Vacuum cleaner

a vacuum cleaner and vacuum cleaner technology, applied in the field of vacuum cleaners, can solve the problems of vacuum cleaners having problems in replacing filters, and achieve the effect of cleaning the inside of dust collectors with ease, enabling cleaning and replacing filters with eas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

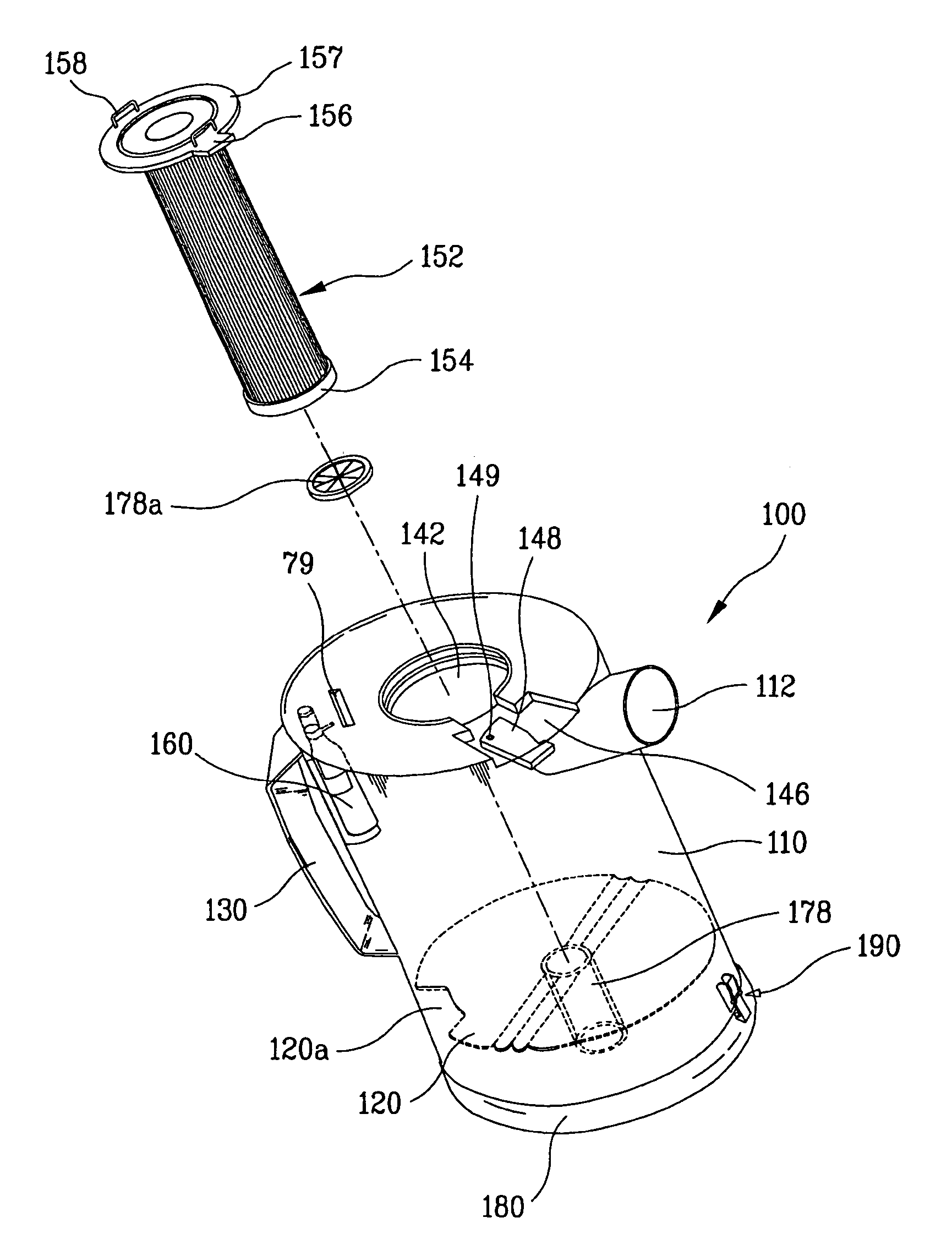

[0097] As illustrated in FIGS. 8 to 10, the dust collector assembly in accordance with the present invention includes a dust collector 110, a filter 52, and a lower cover 180.

[0098] In this case, an outside diameter of the separation plate 220 is formed to be smaller that the inside diameter of the dust collector 110. Accordingly, a gap 220a is formed between the separation plate 220 and the dust collector 110. The gap 220a plays the same role as the pass through hole 120a. In other words, impurities with large masses among the impurities drawn into the dust collector 110 are accumulated in the lower inner space of the dust collector 110.

[0099] It is desirable that the separation plate 220 and the lower cover 180 are formed as a single body. In this case, as illustrated in FIG. 10, the separation plate 220 rotates together with the lower cover 1880 and escapes to the outside of the dust collector 110 when the lower surface of the dust collector 110 is opened. At this time, for prev...

first embodiment

[0101] As illustrate in FIG. 11, a discharge tube cover 178a is provided on the upper surface of the second discharge tube 178. The discharge tube cover 178a has a same structure as that in the aforementioned

[0102] Hereinafter, the operation of the vacuum cleaner in accordance with the present invention will be described as follows.

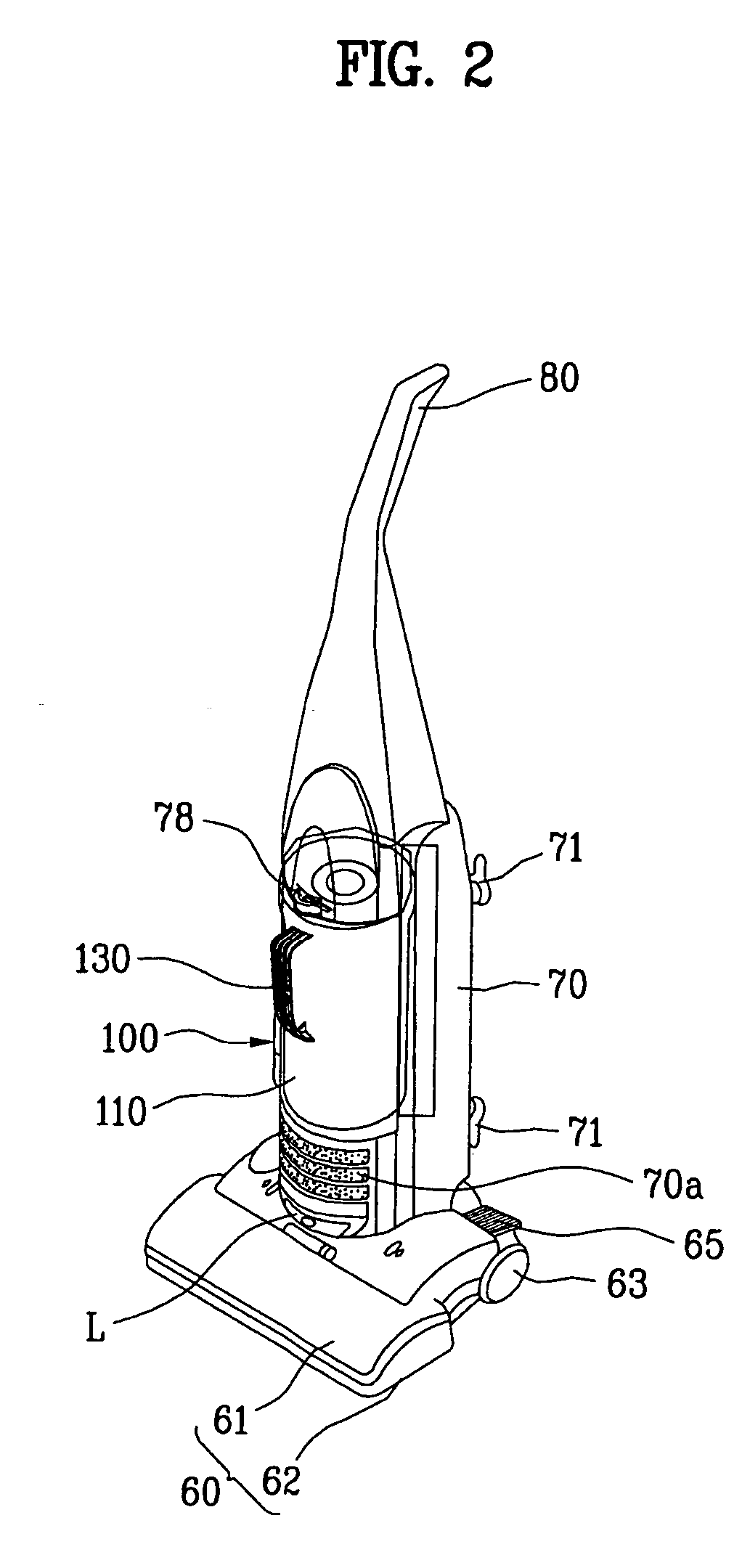

[0103] First, when the vacuum cleaner is operated, a suction force is transmitted to a suction nozzle 60 by the operation of a motor (Not shown) built in the body 70. Accordingly, air with impurities is drawn in through an inlet 62a of the suction nozzle 60.

[0104] The air is flowed into the dust collector 110 through an inflow tube 74 coupled with the inlet 62a and a suction pipe 112 formed on an outer surface of the dust collector.

[0105] In this case, impurities with large masses among the impurities contained in the air are accumulated in the lower inner space of the dust collector 120 through the pass through hole 120a or the gap 220a, and the impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com