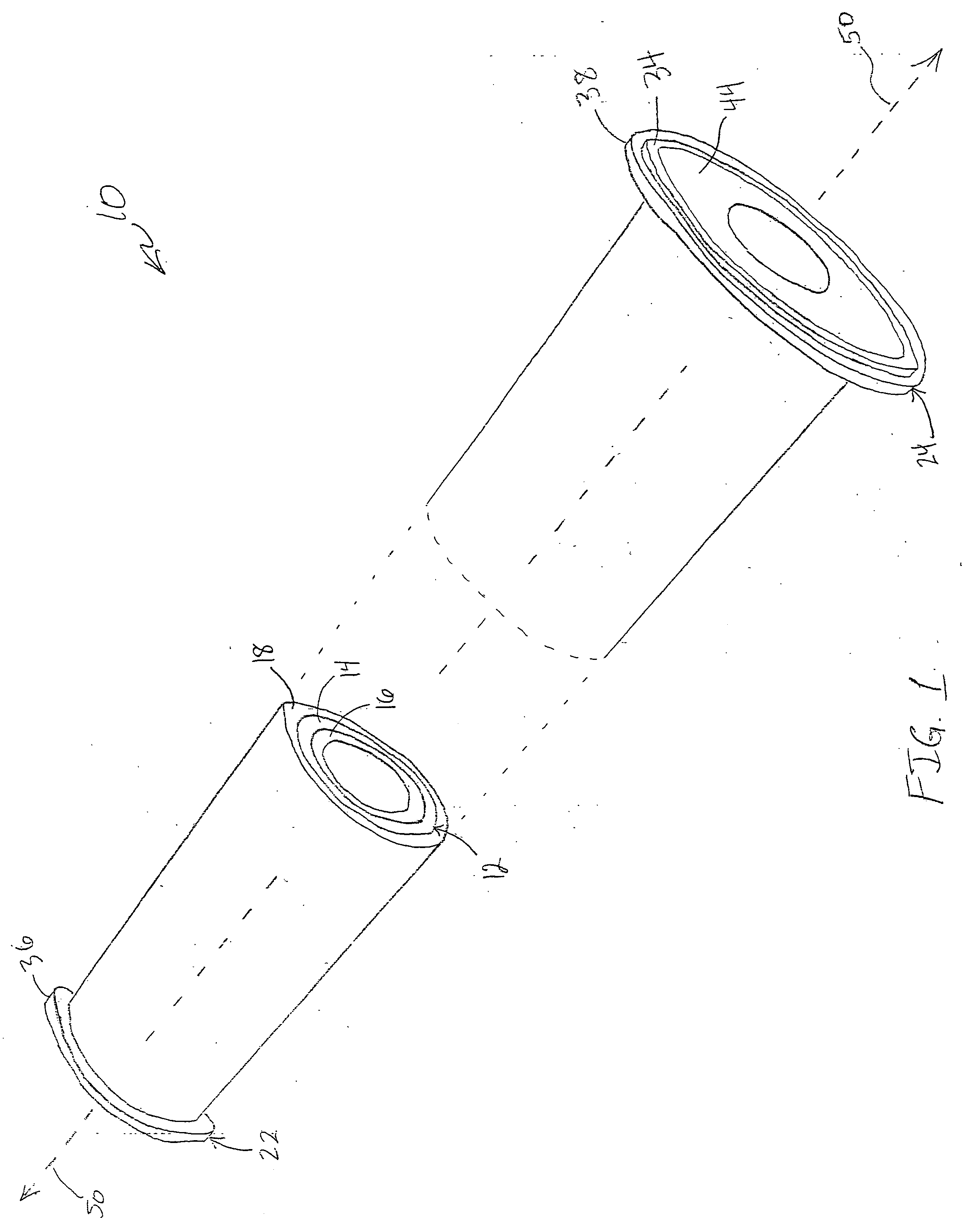

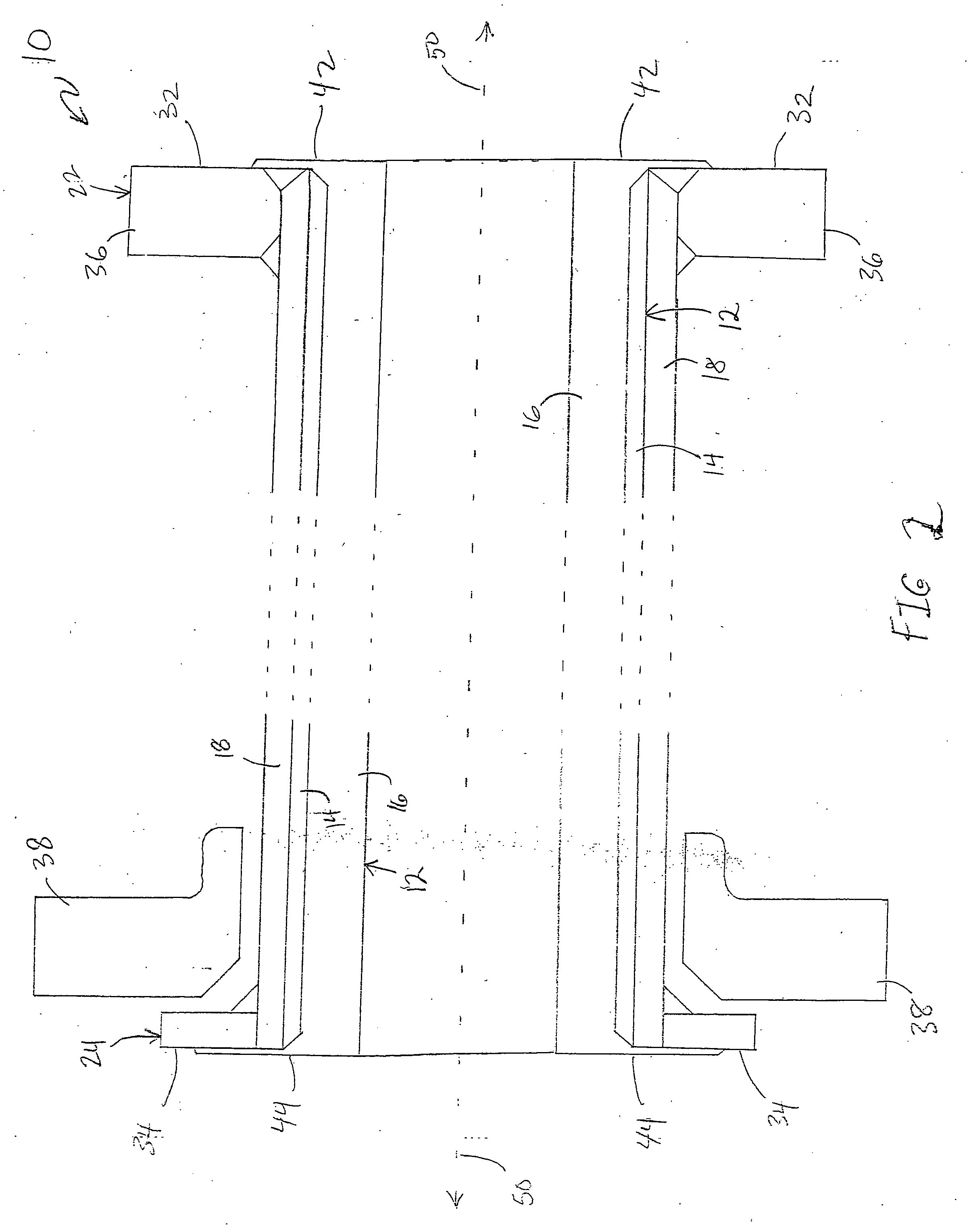

[0017]FIG. 1 illustrates a perspective, cutaway view of a lined pipe 10 with liner 12, according to one illustrative embodiment. FIG. 2 illustrates a side, cross sectional, cutaway view of the lined pipe 10 with liner 12, according to one illustrative embodiment. Liner 12 includes both a rubber liner portion 14 adhered to an inner surface of pipe portion 18, and a polyurethane liner portion 16 adhered to and covering rubber liner portion 14. Lined pipe 10 has a first end 22 and a second end 24 opposite the first end 22. First end 22 includes pipe end surface 32 and polyurethane end surface 42 (both depicted only in FIG. 2) and slip-on flange 36. Second end 24 includes pipe end surface 34, polyurethane end surface 44, and lap joint flange 38. FIG. 2 also depicts end caps 66 and 68 for attaching to first end 22 and second end 24, respectively. Slip-on flange 36, lap joint flange 38, and end caps 66 and 68 are a few examples of a wide variety of flanges, tooling, and other supplemental...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com