Air water closet

a technology for air-conditioning closets and closets, which is applied in water installations, lavatory sanitory, constructions, etc., can solve the problems of ineffective ventilation of an entire room using a ventilator in the ceiling or in the toilet wall to exhaust air, and the process becomes too complex and technically too complex, so as to achieve effective elimination of the spread of foul odor and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

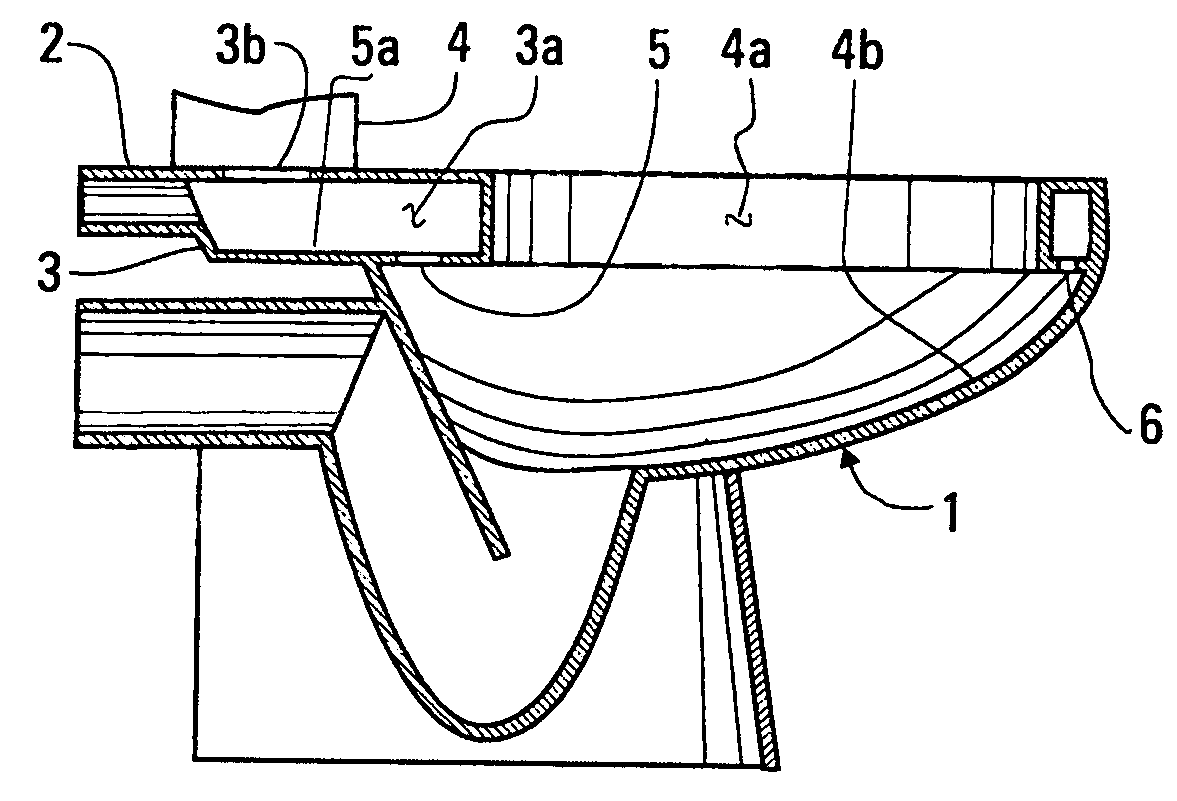

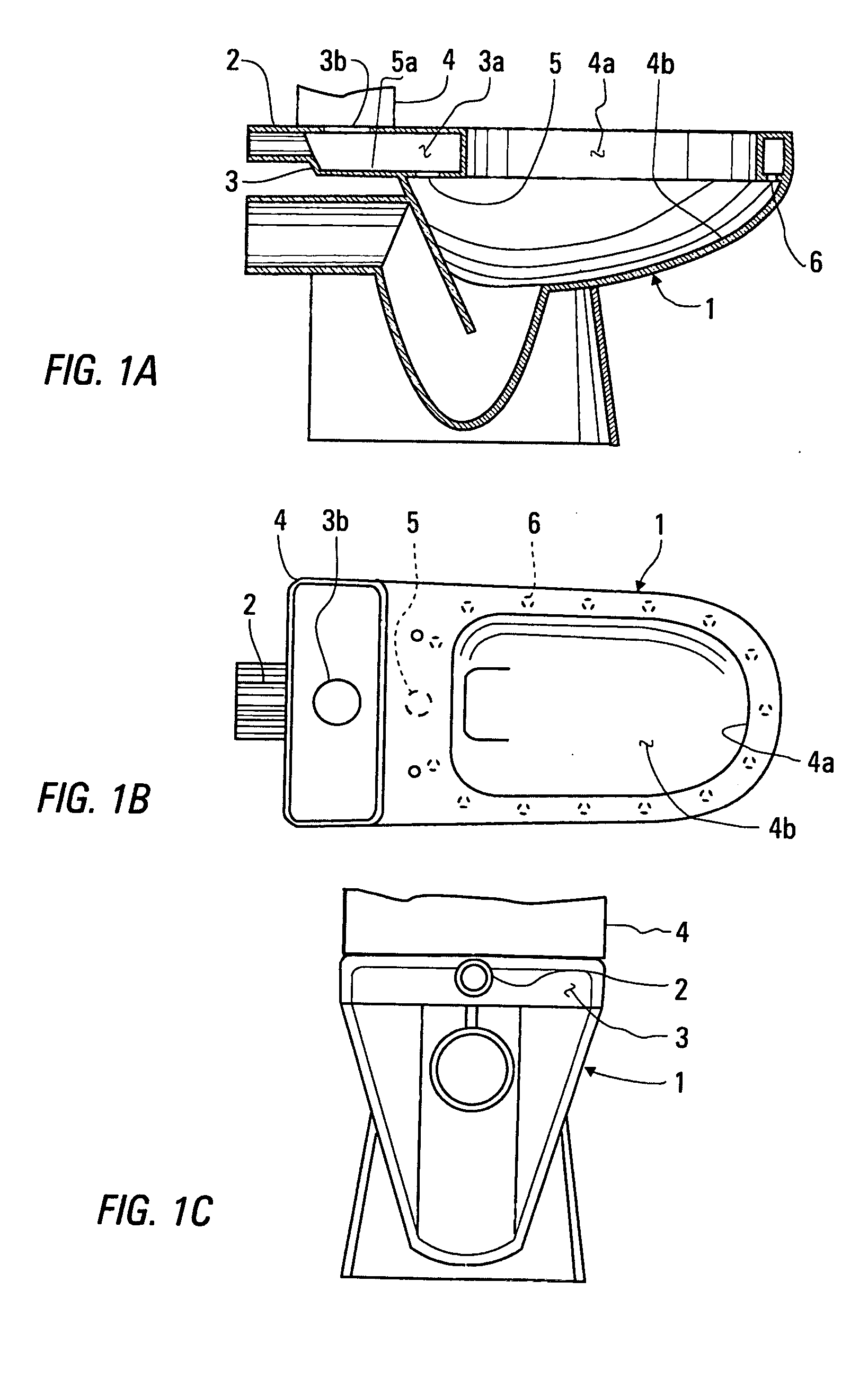

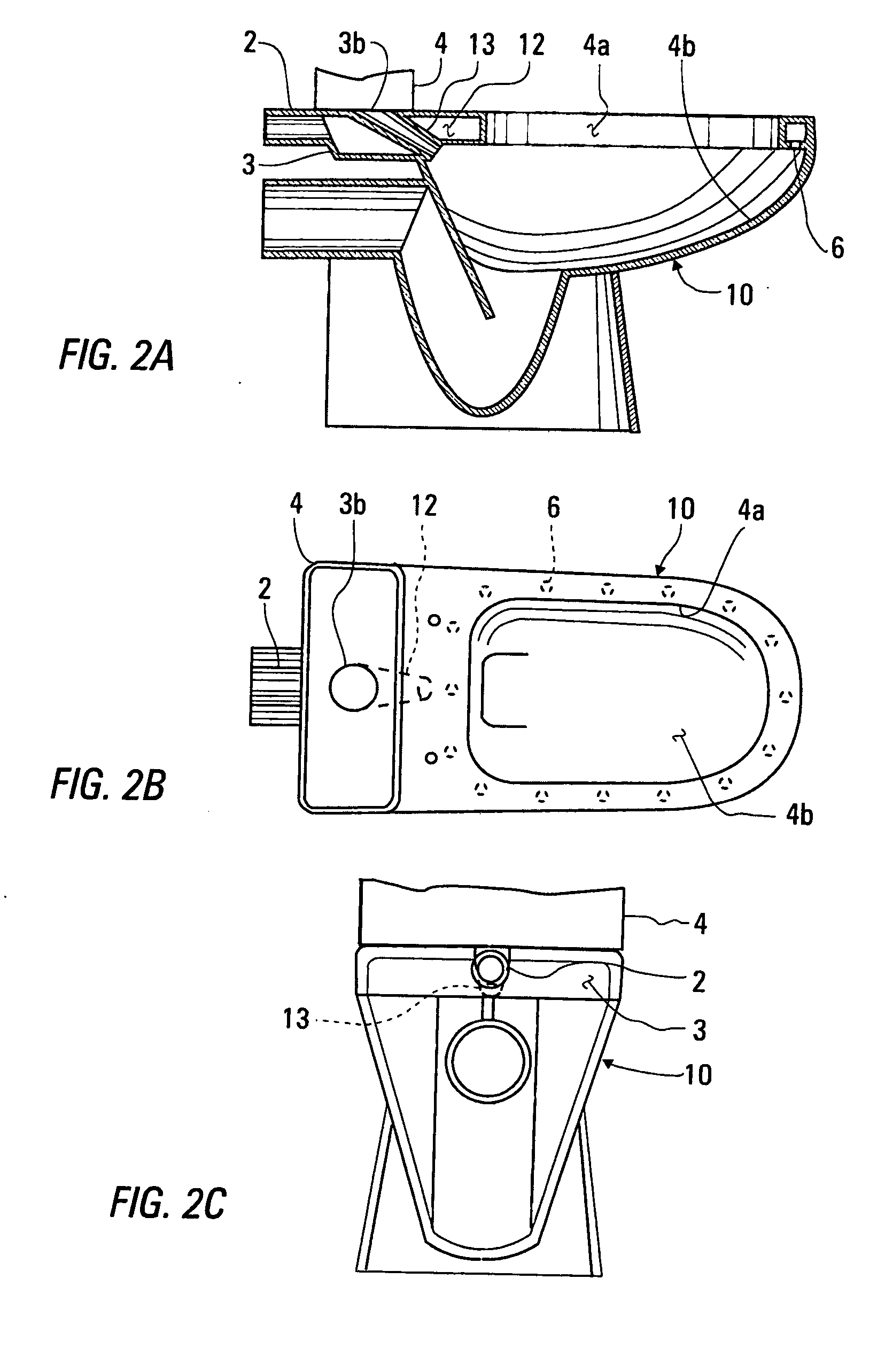

[0025] The three embodiments of the figures have a number of common elements, which are therefore accorded like reference numbers. Furthermore, each of the three embodiments includes a suction channel for sucking air from a bowl of the water closet to eliminate a foul odor and a rinsing channel providing water to rinse the bowl.

[0026] A water closet 1, built in accordance with the first embodiment of the invention will now be discussed, with reference being made to FIGS. 1A, 1B, and 1C, of which FIG. 1A is a longitudinal cross-sectional view, FIG. 1B is a plan view, and FIG. 1C is a rear elevation. According to the first embodiment, the suction and rinsing channels have common portions. The suction channel includes an exhaust tube 2 extending from the back portion 3 of the water closet opening into a first compartment 3a, which is shared with the rinsing channel to be used for rinsing the water closet 1, with water entering the compartment 3a through an aperture 3b from a tank 4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com