Additive manufacturing method for parts with thin wall structure based on SLM process

A thin-walled structure, additive manufacturing technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of high processing cost, cumbersome process, increased part design work, etc., to ensure the success rate and size. Stability, simple process design method, effect of reducing the cost of additive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

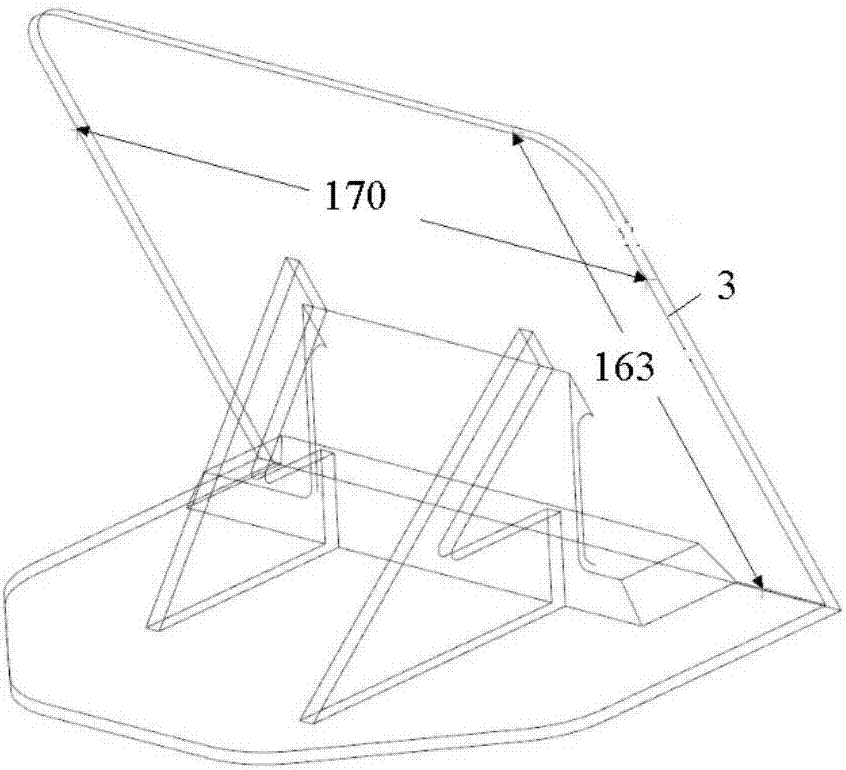

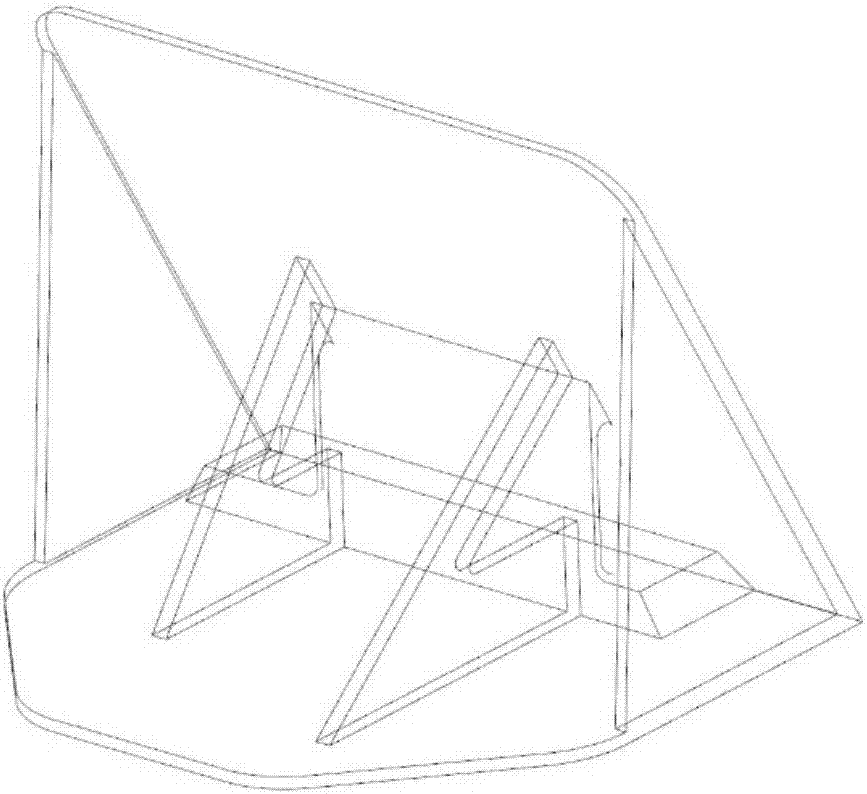

[0033] After the parts with thin-walled structure are optimally placed, the schematic diagram of the structure is as follows figure 1 As shown, this product is a connecting corner box, which is used to fix and connect two independent other parts. The size of the whole part is 170mm×163mm×132mm, and the angle between the thin-walled structure and the horizontal plane is 60°. The technical difficulty lies in its 3mm Thick and thin-walled structures are difficult to form and are easily deformed during the forming process; parts are made of aluminum alloy;

[0034] The part is manufactured using the additive manufacturing method of the SLM process, the steps of which include:

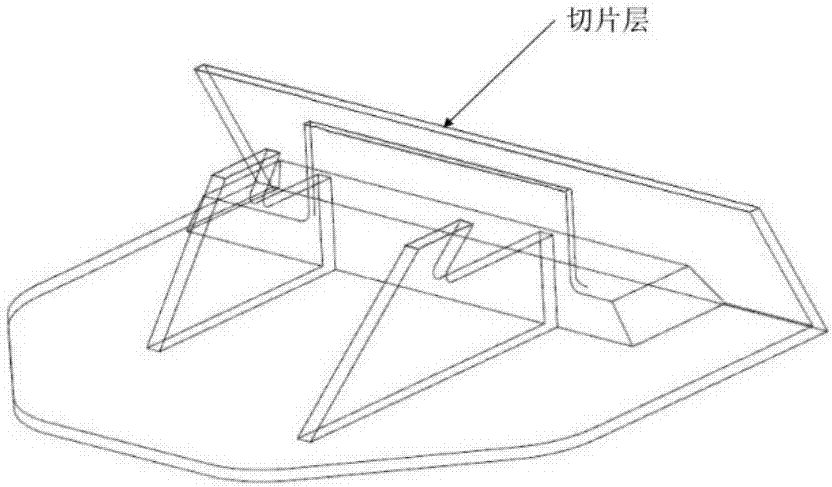

[0035] (1) Add process support to the thin-walled part of the part with thin-walled structure. After adding the process support, the slice layer of the thin-walled part changes, by image 3 The Type I slice layer in becomes Figure 4 The U-shaped slice layer in , to get the process model of the parts with...

Embodiment 2

[0040] After the parts with thin-walled structure are optimally placed, the schematic diagram of the structure is as follows Figure 5 As shown, this product is a fan blade with fins facing inward. Its function is to use high-speed rotation to generate compression to increase gas pressure. The size of the entire part is Among them, the angle between the thin-walled structure and the horizontal plane is 77° to 45°, and the technical difficulty is that the thin-walled structure with a gradual thickness of 0.5 to 1mm is difficult to form and easy to deform during the forming process; the parts are made of titanium alloy materials;

[0041] The part is manufactured using the additive manufacturing method of the SLM process, the steps of which include:

[0042] (1) Add process support to the thin-walled part of the part with thin-walled structure. After adding the process support, the slice layer of the thin-walled part changes, by Figure 7 The Type I slice layer in becomes Fi...

Embodiment 3

[0047] After the parts with thin-walled structure are optimally placed, the schematic diagram of the structure is as follows Figure 9 As shown, this product is a fan blade with outward fins. Its function is to use high-speed rotation to generate air pressure to increase the gas pressure. The size of the entire part is Among them, the angle between the thin-walled structure and the horizontal plane is 77° to 45°, and the technical difficulty is that the thin-walled structure with a gradual thickness of 0.5 to 1mm is difficult to form and easy to deform during the forming process; the parts are made of titanium alloy materials;

[0048] The part is manufactured using the additive manufacturing method of the SLM process, the steps of which include:

[0049](1) Add process support to the thin-walled part of the part with thin-walled structure. After adding the process support, the slice layer of the thin-walled part changes, by Figure 11 The Type I slice layer in becomes Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com