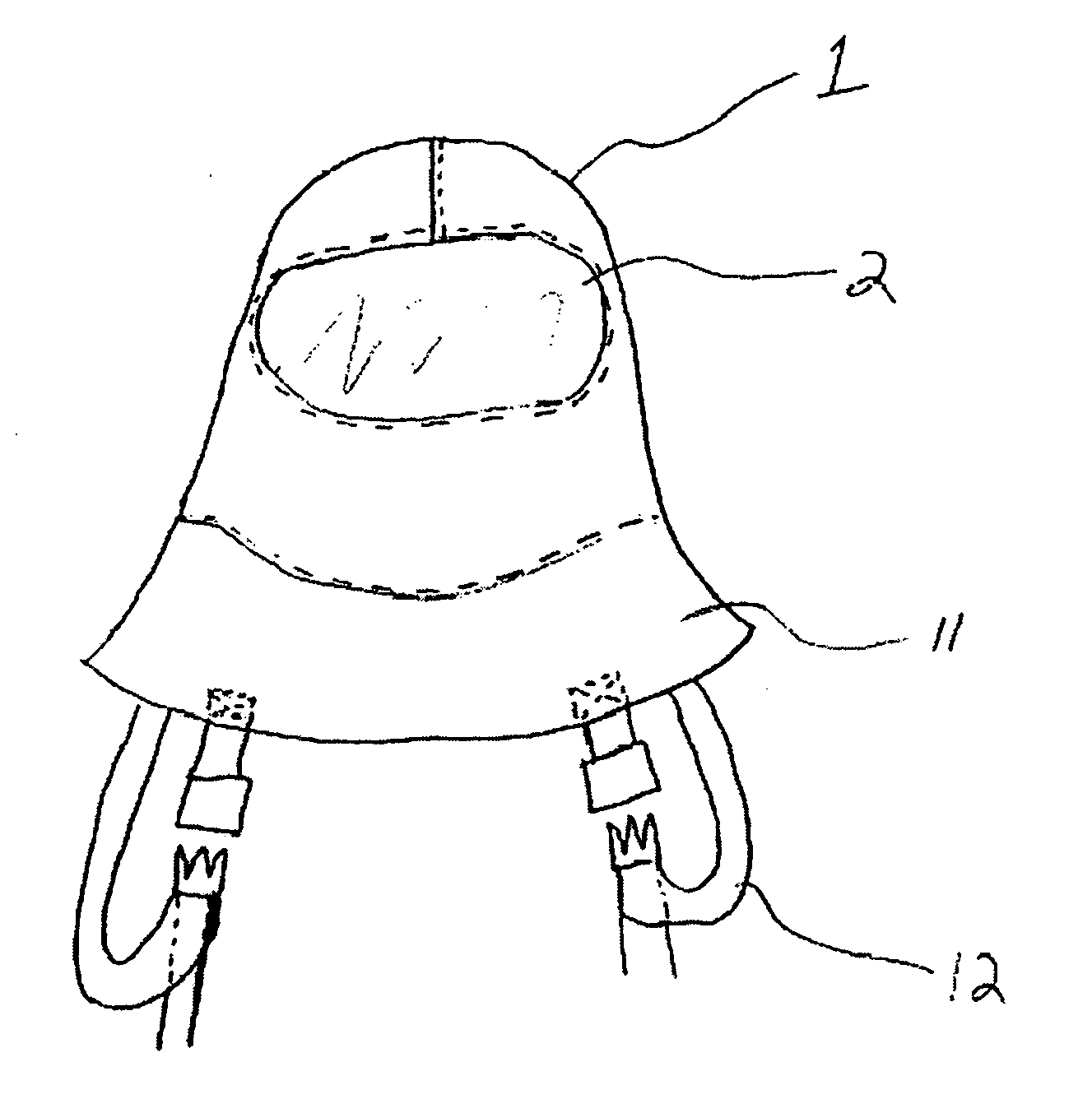

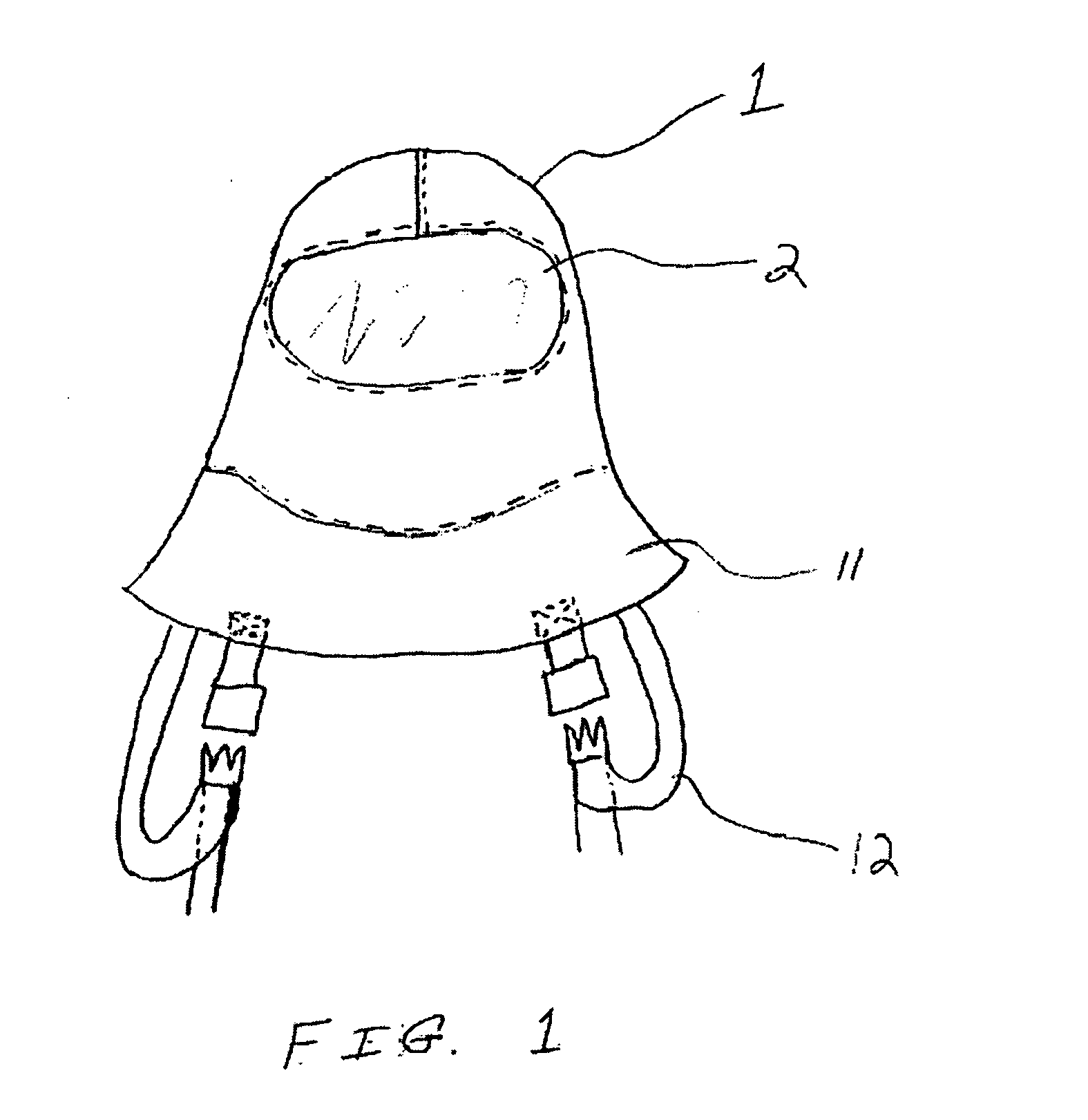

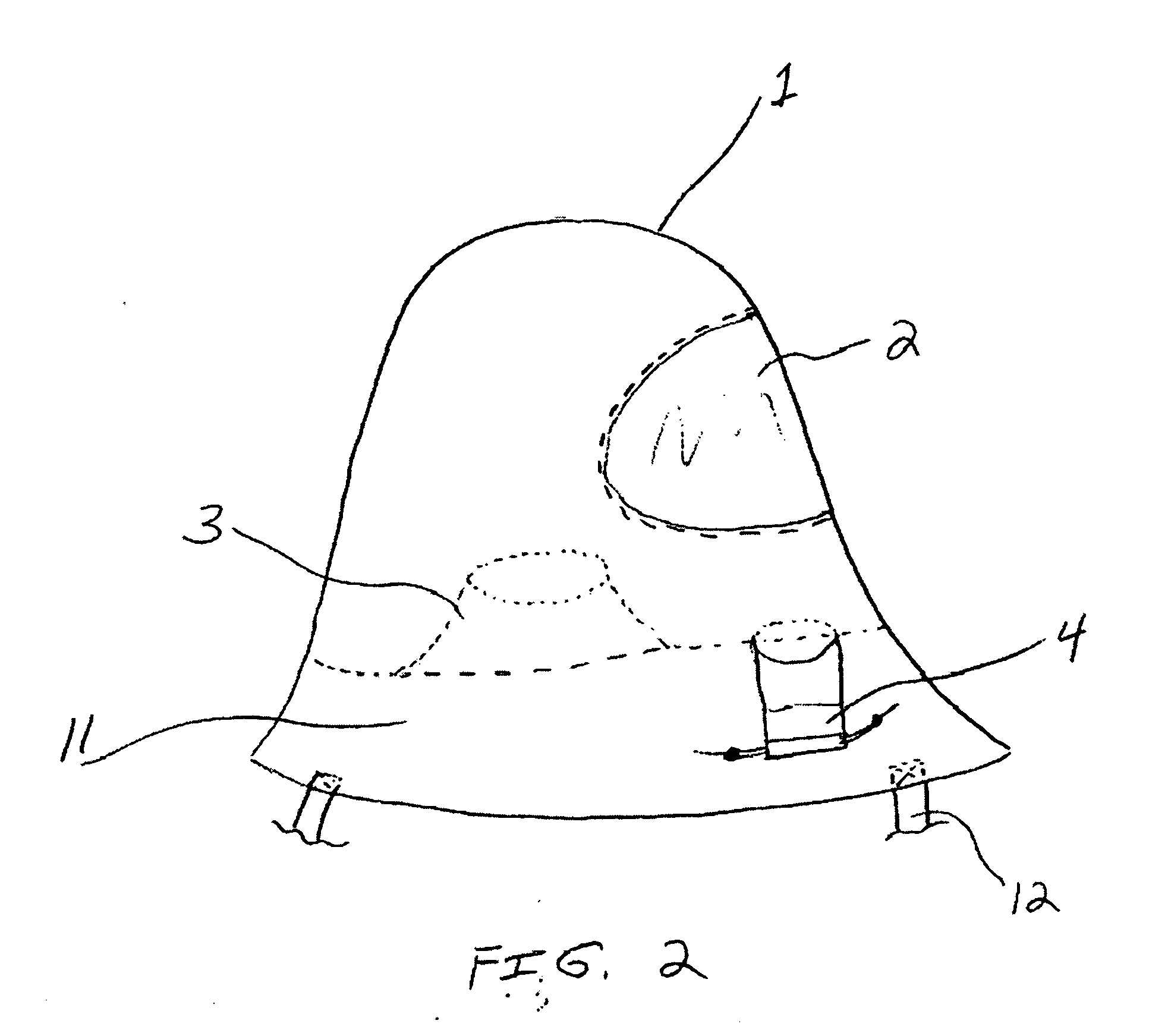

Chemical and biological protective hood assembly

a technology of protective hoods and hoods, applied in protective garments, headwear caps, hats, etc., can solve the problems of restricting user movement and visibility, wearing completely decontaminated, and non-encapsulating designs that offer complete skin protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0053] A hood was constructed of three-layer chemical / biological protective fabrics, a chemical / biological protective seam tape, a latex rubber was used as neck sealing means, an optically clear polyvinyl chloride (PVC) film was used as the visor, a 0.045″×1″ open-cell foam rubber tape was used as the air line sealing means, a nylon cording and strapping with locking fasteners was used as the securing means for air line sealing means. The three-layer chemical / biological protective fabrics consisted of a fabric construction from W. L. Gore & Associates (part number ECAT 614001B). Chemical / biological protective seam tape from W. L. Gore & Associates (part number 6HSAJ025BLKBX) was used to seal sewn-together seams. Latex rubber was affixed at the head passthrough as the neck sealing means (part number 30003 / 1725AS102-4, Formco, Inc). The optically clear PVC visor had a nominal thickness of 0.080 inches was supplied by McMaster Carr (part number 87875K37).

[0054] Once the fabric, PVC fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com