Floor located vehicle container holder

a vehicle and container technology, applied in the field of vehicle container holders, can solve the problems of limiting the access to storage, spilling liquid, and much to be desired, and achieve the effects of reducing manufacturing costs, reducing the center of gravity of the container within the vehicle, and reducing the range of adjustment/varian

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

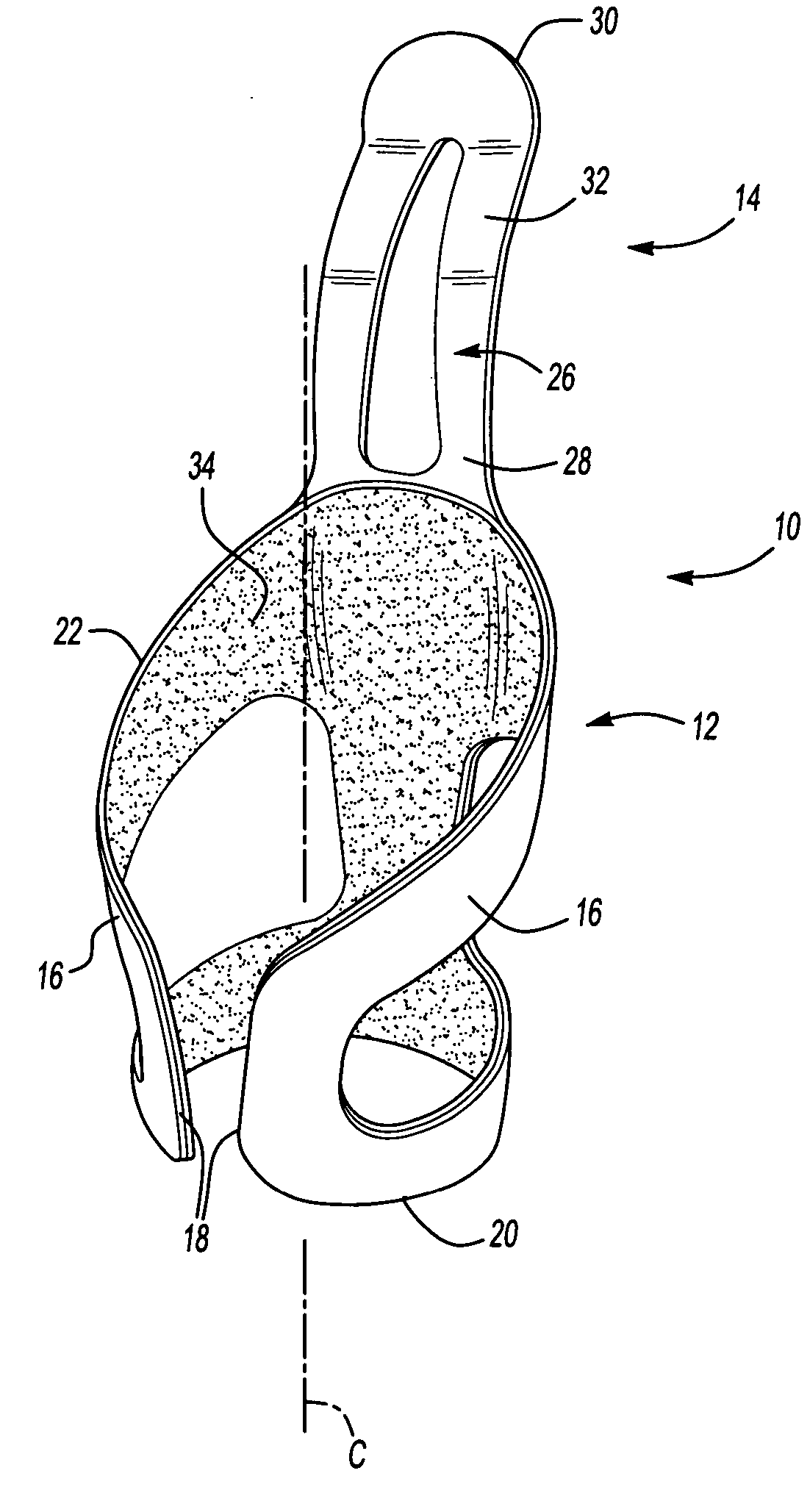

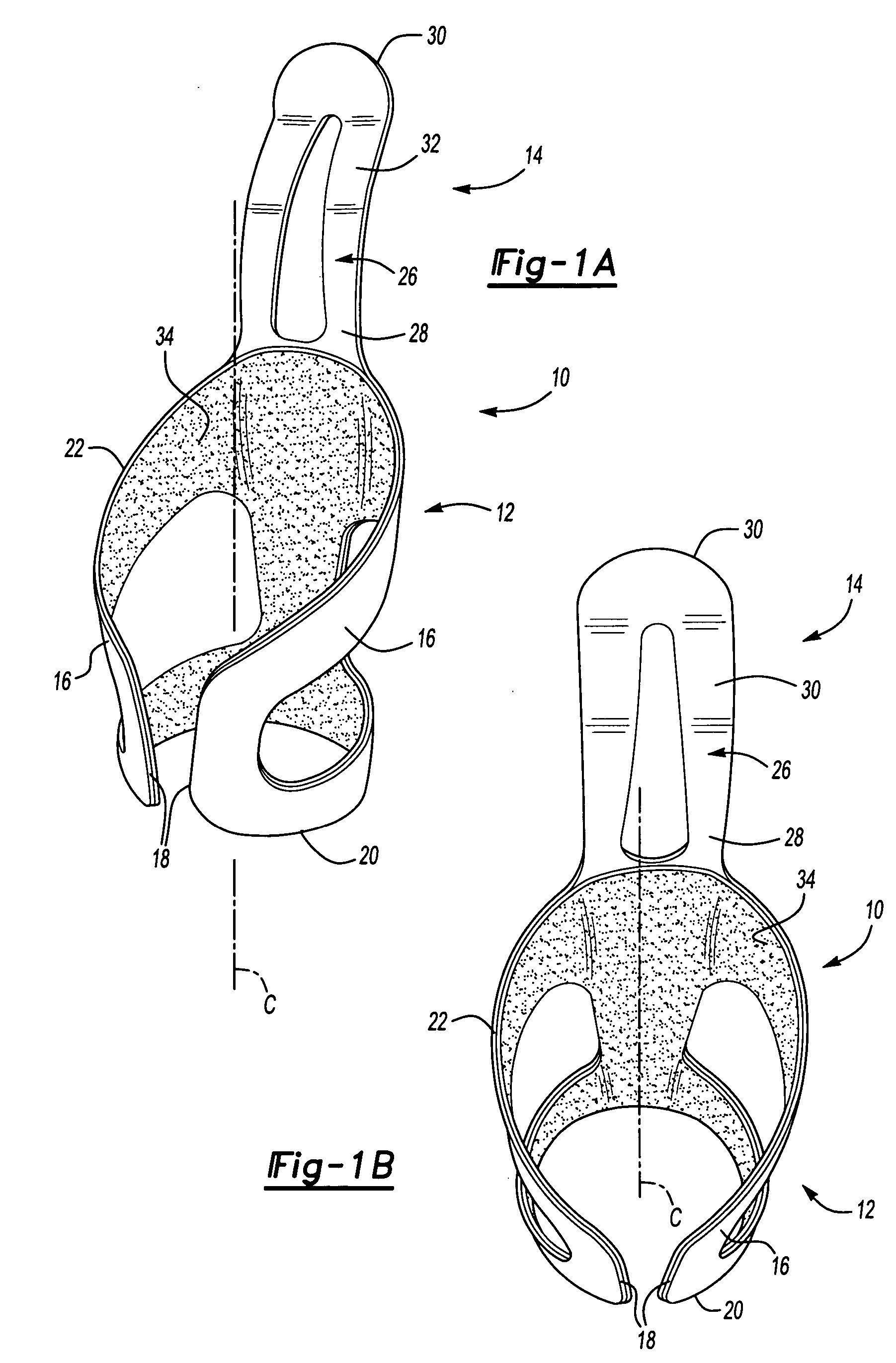

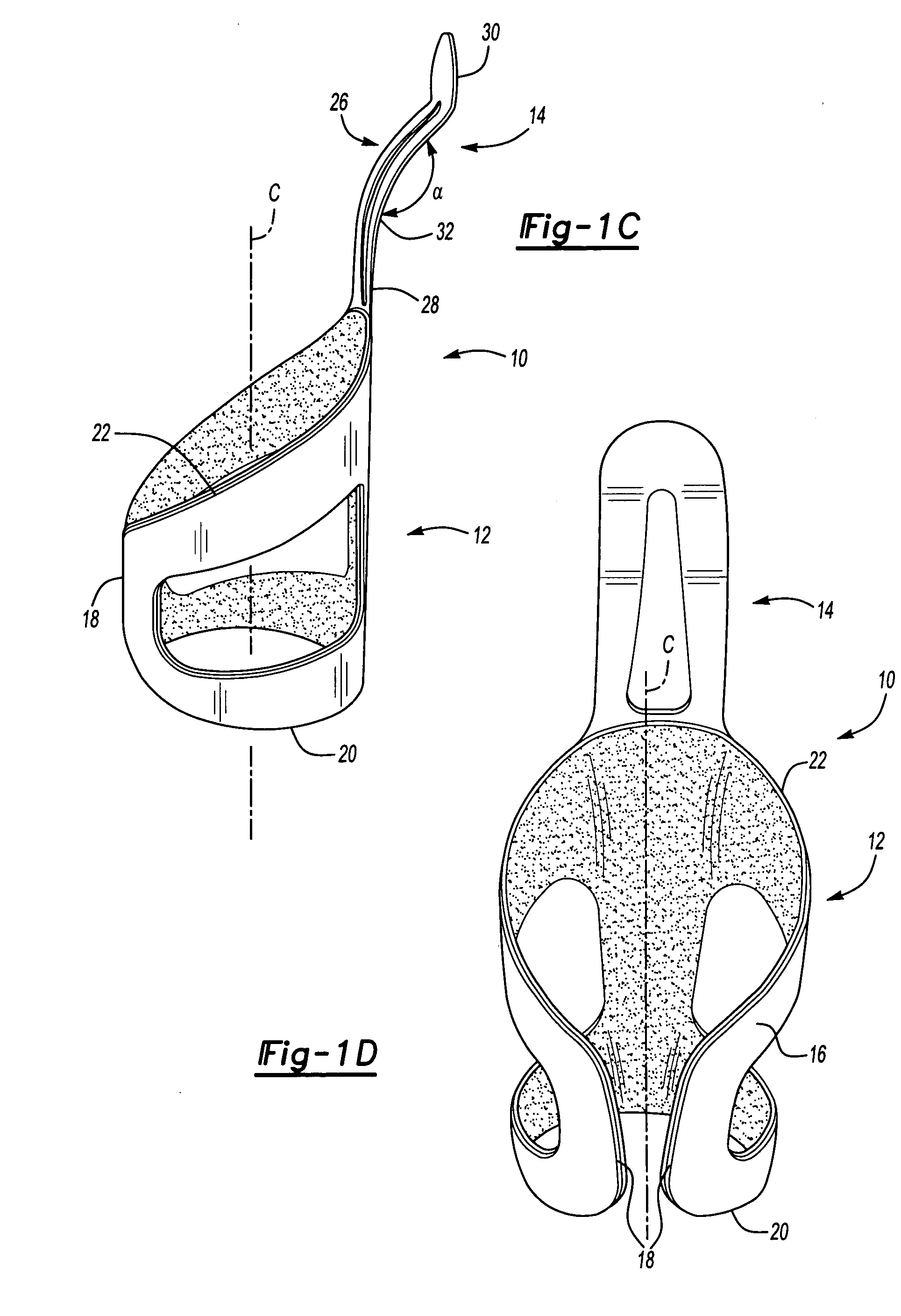

[0036]FIGS. 1A-1E illustrate a general perspective view of a vehicle container holder 10 designed according to the present invention. The container holder 10 generally includes a bottomless container retention section 12 and a mounting section 14.

[0037] The container retention section 12 defines a container axis C along which a container is received (FIG. 3). The container retention section 12 includes arms 16 which at least partially surround the container axis C. Two arms 16 having arm ends 18, which do not meet, are preferred such that a cup handle H (FIG. 4) may be received therebetween; however, a single continuous arm is contemplated by the present invention.

[0038] The arms 16 are generally arcuate. The arms 16 are preferably of a frustro conical geometry (FIG. 1B) in which a lower portion 20 of the arms 16 defines a smaller perimeter than the upper portion 22 of arms 16. It should be understood that relative positional terms such as “forward,”“aft,”“upper,”“lower,”“above,”“...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com