End member for a bone fusion implant

a bone fusion and end member technology, applied in the field of end members of bone fusion implants, can solve the problems of restoring the natural and affecting the normal anatomical length and shape of any long bone with a bone defect. , to achieve the effect of promoting bone fusion and restoring spinal anatomy and stability, the problem of the most difficult aspects of treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

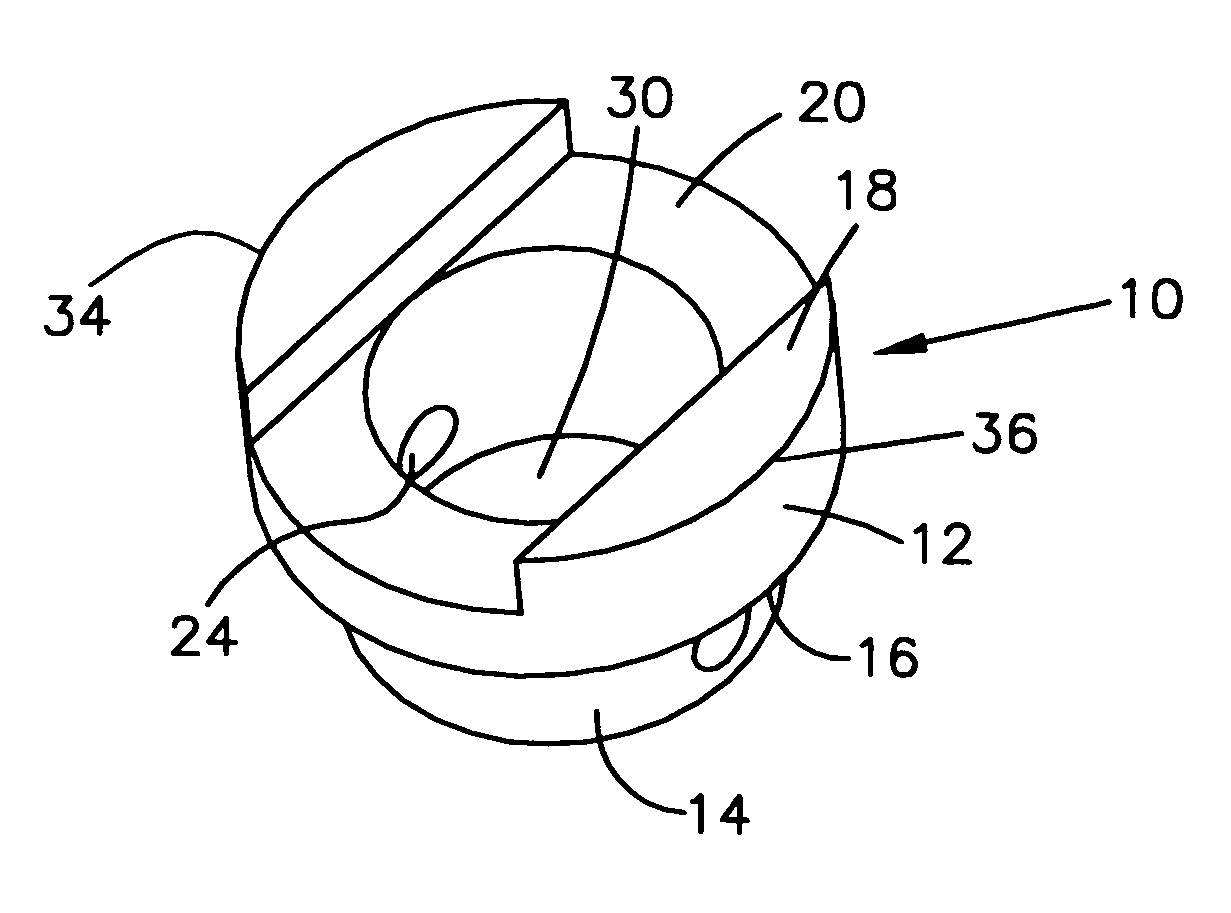

[0030]FIG. 1 shows an end member 10 according to the present invention. End member 10 has a first portion. 12 and a second portion 14. As first portion 12 is larger than second portion 14, a shoulder 16 is formed at the intersection between first and second portions 12, 14. A top surface 18 of first portion 12 is provided with a first slot 20 for accommodating surgical instrumentation such as holding, insertion, and / or distraction instruments. Top surface 18 is shown in FIG. 1 with a round shape. However, as will be evident from the other embodiments, top surface 18 can have any suitable shape. Preferably, top surface 18 has a shape that matches the shape of the bone it will contact.

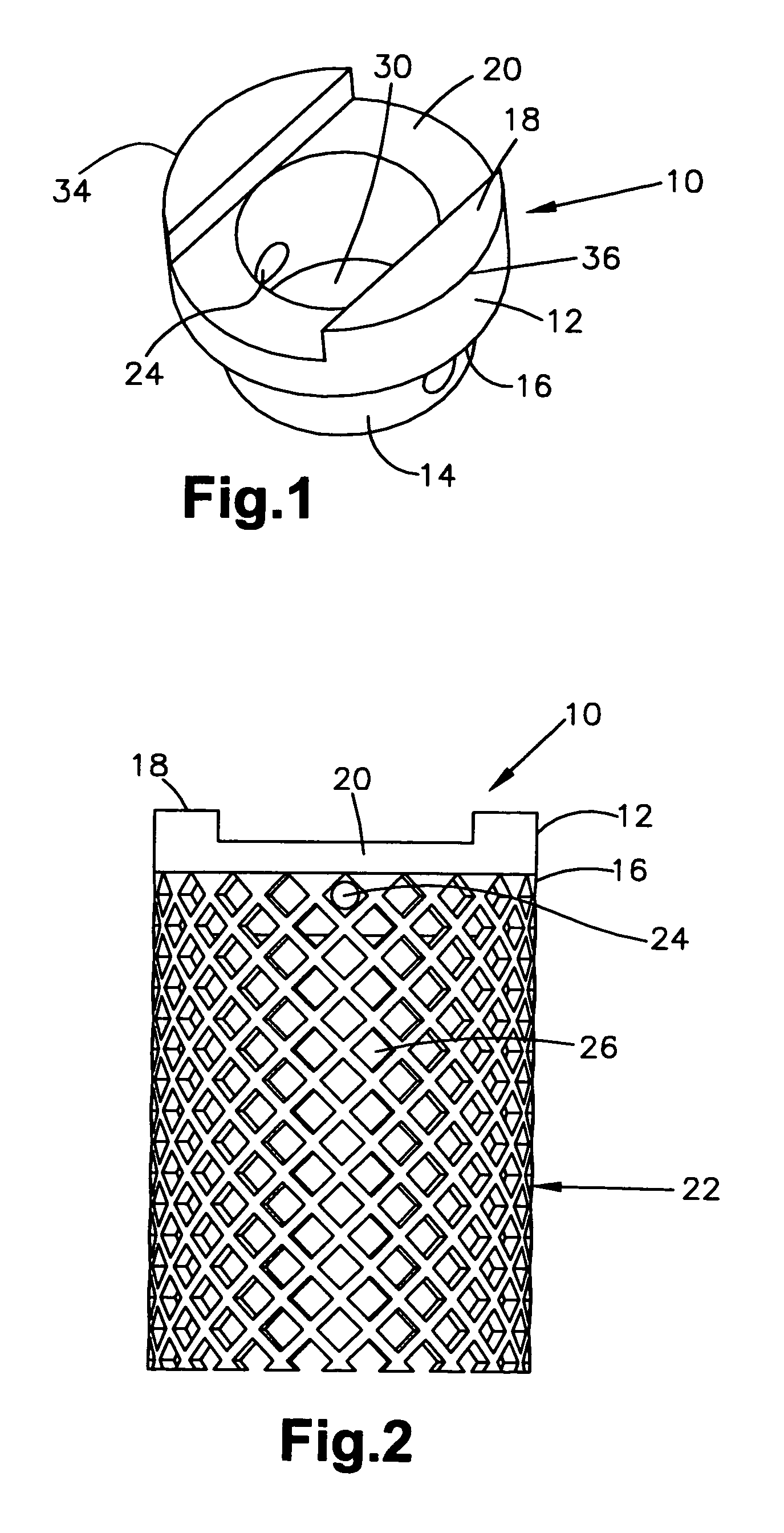

[0031] Second portion 14 is also shown having a round shape. As was the case for top surface 18, second portion 14 can have any suitable shape. Preferably, the shape of second portion 14 matches the shape of the bone fusion implant used with the end member. As best seen in FIG. 2, second portion 14 is si...

second embodiment

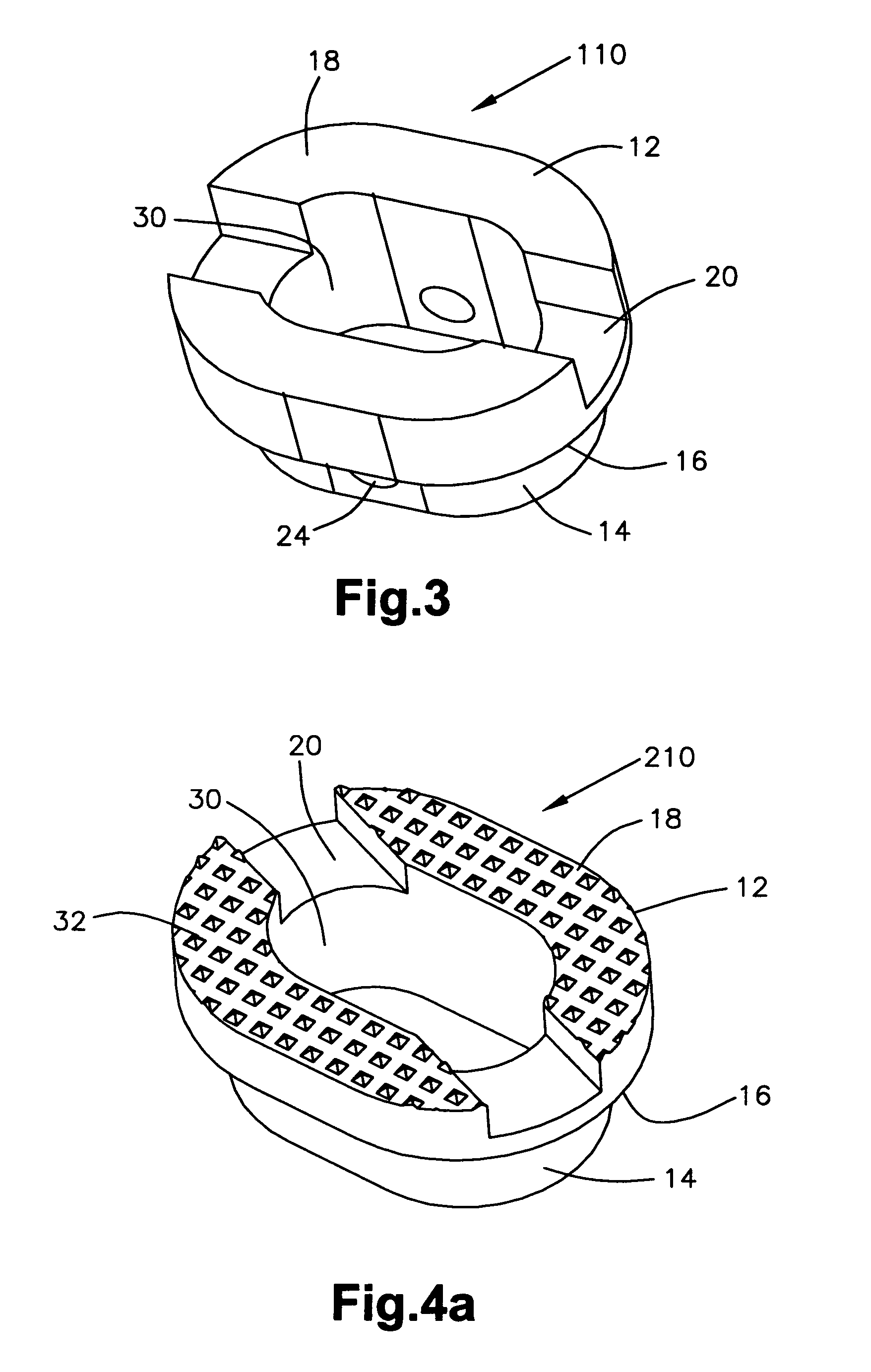

[0033]FIG. 3 shows an end member 110 according to the present invention. In general, most of the structure of end member 110 (as well as the embodiments described below) is like or comparable to the structure of end member 10 and, accordingly the same reference numeral is used for like components and discussion of those like components is not believed necessary. End member 110 has an oval or oblong shape and would be used in situations in which the surrounding bone (and consequently the bone fusion implant) is substantially oval or oblong. When the end member has a non-symmetrical shape like end member 110, first slot 20 can be provided in any orientation. For example, first slot 20 is shown running along the long axis of end member 110, but could run in any direction to be oriented differently with respect to the surrounding bone. The variability in the placement of first slot 20 means that first slot 20 can be positioned as best suited for the particular surgical approach that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com